Mechanical Automation Systems

Pneumatic-Hydraulic Tilt Tables

Pneumatic-hydraulic tilt tables with T-slot frames improve ergonomics, reduce lifting strain, and boost safety and productivity in manufacturing.

Automated Assembly Machines

Automated assembly machines and custom presses boost efficiency, accuracy, and safety while improving quality and productivity in high-volume manufacturing.

Modular Paint & Powder Spray Booths

Custom modular paint and powder spray booths ensure safe, efficient coating with explosion-proof lights, ventilation, and controlled environments.

Automated Parts Shuttle

Automated parts shuttles with rodless cylinders and guide rails streamline material handling, boost efficiency, and support CNC and warehouse use.

Automated Drilling Machine

Automated drilling machines with magazine loading and multi-head precision boost speed, accuracy, and efficiency in high-volume manufacturing.

Small Part Assembly Press

Small part assembly presses improve safety, ergonomics, and quality, delivering precise, consistent results to optimize workflows in manufacturing.

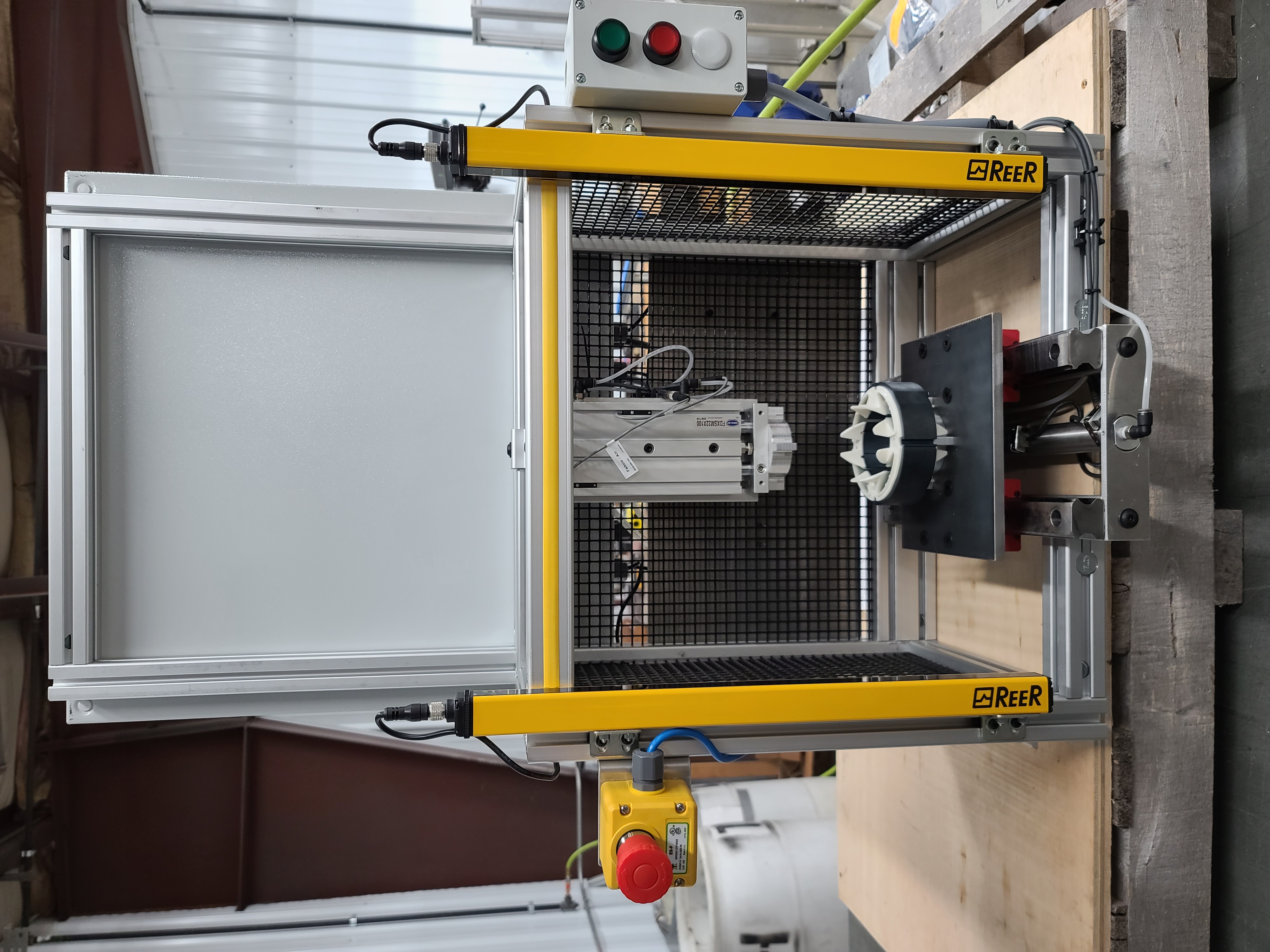

Precision Small Part Assembly Press

Precision small part assembly press offers modular, space-saving automation with 120V plug-in power and optional electric actuators for efficiency.

Automated Axle Cleaning System

Automated axle cleaning systems for the rail industry boost efficiency, reduce downtime, and deliver reliable locomotive maintenance with precision.

Nozzle Leak Test Machine

Nozzle leak test machines ensure fire hose reliability by testing up to 300 psi, verifying quality and performance for critical emergency use.