Machine Guards and Shields

User-Friendly Guards and Shields

From forgotten equipment to machines in experienced hands, proper guarding is required on all shop floor equipment regardless of operator expertise. OSHA standards don't make exceptions based on skill level.

Our turnkey machine guards, anti-restart devices, safety switches, and LED work lights are specifically designed with machinists in mind for easy integration and use.

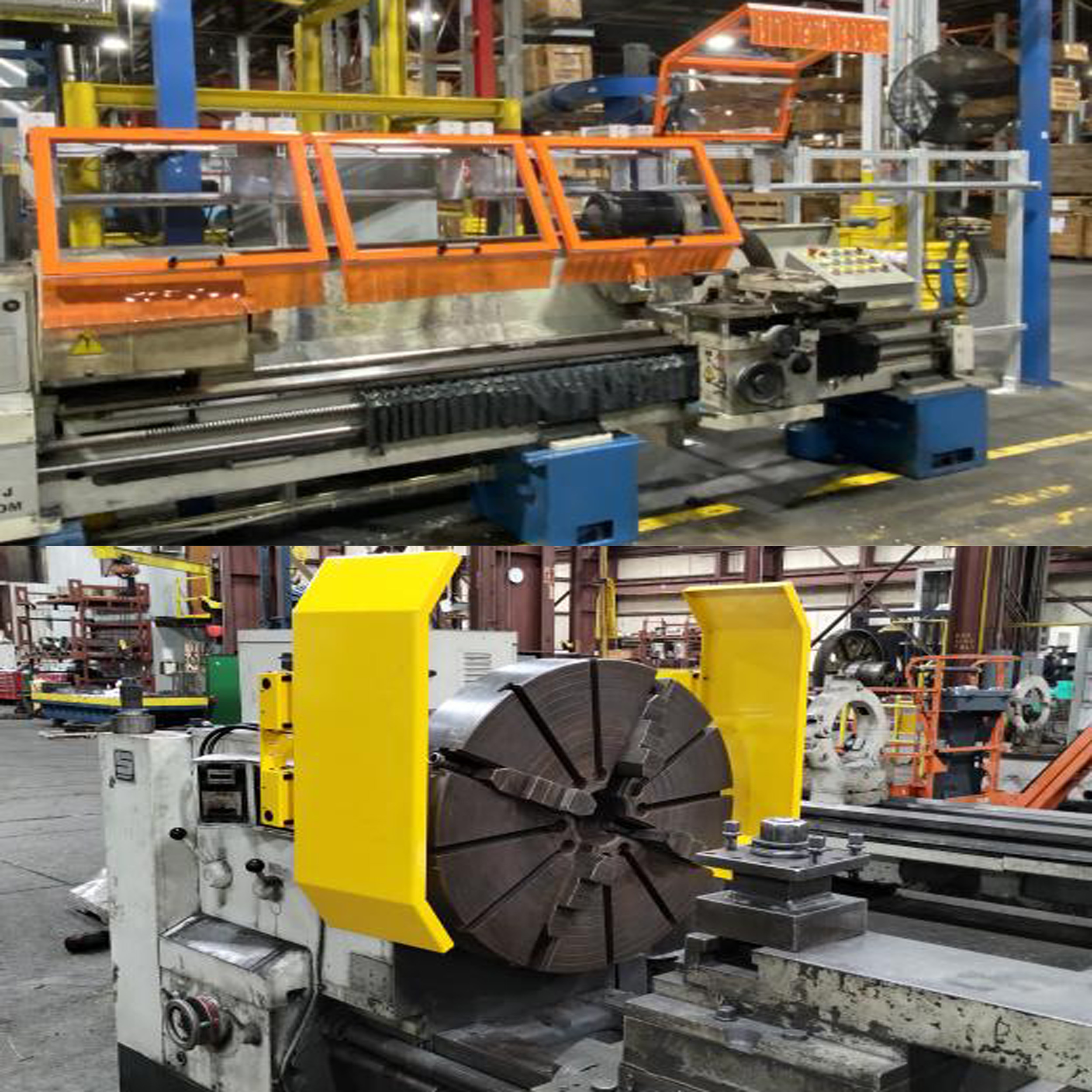

Standard Manual Lathe Guards

Chuck and lathe guards feature safety orange powder-coated aluminum with clear polycarbonate panels for visibility. Available as hinged lids or sliding rail systems that mount to the machine or floor. These guards include safety switches for machines up to 480V and authorized bypass keys for secondary operations like polishing and deburring.

They protect against sharp metal curling, pull-in hazards, cuts, and coolant spray. Vinyl strips can be added for flexibility at tool rests. Compatible with most lathe brands including Harding, Jet, Baileigh, and Kent.

Custom Large Lathe Guards

Chuck and lathe guards available as hinged lids or sliding rail systems that mount to the machine or floor. These guards include safety switches for machines up to 480V and authorized bypass keys for secondary operations like polishing and deburring.

Check out the ANSI B11.6 specifications

Milling Machine Guards

Modular guarding systems for manual mills and CNC bed mills with mounting options for rams or heads. These guards prevent flying chips, entanglement, cuts, crush and shear hazards, and coolant spray. The high-visibility aluminum structure with articulating arms provides user-friendly operation for experienced machinists while accommodating various tooling, fixtures, and material sizes.

Safety switches handle 110VAC to 480V and interrupt spindle motors to prevent hazards. Compatible with Bridgeport, Jet, Lagun, Clausing, Trak, Sharp, and other mill brands.

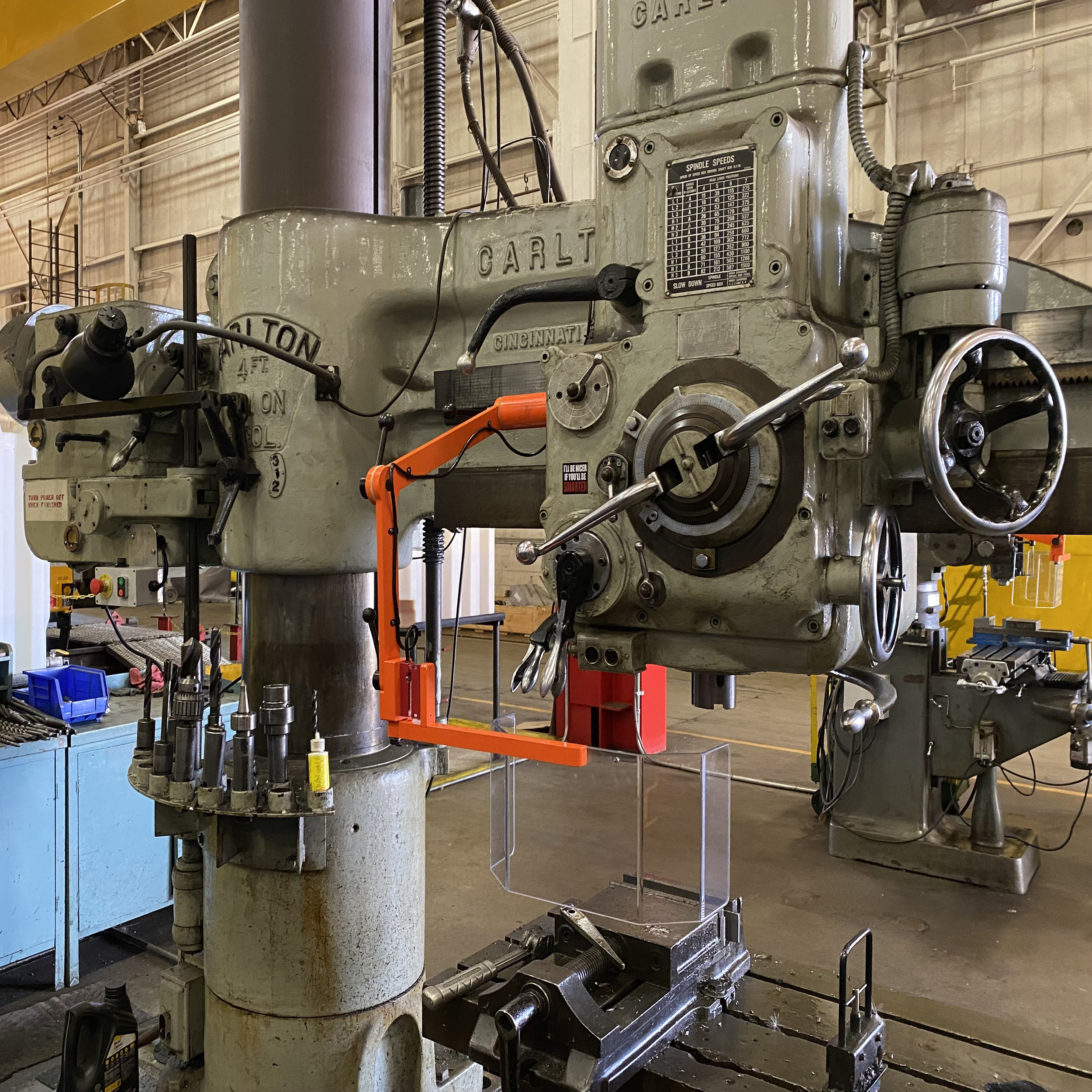

Radial Arm Drills and Drill Press Guards

Adjustable column-mounted and universal pattern guards minimize metal shavings, reduce cut hazards at drill bits, prevent entanglement at rotating spindles or chucks, and eliminate slip hazards from coolant spray. Safety switches increase protection levels for machines from Jet, Delta, Powermatic, Clausing, and Baileigh. Large radial arm drills can include additional safety mats or physical guarding at the back of the machine.

Tool Grinder / Sharpener Guarding

Improve operator safety by containing sparks, debris, and rotating hazards while enhancing visibility.

General Shop Press

Steel mesh curtains for hydraulic shop presses guard against material ejection, parts under pressure, and breakage fragments during pressing operations. Split curtain design with front and back rods provides flexibility for long parts while maintaining visibility and optimized protection from rams or dies. Available with safety interlocked doors using clear polycarbonate panels for low-profile parts requiring safety verification.

We can also install a machine guard for small parts contained within the machine envelop.

Bench Grinder and Buffer Shields

Machine shields protect eyes, face, and body from flying debris, fragments, sparks, and rotating grinding wheels. Deflectors angle material ejection downward to manage mess and debris. Metal-framed polycarbonate shields provide work visibility with optional side guards for additional protection. Tongue guards should be adjusted within ¼" and work rests within 1/8".

Belt and/or Disc Sander Shields

Adjustable guards for single or combination sanding machines covering unused sanding surfaces during finishing operations. These guards prevent cuts, burns, abrasions, nip points, and entanglement hazards where belts or discs meet pulleys. Available for various sanding belt widths and disc diameters.

Vertical Bandsaw Guards

Shop-use bandsaw guards feature polycarbonate panels for clear part visibility with multi-directional adjustability. These guards prevent accidental contact with moving saw blades during material feeding, reducing cuts, lacerations, amputation risks, and metal shavings. High-visibility orange extrusion accommodates various product shapes.

Vertical Bandsaw Guarding System

Production bandsaw systems integrate safety light curtains on rigid posts at operation points with machine guarding around sides and back. These prevent cutting, shearing, and entanglement hazards while maintaining access to chip trays and blade changes without interrupting hydraulic functionality. Remote cycle start and emergency stop buttons available when controls are located in safety zones.

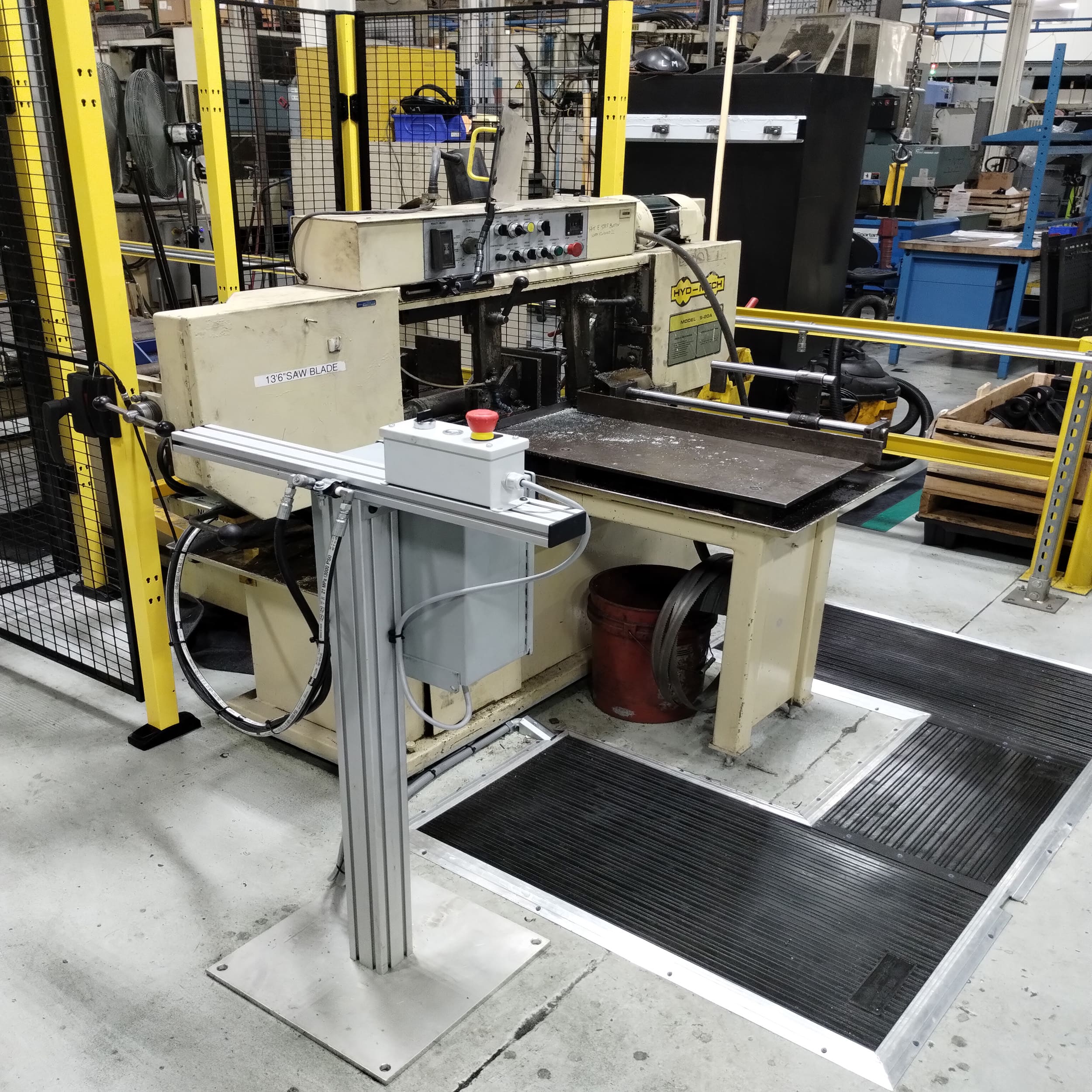

Horizontal Bandsaw Guards

Shop-size equipment guards feature safety-switched hinged designs with polycarbonate panels for clear part visibility and vinyl strips for material variability. These high-visibility safety guards prevent accidental blade contact and minimize exposure to shear points, cut hazards, and limb loss.

Horizontal Bandsaw Guarding System

Production equipment systems combine safety switch mats or laser scanners with protective bollards at front, physical guarding at back, and remote blade start stations with emergency stops on pedestals. These keep operators away from hazardous cutting and clamping areas, preventing reach-in accidents and loose clothing entanglement while maintaining hydraulic energy for blade changes.

Info on ANSI B11.10-2003 safety standards

Surface Grinder Guards

Machine safety enclosures prevent nip points, cuts, and burns from direct grinding wheel contact. Guards also protect against wheel shattering or explosion from defects, coolant issues, excessive force, and thrown objects when magnetic chucks aren't activated. Typically supplied without safety switches due to grinding wheel temperature requirements.

Check out ANSI B7.1 or under ANSI B11.9 for more information.

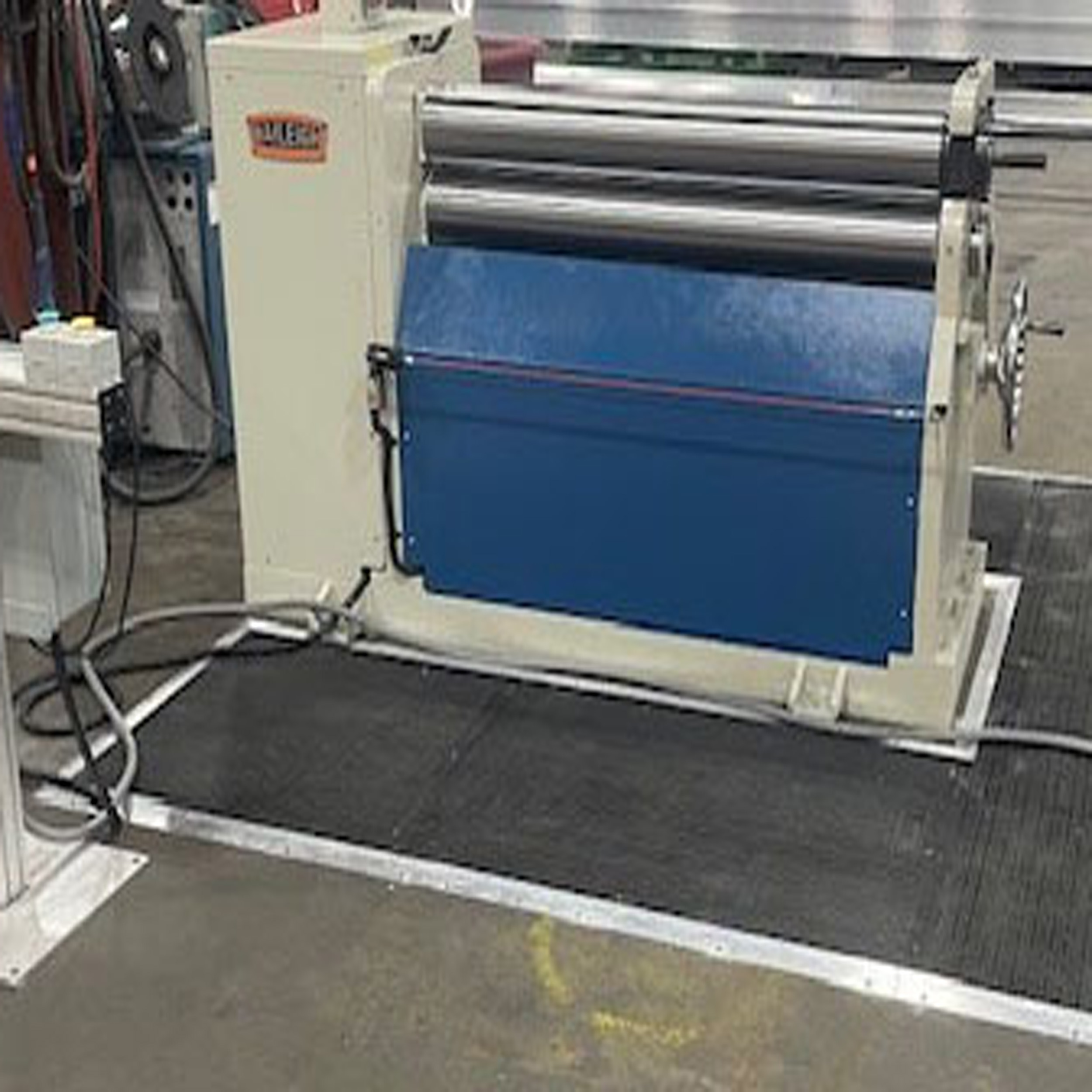

Plate Roller Safety

Machine safety packages protect operators and bystanders from in-running nips, crushing hazards, pinch points, and entanglement on power-driven rolling, forming, or bending equipment. Solutions include custom safety mats around rollers monitored by safety controllers and pedestal-style two-hand operator control stands. Emergency rope pull stops available for additional protection.

Shear-Nip Guarding

High-strength, round bar finger guards custom-fit to bolt on at operation points, protecting workers from cuts, lacerations, shear and crush hazards, and amputations at moving blades. Additional guards cover exposed gears, sprockets, and chains on sides, with perimeter guarding featuring safety gates and switches tied to emergency stop circuits to prevent back-of-machine access.

Go to ANSI B11.4 for machine standards

Anti-Restart Control Box

An anti-restart device prevents machines from automatically restarting after a power interruption or outage. The device ensures operators have full control over when equipment resumes operation, protecting against unexpected startups that could cause injury or damage.