Integrated Machine Safety Controls

Bring Safety to Legacy Machines

We combine modern safety expertise with creative engineering to design custom guarding systems for your outdated equipment. By integrating physical guards with advanced electronic safety devices and automation controls, we protect your operators while keeping production running smoothly and efficiently.

Intrinsic or HazLoc Safety Systems

Safety systems designed and rated for Class 1, DIV 1 or DIV 2 explosive environments. These systems protect workers and equipment by preventing electrical sparks and ignition sources in explosive environments.

Zero-Speed Detection Safety System

Zero-speed detection systems monitor machine motion and verify safe stops before granting operator access.

These systems prevent accidents by ensuring machinery has reached a safe, motionless state through electronic feedback monitoring before workers can enter hazardous areas or perform maintenance tasks.

Vertical Safety Doors

Vertical safety doors improve workspace accessibility while maintaining full safety protection. These space-saving doors integrate with safety controls to protect operators without compromising floor space or workflow efficiency.

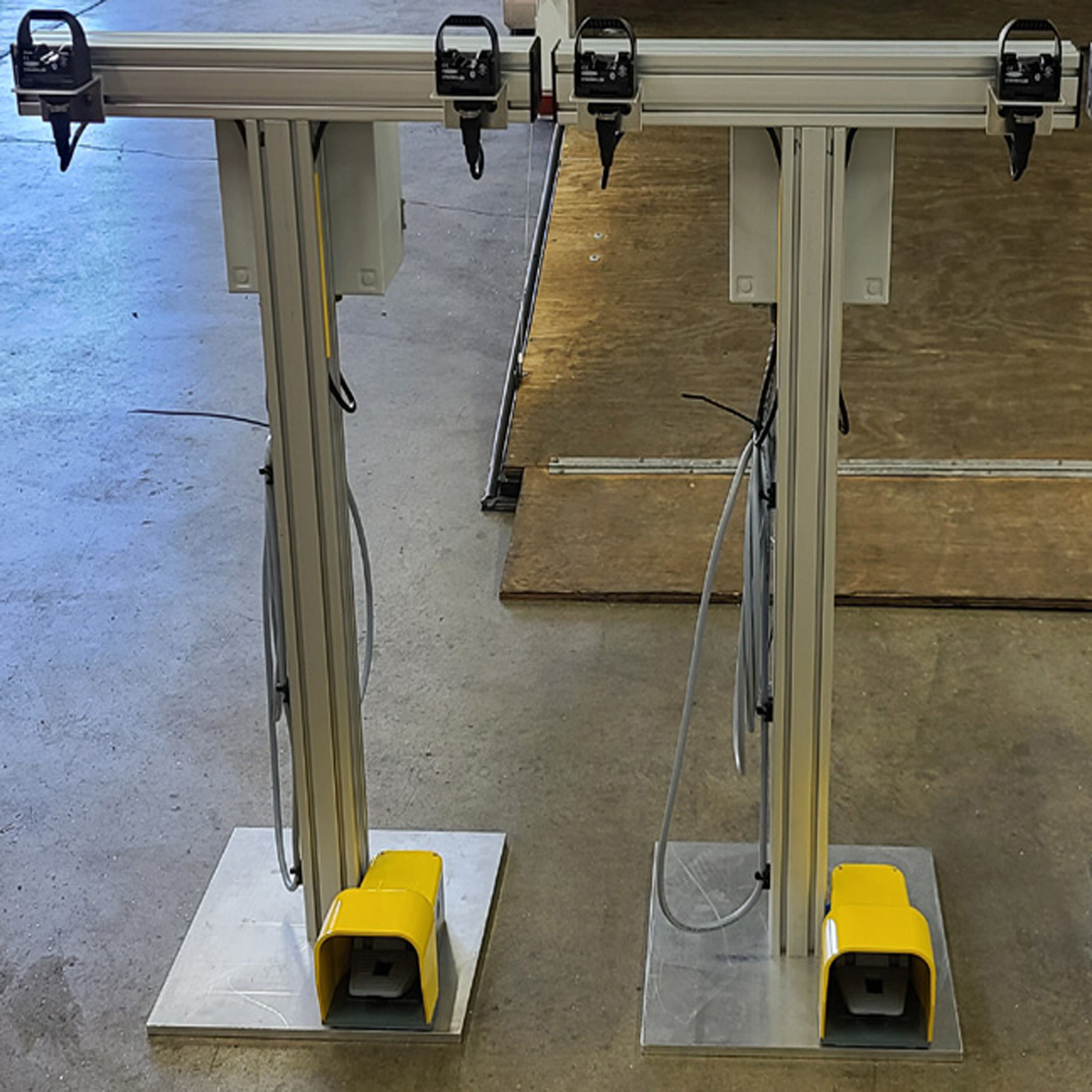

Two-Hand Controls

Two-hand controls require operators to use both hands simultaneously to start machines, ensuring hands are safely away from hazardous areas during operation. Built-in anti-tie-down features prevent operators from bypassing the safety system.

Available with custom spacing, height adjustments, and mounting options.

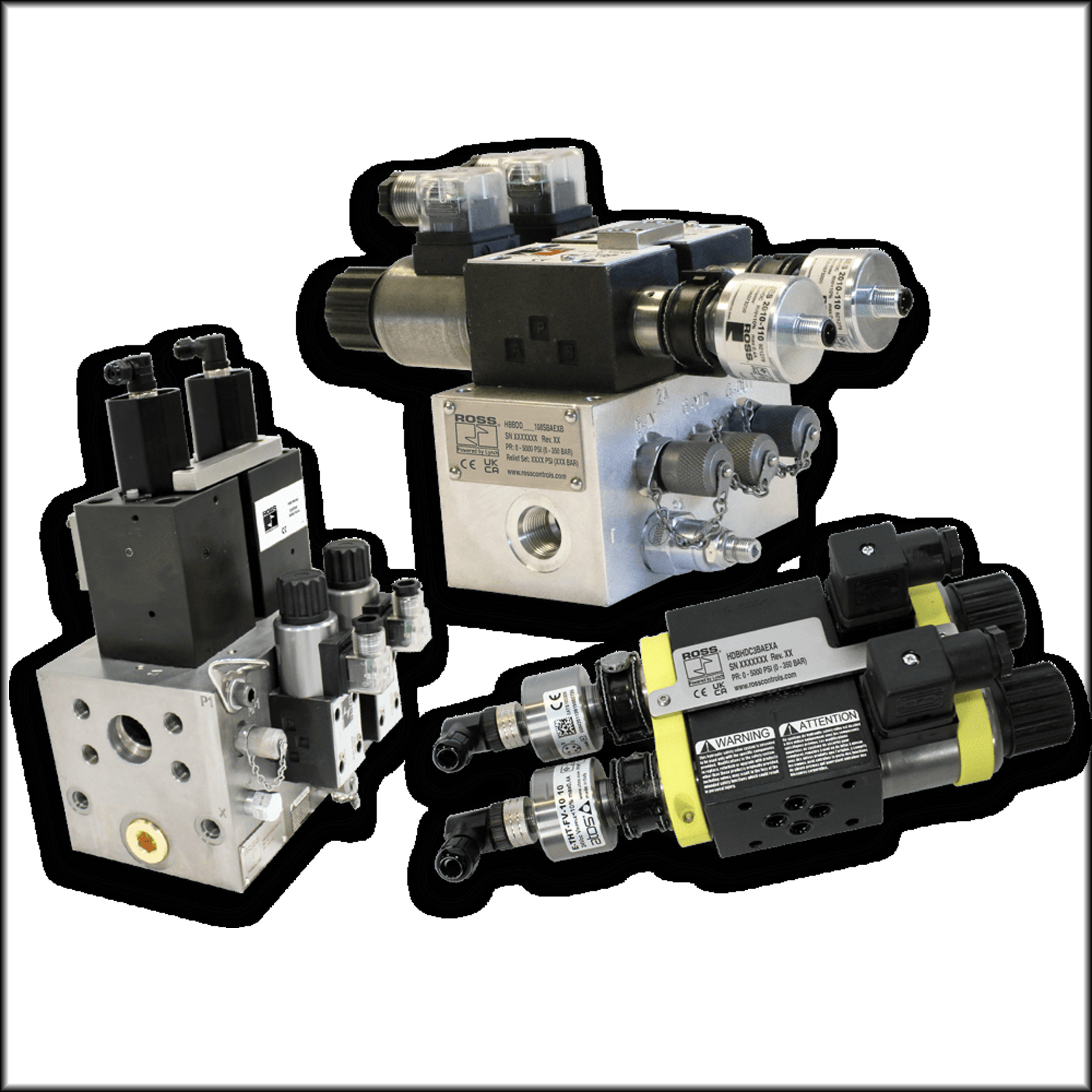

Fluid Power Safety Systems

Pneumatic Safety Controls

Pneumatic safety controls protect operators by safely managing stored energy from compressed air systems and preventing unexpected machine motion during maintenance or operation.

Hydraulic Safety Controls

Hydraulic safety controls safeguard operators by regulating stored energy in pressurized systems, preventing system failures and unsafe motion that could cause injury.

Emergency Stop Devices

Pushbutton and Pull Cords

Wired emergency stop devices, which are energy isolation devices, not safety devices, are available in single or dual channel configurations. Options include standalone pushbutton boxes, pushbuttons integrated into control panels, and emergency rope pull devices that comply with ISO 13850 standards.

All devices include required labeling and hardware to provide immediate machine shutdown when activated.

Wireless E-Stop Controls

Wireless emergency stop devices provide mobile shutdown capability that moves with operators throughout the work area, ensuring immediate machine shutdown access for operator protection regardless of location.

Grip Enabling Switch

Grip enabling switches, also known as deadman or liveman switches, combine engineered solutions and admin controls to keep operators safe during maintenance or setup operations by automatically stopping machines when released or improperly held, ensuring continuous operator control.

Press Brake Safety Systems

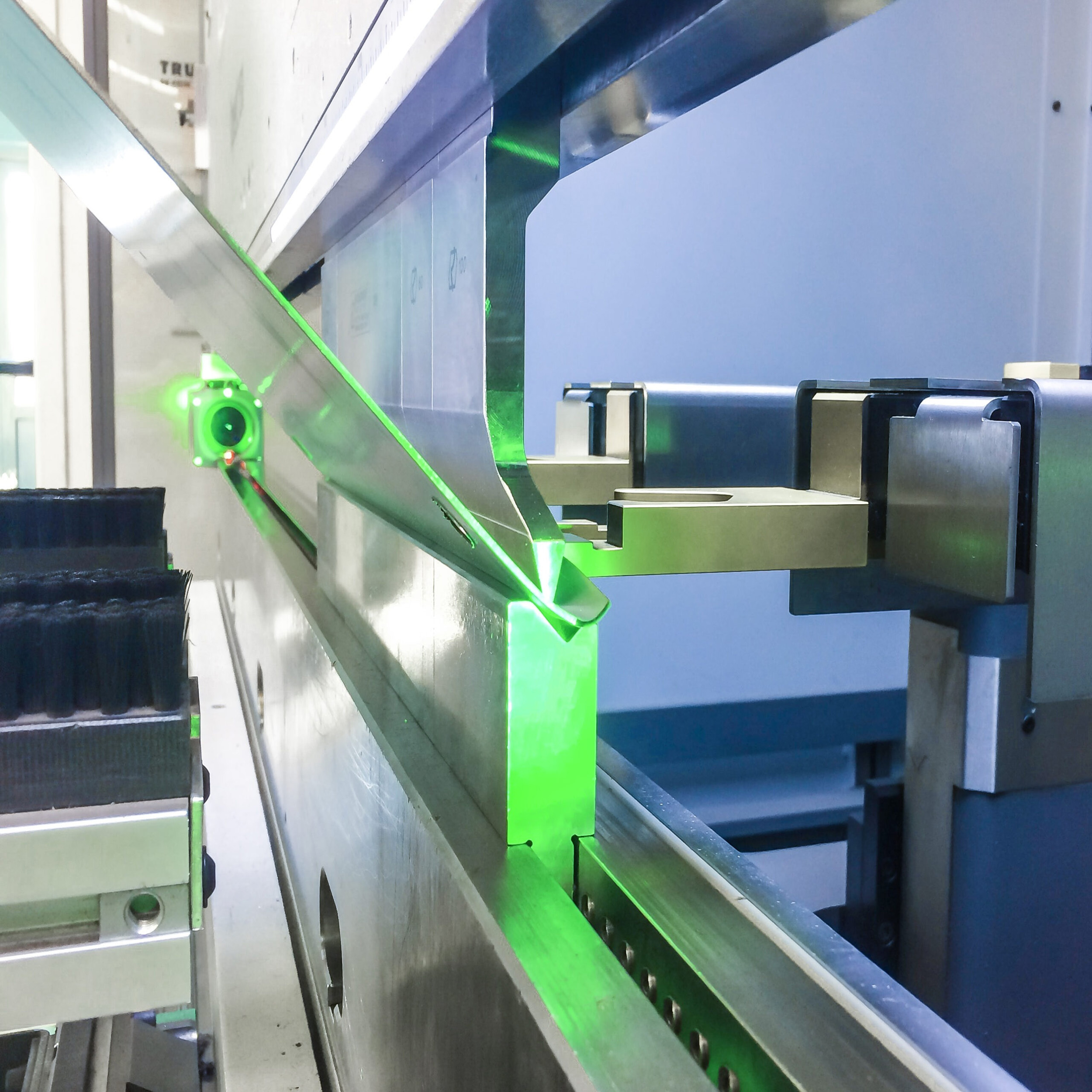

Press Brake Profiling Curtains

Boost press safety with ProTech Eagle Eye Profiling Light Curtains, advanced optical protection with dynamic blanking, fast response, and rugged reliability for industrial machines.

Camera-Based Press Safety

Improve press brake safety with LazerSafe’s camera-based safety system from PowerSafe Automation, high-precision optical protection, fast setup, and reliable performance for modern forming operations.

Press Die Blocks with Safety Interlocks

Die blocks with safety interlocks secure press machines during maintenance by preventing accidental ram movement and protecting operators from crushing injuries.

CNC Machine Risk Reduction Devices

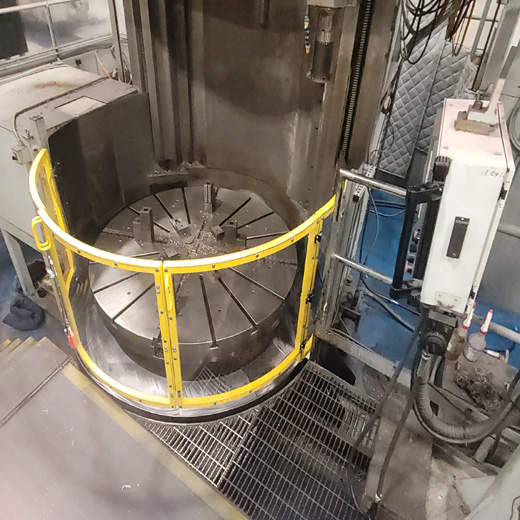

Vertical Turret Lathe Guarding

Custom-designed guards protect operators by containing rotating hazards, flying chips, and coolant spray while maintaining clear visibility for safe operation.

CNC Machine Safety Switch Retrofits

Safety switch upgrades require a professional assessment to review your machine controls and determine feasibility. E-stop buttons alone do not provide adequate operator protection under OSHA standards.

CNC Viewing Window

CNC spin windows and clear screens enhance operator safety by providing unobstructed machine viewing without opening guard doors. These solutions contain chips, coolant, and debris while maintaining full visibility of your machining process.

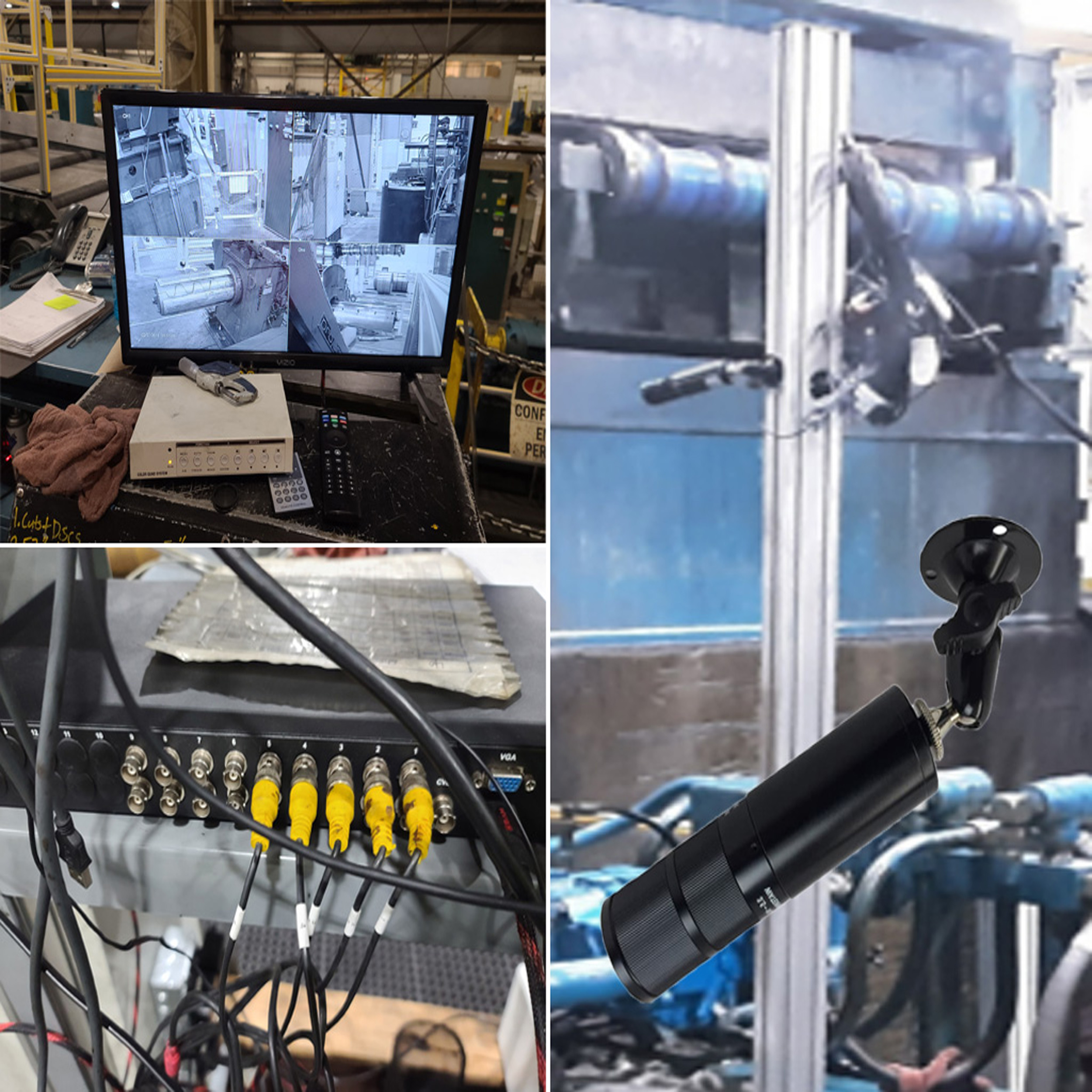

Camera Monitoring System

Camera systems improve visibility and monitoring for operators in blind spots and hard-to-see areas.

However, these are a non-safety rated solution do not replace certified safety devices required for personnel protection.