Part Fixturing and Tooling

Forming Fixtures

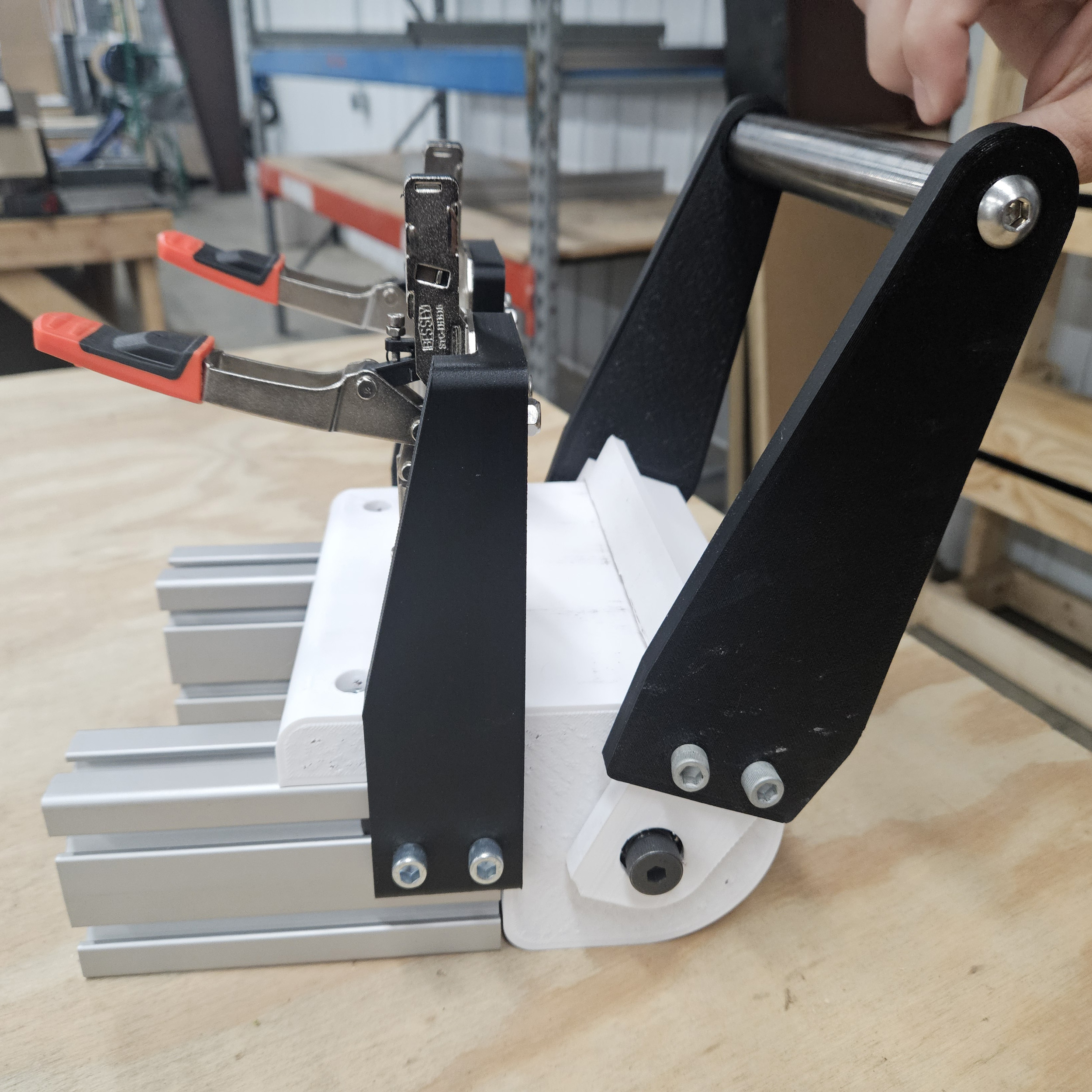

Forming fixtures with T-slot extrusion and 3D printed parts provide consistent product quality through flexible, cost-effective prototyping solutions for adaptable manufacturing needs.

No-Touch Tools

No-touch safety tools like pushers, rakes, and levers integrate with machine guarding to reduce risk, prevent injuries, and protect workers.

3D Printing Manufacturing

Advanced 3D printing with filament and resin enhances fixtures, boosts quality, and streamlines production with flexible, cost-effective solutions.

Automated Testing and Part Fixturing

Test fixtures providing benefits by semi-automating quality checks with precision technology, reducing errors, improving ergonomics, and boosting efficiency in production.