Machine Safety Systems

Single-Source Safety Solutions

From custom design to installation and integration, PowerSafe delivers machine safety solutions with added features based on each machine's existing controls and infrastructure.

Machine Guarding

Custom designed guards for legacy machines that ensure operators are safe without compromising production efficiency.

Presence Sensing Safety Devices

Proximity-based presence safety devices that deliver real-time feedback to the machine, ensuring operators are at a safe distance during operation.

COMPARE DEVICES

Power Transmission Guards and Covers

Industrial covers, shields, and standard machine guards to mitigate exposure to hazard areas.

Review by Guard Type

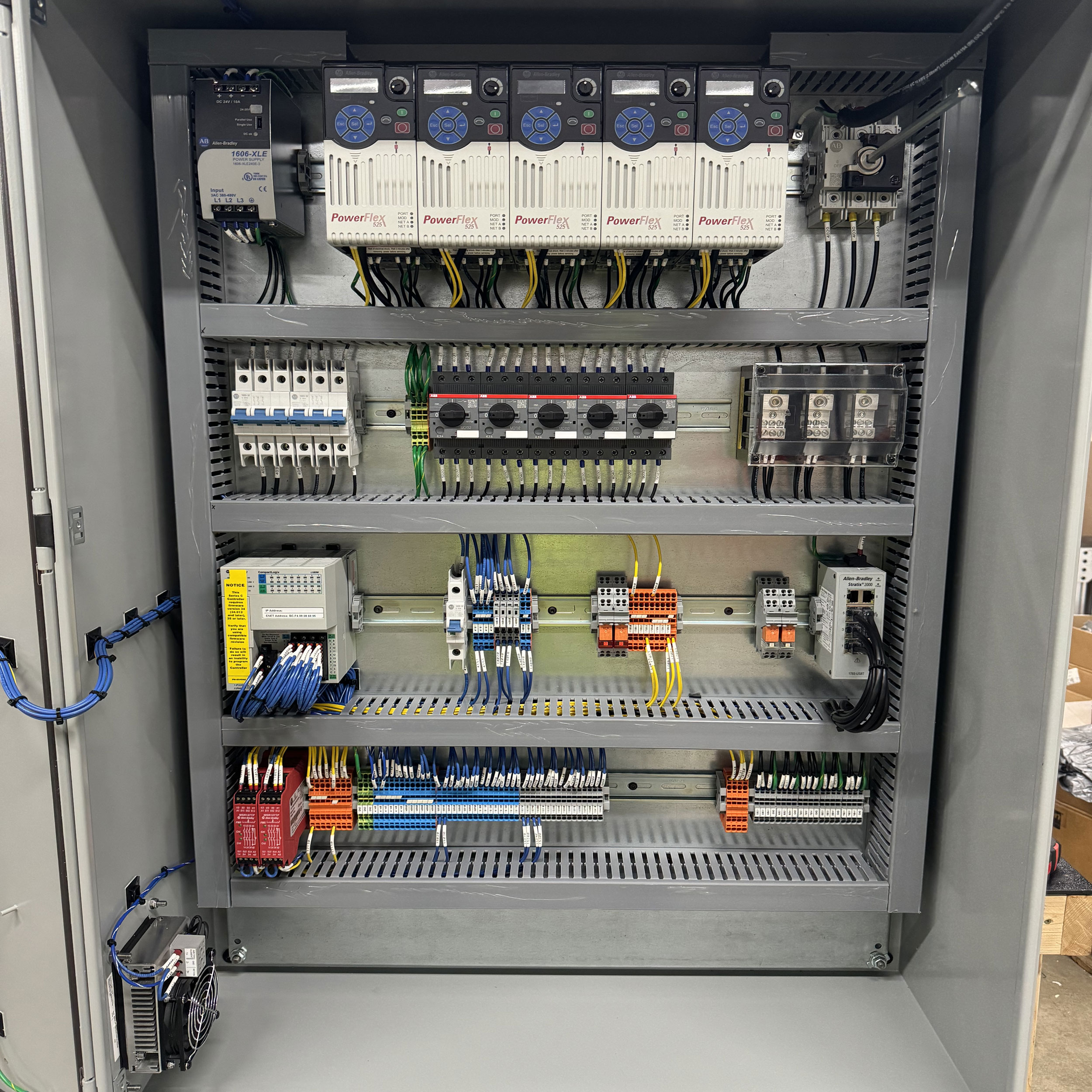

Functional Safety Control Systems

Integrated Safety

Upgrade legacy machine with presence sensing safety devices.

Modernize Your Safety System

Control Reliability

Ensure your safety control circuits meet CAT3, PLd requirements with proper integration between machine controls and safety monitoring devices.