Robotic System Integration

Collaborative and Cartesian Robotics

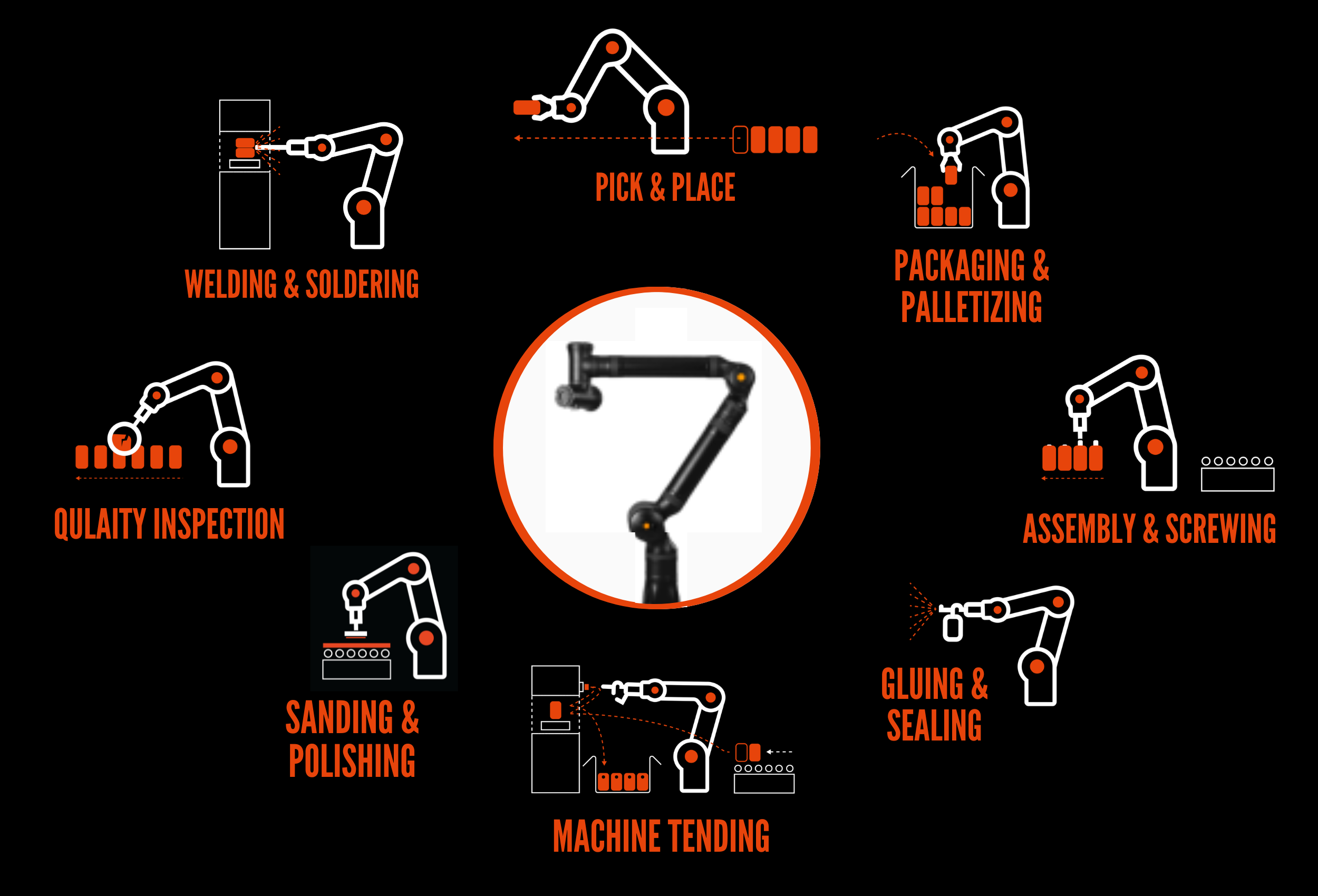

Authorized Systems Integrator delivering cobot solutions to reduce fatigue, boost safety, and improve productivity in ergonomic manufacturing environments.

JAKA 6-axis Collaborative Robot

6-axis collaborative robot with 40kg payload and 1300mm reach boosts safety, precision, and productivity in assembly, packaging, and material handling.

To learn more about the JAKA Cobot brand

Robotics Perimeter Guarding

Ensure safe robotic system integration with advanced perimeter guarding solutions that protect personnel, boost productivity, and comply with industrial safety standards.

Bosch-Rexroth

Cartesian Robotic Systems

Cartesian robotic systems with multi-axis servo control and modular T-slot design boost efficiency, scalability, and flexibility in manufacturing.

Check out the positioning and handling tasks By Rexroth

Features and Benefits

- Ideal for Lighter, Repetitive Tasks: Perfect for repetitive operations, improving overall efficiency.

- Improved Workplace Safety: Designed with built-in safety features to ensure a secure working environment.

- Enhanced Quality: Consistent precision enhances product quality with minimal errors.

- User-Friendly Operation: Easy to use, focusing on collaborative robot safety for seamless human interaction.

- Cost-Effective: More affordable compared to traditional industrial robots, offering high value.

- Increased Precision & Productivity: Boosts accuracy while enhancing overall production speed.

- Flexible Placement & Programming: Easily adaptable to various configurations and production needs.

- Adaptable to EOAT (End-of-Arm-Tooling): Customizable for diverse tasks and requirements.

- Safety-Focused Design: No sharp edges or pinch points to ensure operator safety.

- Reliable During Power Outages: Holds gripper pressure to maintain control during power failures.

- Cobot Risk Assessment Consulting: Available to help ensure compliance and safety.

- Mobility: Create quick turn operational needs to meet Kaizen / Lean Manufacturing needs or to simplify setup requirements with a standard self-tech robotics package.

Get Started Automating Your Processes Today with Robotics