Machine Safety Assessment Services

Whether you're managing legacy equipment or trying to keep pace with evolving safety standards, knowing where you stand is the first step toward meaningful risk reduction.

Our Machine Safety Assessment Services are designed to improve compliance, protect your people, and support smarter investment decisions.

Schedule Your Safety Assessment

Guarding Assessments

Our team visits your facility to assess your current machine guarding and identify safety risks. We partner with your operators to identify hazards and design custom safety solutions that reduce risk without disrupting productivity.

Learn more the Guarding Assessment process →

Machine Stop-Time & Safety Distance Verification

Ensure your machine safety devices are installed at the proper distance based on real stopping performance.

We plan an onsite visit to measure deceleration time, calculate minimum safe approach distance, and confirms compliance with relevant standards to protect workers and prevent bypass risk.

Learn more about the Machine Stop-Time & Safety Distance process →

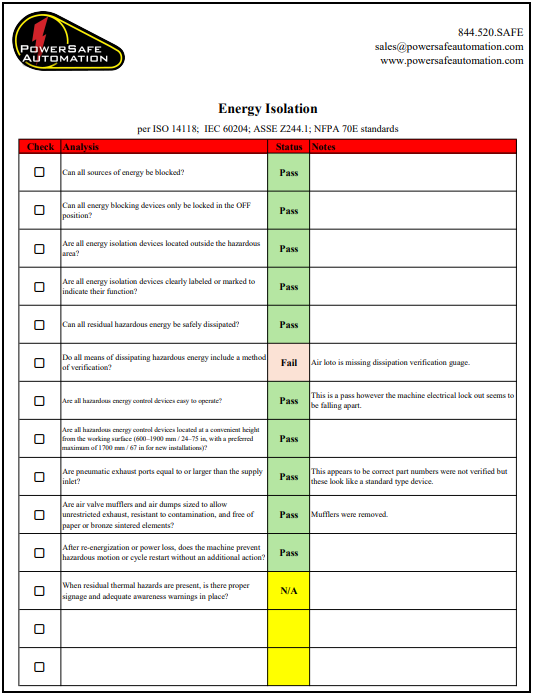

Machine Safety Validation

Ensure your existing machine guarding and safety systems are performing exactly as intended.

Our Machine Safety Validation Service confirms that safety devices, controls, and stop-time distances meet regulatory requirements and function reliably under real-world operating conditions. Get documentation with a verified safety baseline that you can reference for future audits, compliance, and risk-reduction planning.

Learn more about our Machine Safety Validation process →

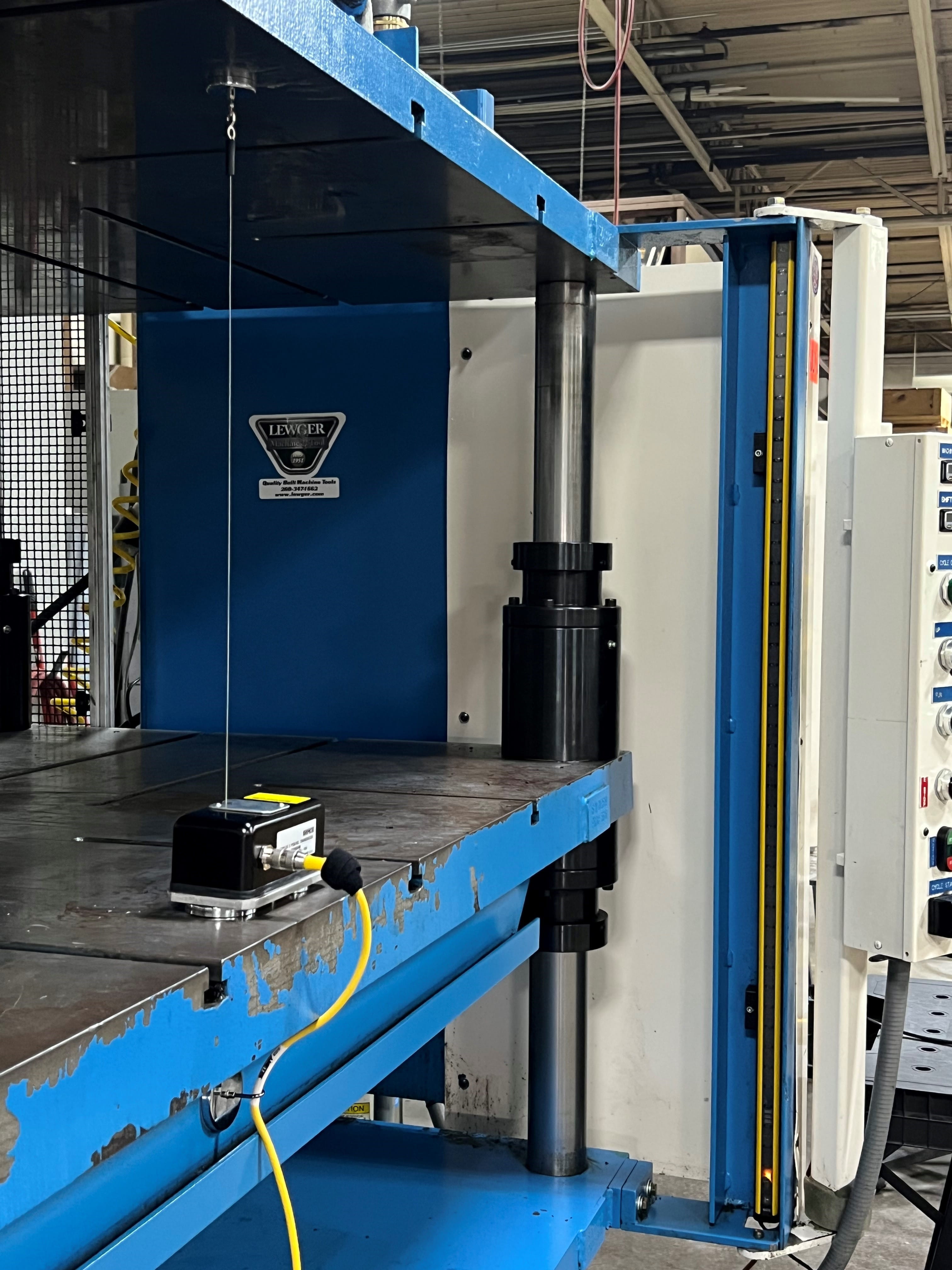

Pre-Purchase Machine Guarding Assessment

Make an informed buying decision before equipment arrives onsite.

We evaluate new or used machinery for compliance risks, missing safety devices, hidden retrofit costs, and required guarding upgrades. This proactive review helps you budget accurately, avoid unexpected downtime, and ensure your investment aligns with risk reduction safety expectations from day one.

Learn about our Pre-Purchase Machine Guarding Assessment →

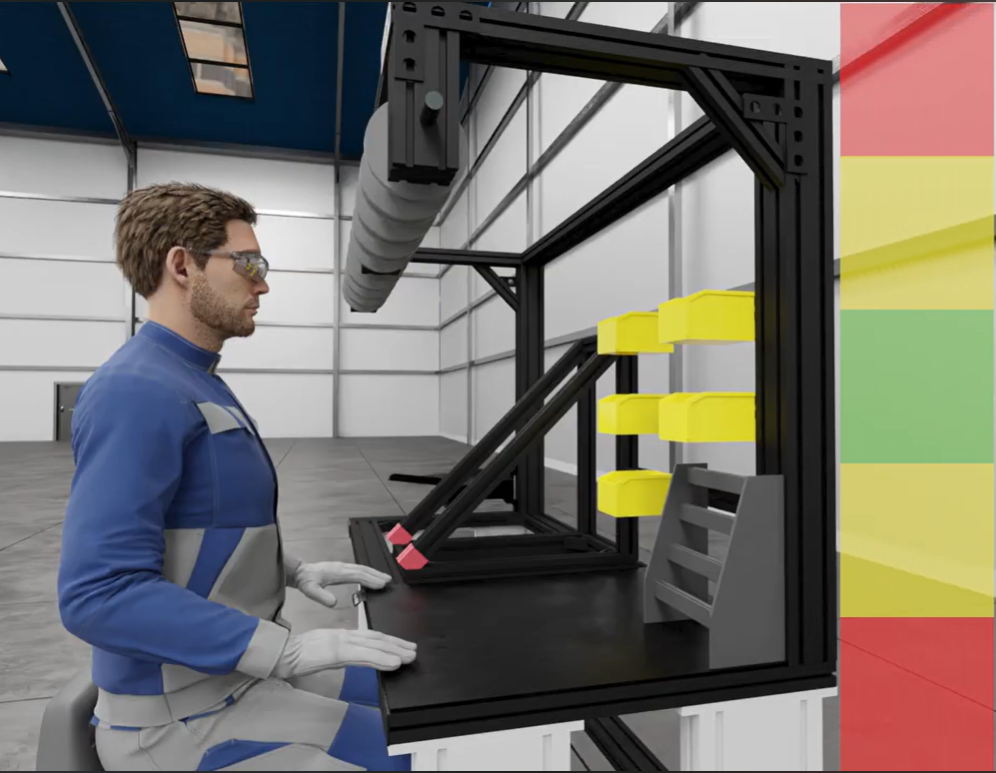

Green-Zone Ergonomic Workstation Assessment

Optimize everyday, lower-risk high-volume production tasks with a focused ergonomic review.

We walk your team through a structured review of work-height, reach zones, posture, tools, task layout and material flow to identify areas where simple adjustments or workstation upgrades deliver big wins.

Learn about our Green-Zone Ergonomic Workstation Assessment →

Risk Reduction Prioritization Program

Objective machine risk scoring that clearly prioritizes safety upgrades and investments.

During our on-site evaluation, we assess each machine using a practical scoring system based on four key factors:

- How much exposure workers have to hazards

- How serious potential injuries could be

- How often the hazard occurs

- How easily people can access dangerous areas

You'll get a prioritized action plan with photos and specific recommendations giving you a clear roadmap to reduce risk and plan upgrades over time.

Learn about our Risk Reduction Prioritization Program →

Get the Assessment You Need

Machine safety doesn't have to be reactive. With the right assessment, you get the insight needed to prevent incidents before they happen.

Schedule your assessment and build a safer work environment for your team.

Schedule Your Safety Assessment