About Us

Who is PowerSafe Automation?

A Turnkey Machine Safety & Automation Solutions Provider

PowerSafe Automation has created a niche in the market as a turnkey solutions provider focused on custom design, fabrication, and installation for machine safety, electrical, and industrial automation applications. The company was founded in 2016 by elevating commodity products with premium value, through consistent brand recognition and support to the marketplace.

We provide exceptional project execution and consistency to our customers in a compliance-driven industry due to skilled trades and our development and training of a complete infrastructure of policies, procedures, and reporting structure for all facets of our business.

We routinely audit our files to ensure accuracy in a dynamic business platform and to ensure any gaps are identified and remedied.

We have validated our experience through memberships with ISNetworld (hiring client to contractor compliance group), NSC (National Safety Council), ASSP (American Society of Safety Professionals), the BBB (Better Business Bureau), as well as with published articles and award recipients for safety and business.

This allowed us to expand our outreach in networking, provide additional safety training to our employees, and create, upload, & maintain substantial safety programs along with our liability coverage to a trusted platform for clients to review.

PowerSafe Automation’s mission is to solve problems by reducing customer pain points of time constraints, lack of skilled trade, exposure to machine hazards, and liability concerns with improved workplace safety.

We employ industrial engineers who meet with key personnel, such as Safety, Maintenance, and Operations to create synergy in developing the safest solution possible.

This allows us to create a proper machine safety system while still providing the necessary access to the machine for production and maintenance, which is presented to the customer with a fully detailed CAD design.

These systems can range from basic machine guarding to fully integrated machine safety systems. Turnkey designs are achieved through a combination of bolt-on physical guarding, such as T-Slotted Aluminum Extrusion framing with wire mesh and/or polycarbonate plastic panels, machine tool safety guards, and power transmission covers.

These systems are then fully integrated with electronic safety devices, such as safety light curtains, safety switches, safety mats & bumpers, and safety laser scanners along with the necessary safety control circuitry required to integrate into the customer’s machines.

We also provide turnkey solutions requiring additional integration, such as sound blocking materials, automated door assists, integrated timer circuitry, production monitoring systems, and intrinsic safety systems, which are application specific.

Our experienced mechanical and controls technicians build as much of the project off-site including the safety circuits in efforts to reduce production down-time for the client.

Once on-site, the proper training is executed, a jobsite analysis is reviewed, the crew gears up with the proper PPE, and the required lockout-tagout (LOTO) procedures are followed.

The field technicians then install the physical safety guarding commonly consisting of drilling and tapping customer machines and/or drilling the concrete floors, as well as required custom fastening solutions that are application specific.

A “field-fit” service is provided to make sure the physical guarding provides the proper protection required.

The electronic safety devices are then mounted and integrated by our controls technicians into the client’s required e-stop circuit through our own designed PowerControls machine-to-safety device integrator.

This is followed by the device and circuit validation for reliability and proper functionality, which includes the proper safety relays or safety controllers and power supplies.

The electronic safety devices in conjunction with our PowerControls enclosure allows the ability to achieve the highest safety category level required for each specific machine guarding application.

Meet Our Team

We believe everyone deserves to go home safe to their families every night. At PowerSafe, we've made it our mission to accomplish that in-house and for you.

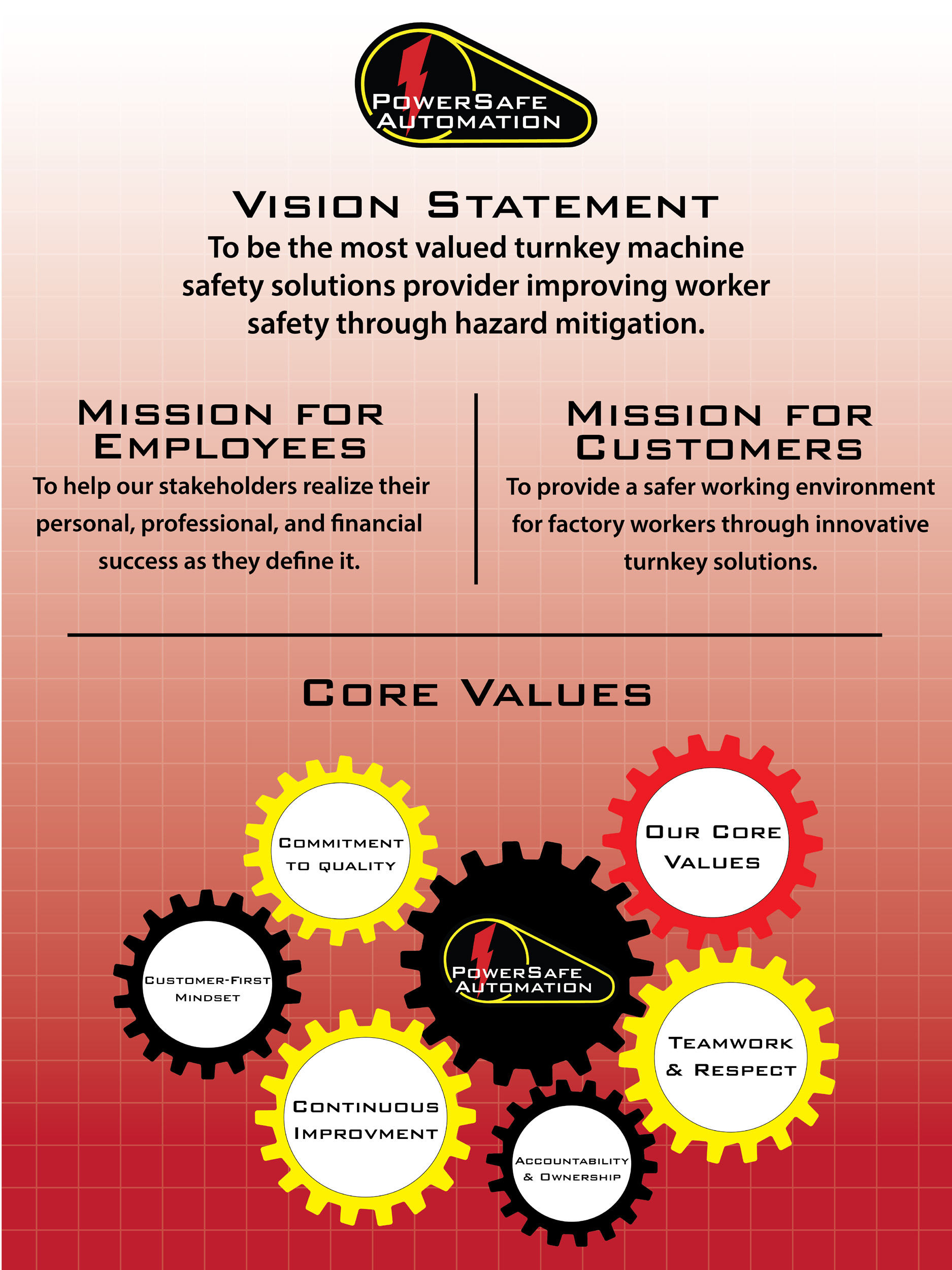

Our Core Values

Small town USA with global quality standards, PowerSafe values as it relates to beliefs and principles that help guide behaviors through leadership and accountability as a tool to help with our mission and vision, its customers putting in the extra time and effort getting the job done and reducing your pain points.

Our Company Culture

Mission for our employees: To help our stakeholders realize their personal, professional, and financial success as they define it.

Mission for our customers: To provide a safer working environment for factory workers through innovative turnkey solutions.

Vision is our painted picture built off the foundation of our mission statements and core values.

Our Quality Statement

Quality is EVERYONE'S responsibility through the empowerment of self-checking without relying on a dedicated quality control person to catch your mistakes. We will focus on the "Chasing Perfection" philosophy to quality, continuously improving our systems, processes, training, and consistently providing solutions that meet or exceed the expectations of our customers and stakeholders.

Where we started and where we're at

Our Story

In the summer of 2015, Shawn Mantel, a Sales Engineer, and a previously partnered Electrical Contractor, were at a crossroads in their careers and both were looking for something more for their family and friends.

Conversations began about each other’s respective backgrounds at a seasonal campground drinking Fireball Whisky around a campfire.

They quickly realized they could join forces to offer the market something unique and decided they could exploit a void in the market with their skills and abilities. This combined skill set could give workers a better chance to go home safe at night to be with their families, just as they did.

With a gap in machine safety systems between mechanical processes and machines, expanding regulations and standards, and the new generation of computer controls and robots there was a need for a company to provide skilled trade services of installation and electronic safety device integration and support. That casual conversation quickly became reality and PowerSafe Automation was founded.

Our Historical Milestones

Established in January 2016, PowerSafe Automation carved a niche in the market by offering custom machine safety guarding, electrical, and industrial automation solutions. Their efforts quickly paid off as they gained new customers, including Fortune 500 companies. In the fall of 2016, they purchased a 14,000 sq ft facility, expanded their team, and enhanced their online presence, positioning themselves for future growth and better customer service. They also became a member of ISNetworld, a reputable compliance partner, ensuring adherence to liability insurance, OSHA logs, and safety programs.

With no end in sight, they continue to focus on new ways to expand the business and their outreach, grow relationships with their customers which include Fortune 500 companies. Most importantly, they continue to save people’s lives by improving their workplace safety while reducing pain points.

Elevating Commodity Products with Premium Value Solutions

- Our commitment to machine guarding compliance

- Third-party compliance verification:

- ISNetworld Compliance #400-24372

- SAM member with a CAGE number 84QU7

- NSC and ASSP safety members

- SIC code 3569 – General Industrial Machinery and Equipment

- NAICS code 423830 – Industrial Machinery and Equipment Merchant Wholesalers

- Due to comprehensive services, including machine safety guarding, electrical integration, and industrial automation solutions, other NAICS codes have alignment such as:

- 334519: Other Measuring and Controlling Device Manufacturing

- 335999: All Other Miscellaneous Electrical Equipment and Component

- 423420-04: Automation Systems & Equipment (Wholesale)

- Due to comprehensive services, including machine safety guarding, electrical integration, and industrial automation solutions, other NAICS codes have alignment such as:

- Certificate of liability insurance (COI) documents available

- Solutions created with the understanding of machine guarding compliance:

- Technical support team

- Strong streamlined supplier network

- Minimized production downtime

- Inventory of standard products

- Modern machine resources

- Real-time field-fit configuration

- Flexible scheduling

- Machine guarding assessments

Success Story

One success story we are proud to promote is our speed monitoring system. After attempts with other suppliers, a client contacted us with a problem looking for a unique solution. Their current situation had an old lathe with a simple barrier guard and a non-locking safety switch on the door. This machine took 15 seconds to ramp down allowing the operator to be exposed to the hazards once the non-locking door was opened. We designed a speed monitoring system using an encoder, a proximity sensor, and a locking solenoid switch controlled by our PowerControls. This kept the door locked until the speed monitoring system sensed the lathe was at zero rotation eliminating the hazard presence to the operator. We were just published as an authority for this application in the June 2018 issue of Assembly Magazine.

PowerSafe Automation helps improve the safety attitudes of employees in the workplace, which allows us to have a high customer retention rate by providing the client with an exceptional value for their money focusing on quality, reliability, and service

- We provide consistency throughout the entire custom design thru installation process ranging from a single facility to Fortune 500 companies with multiple locations nationwide.

- We believe communication is a key factor in building long term customer relations.

- We hold internal pre-jobsite meetings to properly prepare for the project, as well as hold post jobsite meetings to discuss the successes and challenges of each project.

- This allows us to build a safer work environment for our clients by providing continual improvement to the marketplace while lowering the statistic of OSHA machine guarding methods standard 1910.212 being the 9th most-cited OSHA violation.

LEGACY Machines...we can make them safer with modern technologies.

As a single source provider of industrial solutions, Fortune 500 manufacturers deem us essential to worker's safety and well-being through collaboration due to our compliance-driven machine guarding installation solutions.