Presence Sensing Safety

Engineered Safety Systems

Upgrade your basic barrier guards to advanced safety systems using electronic safety devices that can detect presence or contact. These devices work with safety relays or controllers to monitor multiple safety functions from one control system.

These devices offer built-in backup systems to help you achieve the highest safety standards for your equipment.

Don't wait for an incident to prioritize safety.

Safety Light Curtains

Light curtains create an invisible safety barrier around hazardous areas on your equipment. We primarily use Keyence and Allen-Bradley brands for reliable performance.

The light curtains are designed for standard applications as well as specialized needs like blanking and muting technology. Safety controllers monitor the system and can be set for either manual or automatic reset depending on how operators need to access the area.

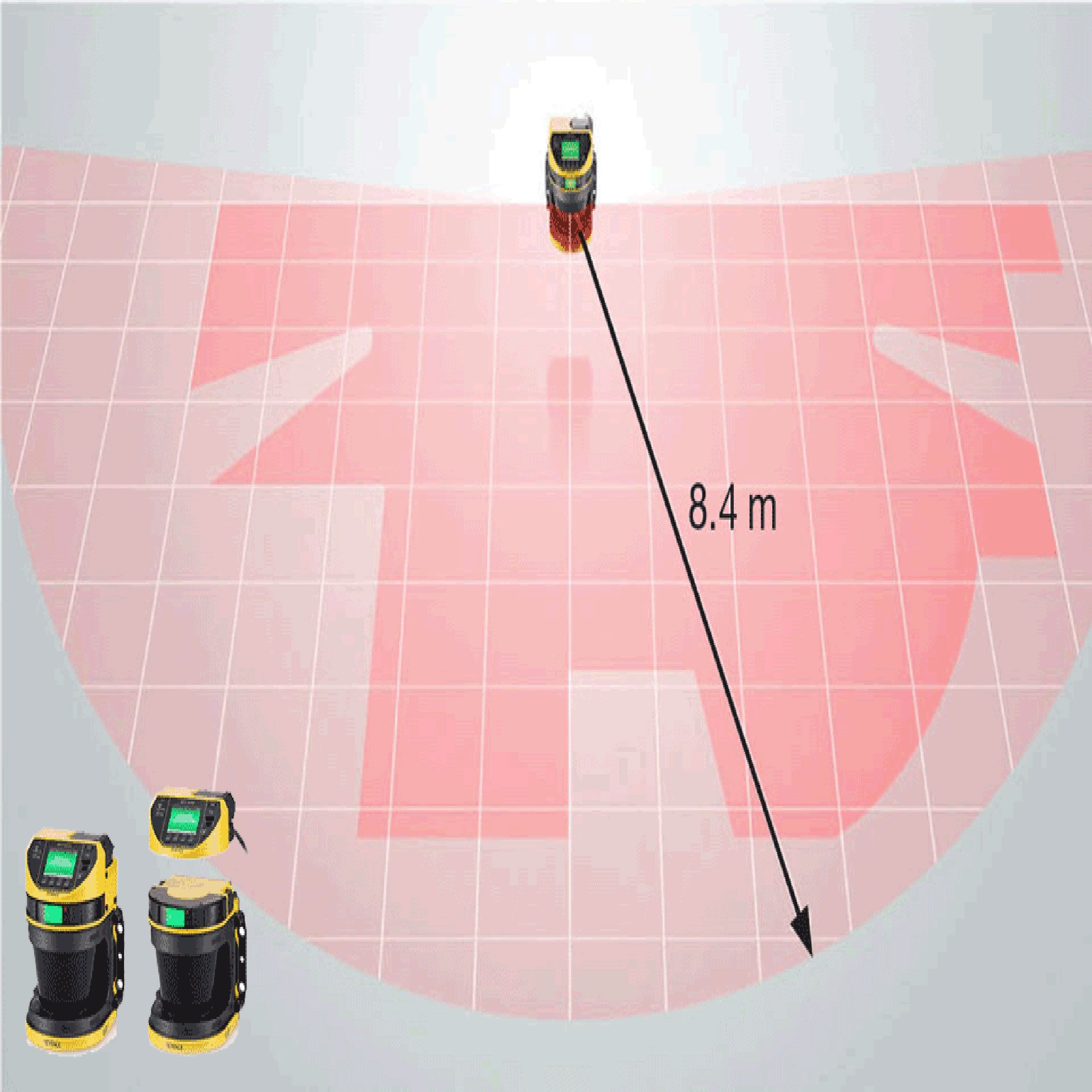

Safety Laser Scanners

Keyence safety laser scanners provide an extra layer of protection in hazardous areas, blind spots, and danger zones. These low-profile units scan up to 27.5 feet in a 190-degree area to detect when someone enters the protected zone.

The scanners are programmable for your specific needs and work with safety relays for backup protection. They're built to resist dust and debris, and optional built-in cameras can collect data for operations or quality control purposes.

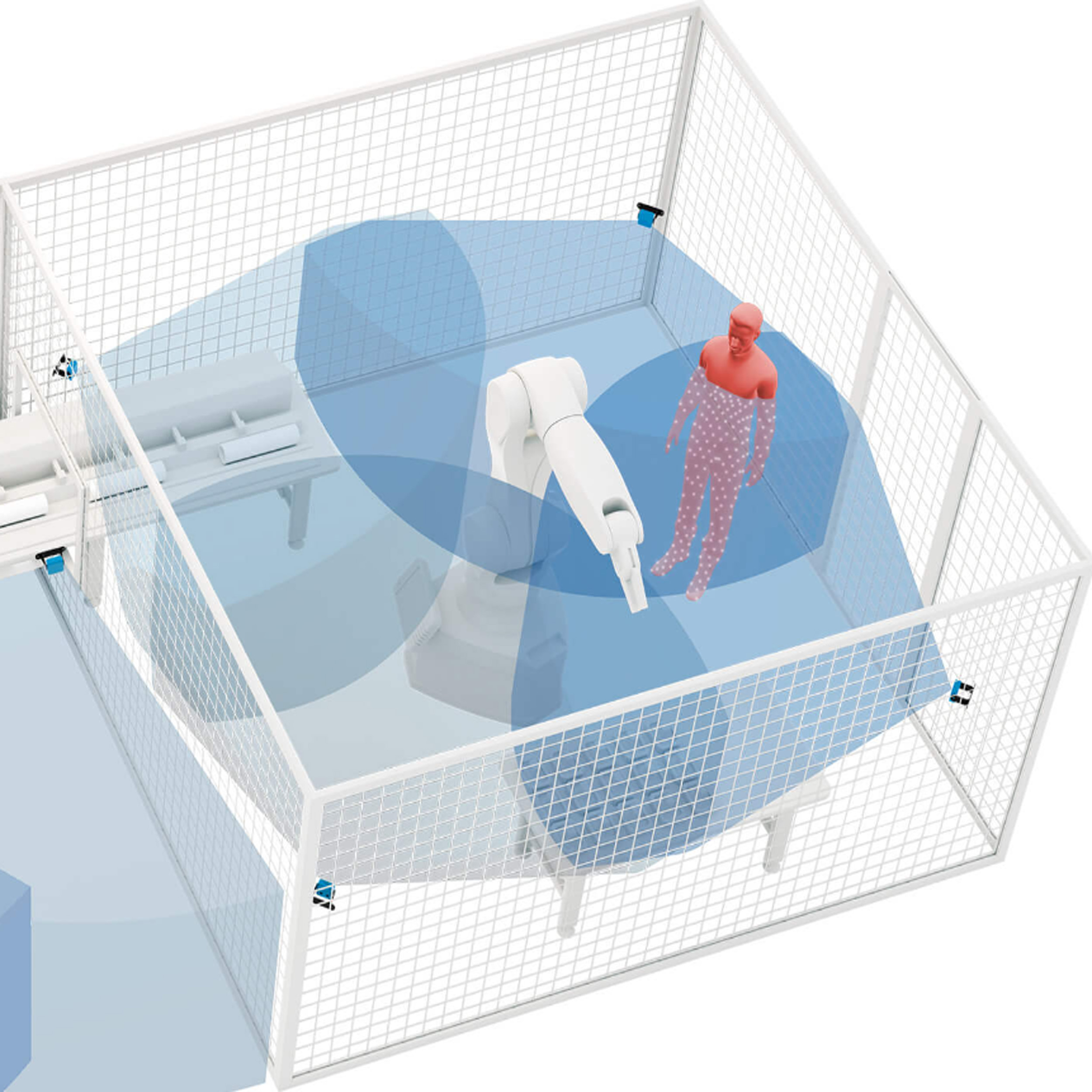

3D Safety Radar

Inxpect Safety Radar uses smart sensor technology to monitor multiple zones and provide three key safety functions: restart prevention, access protection, and anti-collision detection. The system covers up to a 30-foot area in a 100-degree horizontal and 20-degree vertical range.

The radar detects human-sized objects and can extend its range for limb protection using radio signals. Unlike other safety devices, it works reliably in harsh environments with dust, chips, fog, oils, water, and metal shavings.

We can perform feasibility tests with your specific machine setup to determine if this technology is right for your safety guarding needs. Check out safety applications in action →

Safety Switches

Allen-Bradley non-contact safety switches use RFID technology to monitor machine guard doors without physical contact. These low-profile switches resist tampering and allow for door misalignment tolerance. They integrate with safety relays to achieve required safety levels and typically connect to emergency stop circuits with dynamic braking. Complete systems include cables, mounting brackets, and tamper-resistant hardware.

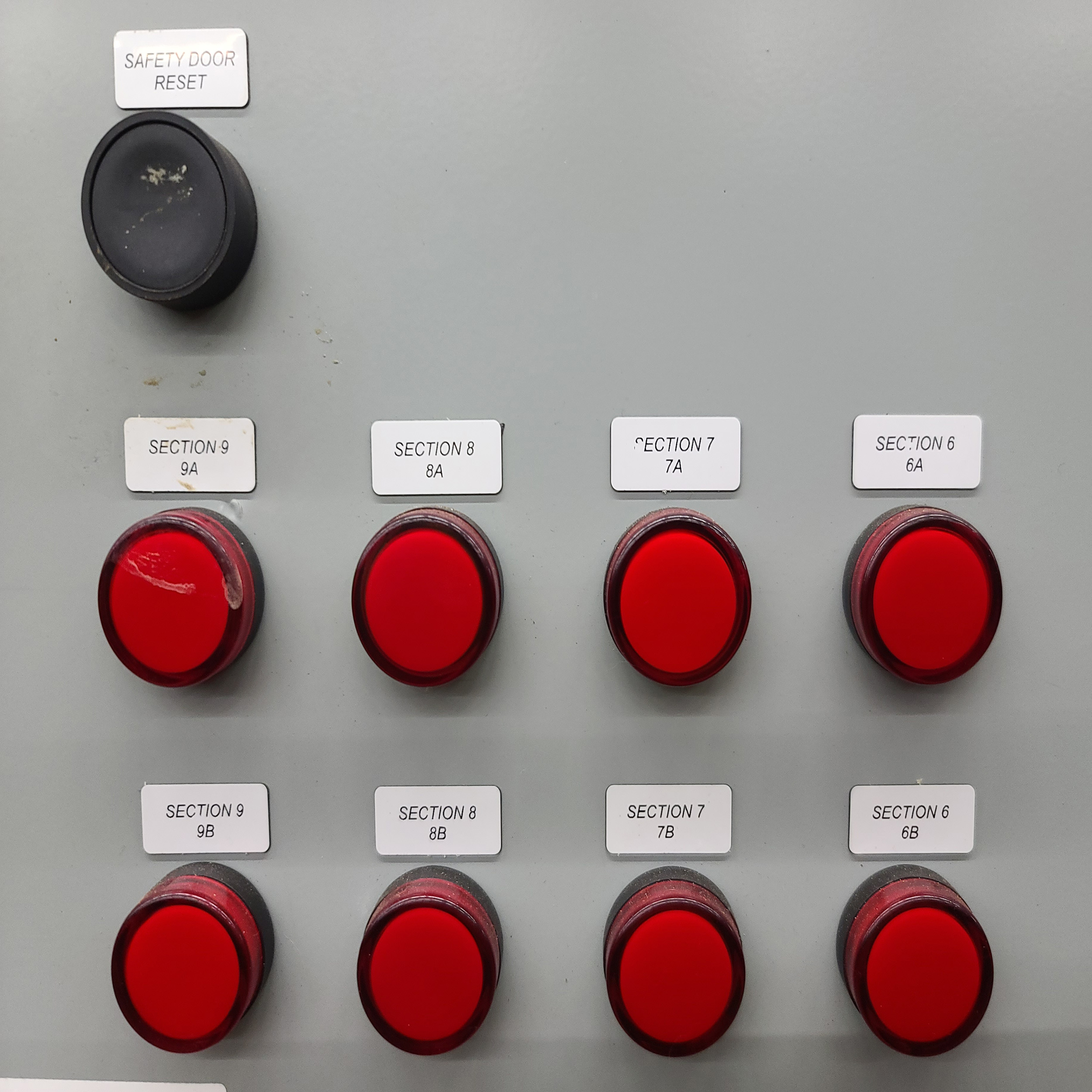

Door Locking Safety

This system keeps guard doors securely closed until machines reach a safe stop. Using Keyence safety interlock switches with RFID technology, the system controls locking solenoids or electrical interlocks. The door only unlocks when an operator signals a safe stop at a control panel. The system uses feedback signals and speed monitoring through Allen-Bradley components, PLCs, and safety controllers to verify zero-speed before allowing access.

Safety Switch Mats

Pressure-sensitive safety mats from Recora Safety, ASO Safety, or Pinnacle Safety detect when someone steps on them with as little as 15 pounds of pressure, immediately triggering a machine stop. Available in custom sizes, shapes, and materials with trim kits for secure floor mounting to prevent trip hazards. Each mat works with Allen-Bradley safety controllers and can be positioned for specific application needs.

Trapped-Key Interlock Safety System

Allen-Bradley trapped key system use a series of mechanical keys and locks to control access to hazardous areas. The initial key deactivates control power and isolates hazards, while additional keys control access throughout the process. This mechanical system requires minimal field wiring and can accommodate single operators or multi-user configurations with key exchange panels and deadbolt latches.

Monitoring Safety Devices

Safety Relays, Controllers, and Safety PLCs

These real-time monitoring devices work with electronic safety equipment to provide the proper redundant safety oversight that standard relays cannot match. Built-in fault detection identifies component failures and functional losses, ensuring the safety system operates correctly and protects machine operators.

Indicator Stack Light

Visual and audio alert systems that communicate machine status to personnel through colored lights and optional buzzers. Mounted on columns or control panels, they typically use green for run, yellow for pause, red for stop, and blue or white for custom processes. Buzzers are available in 85db or 120db depending on environmental needs. Commonly paired with safety laser scanners and 3D safety radars.

PowerControls Safety Enclosure

A pre-built CAT 3 & PLd safety-rated box that's already wired to a power supply and ready to connect safety devices like light curtains, safety switches, and safety laser scanners. The enclosure monitors these safety devices and sends a signal to stop your machine when a safety device is triggered.

All connections are simplified with clear wiring diagrams, making installation and troubleshooting easier.

Custom-Built Safety Enclosures

NEMA-rated enclosures designed and built to your specifications for monitoring individual safety devices at machine entry points. Options include safety relays, controllers, PLCs or mini-PLC controls, air logic components, emergency stops, custom stands, cooling systems, and stack lights with buzzers.

Schematics available upon request.