Flexible Manufacturing Solutions

Manufacturing Optimization

PowerSafe partners with Bosch-Rexroth in Germany to align process improvements, efficiency, quality, and safety with U.S. market needs.

Ergonomic Workplace Safety Solutions

Boost workplace safety and productivity with ergonomic workstations that reduce discomfort, improve attendance, and enhance employee performance.

Lean Manufacturing

Optimize assembly lines with 6S: small-batch flow, streamlined value streams, and safety-driven 5S practices to boost efficiency and scalability.

Process Flow Improvements

Shop Floor Solutions

You Visualize, We Modulize!

Boost shop floor efficiency with modular T-slot aluminum solutions—custom carts, benches, shelves, and bases designed for workflow improvement.

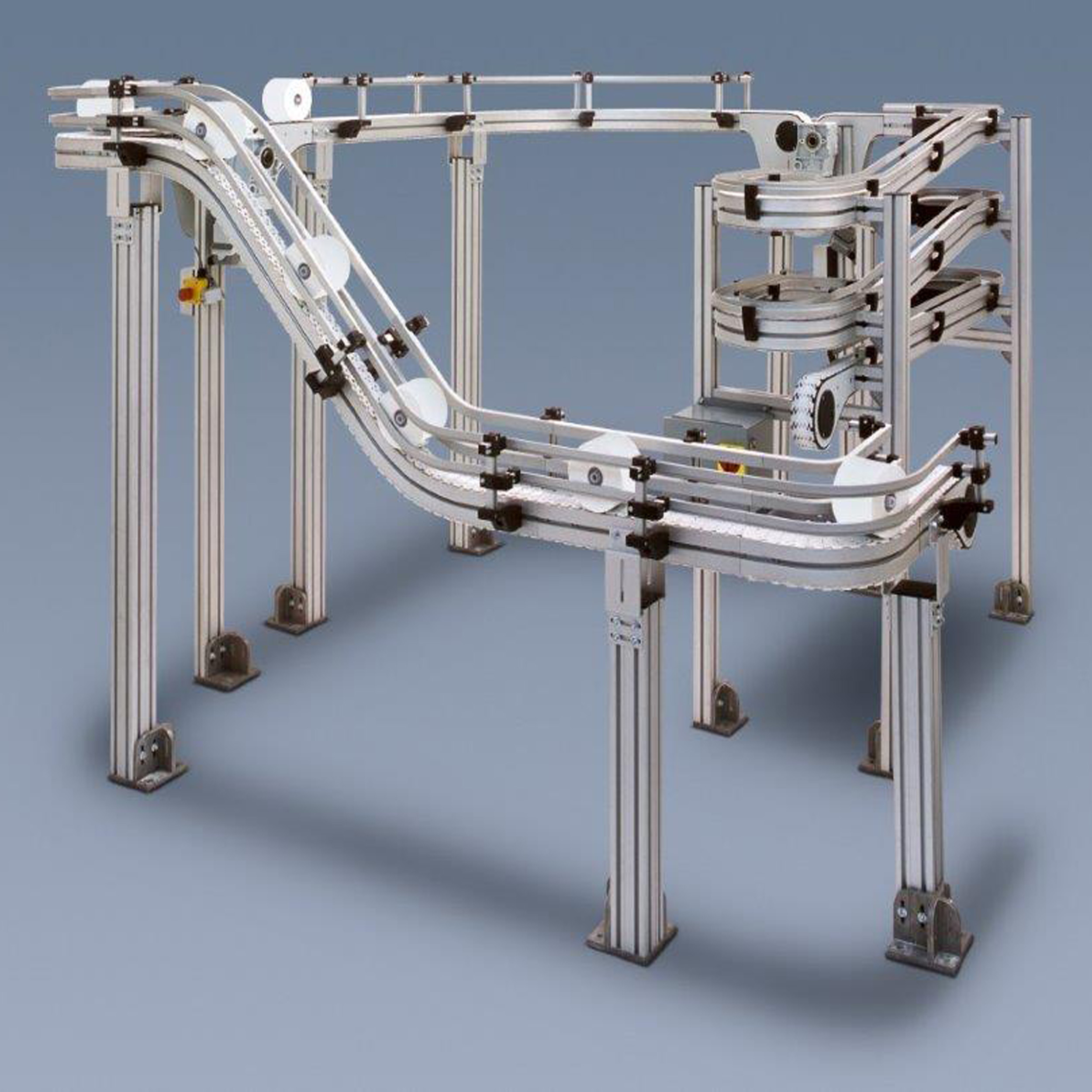

Continuous Flow Conveyor Systems

Rexroth chain conveyors optimize material handling with flexible designs, MTpro software, and 3D CAD for efficient, customizable production lines.

Explore our Rexroth Options

Automated Testing

Automated testing solutions improve quality, efficiency, and ergonomics with precise data capture, reducing errors and boosting productivity.

Mechanized Systems

Custom mechanized systems designed to automate manufacturing, cut labor costs, boost efficiency, and improve accuracy for optimized production.

Watch our Automated Systems in Action on YouTube

Control Automation

Expert controls engineers deliver integrated automation systems, uniting mechanical, electrical, and process components for seamless performance.

Robotic Systems Integration

Collaborative robots boost productivity and safety, reducing stress while meeting ANSI/RIA R15.06-2012 standards with built-in guarding and risk assessments.

Find the Right Robotic Solutions