T-Slotted Extrusion Framing

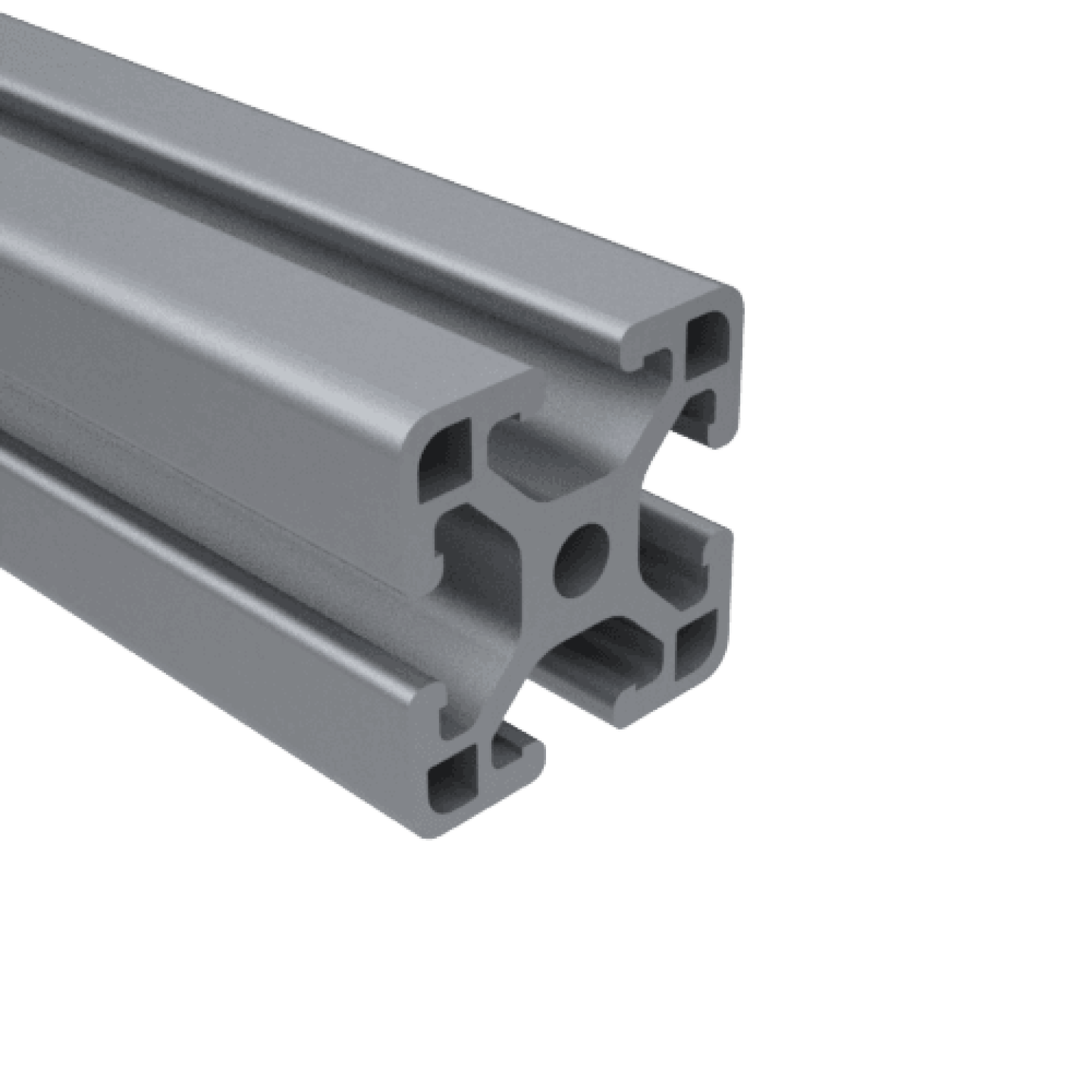

T-Slotted Extrusion Profiles

Modular, structural framing, used for machine safety guarding and modular system builds.

High-strength aluminum profile enables fast, modular machine-safety and automation frameworks with minimal machining.

T-slotted extrusion profiles are modular, aluminum framing components engineered for building machine guards, workstations, enclosures, carts, and custom industrial structures. Featuring precision-machined T-slots along each side, these extrusions allow fast, bolt-together assembly without welding—making them ideal for flexible manufacturing environments. Lightweight yet strong, T-slot aluminum profiles provide excellent corrosion resistance, easy reconfiguration, and compatibility with a wide range of brackets, fasteners, panels, and accessories. Commonly used for machine safety guarding, automation cells, and lean manufacturing solutions, T-slotted extrusion systems help manufacturers build durable, clean, and cost-effective structures that can be modified or expanded as operations evolve.

User-Friendly Design

- Modular “T”-slot groove lets users slide connectors and hardware without welding.

- Anodized aluminum finish resists corrosion and maintains clean industrial look.

- Available in fractional (10 series, 15 series) and metric (30 series, 40 series, 45 series) sizes for compatibility.

Flexible Mounting Options

- Works with end-fasteners, angle brackets, “drop-in” T-nuts, and pivot connectors for various joints.

- Can be cut to length, drilled, tapped, or used “as-is” depending on build-needs.

- Compatible with other manufacturers’ extrusions (100% compatible claim) so retrofit and expansion is easy.

Seamless System Integration

- Integrates with accessory brackets, fasteners, panels, casters, and guarding components for turnkey systems.

- Ideal backbone for machine-safety enclosures, workstation frames, conveyor supports, and guarding systems.

- Lightweight aluminum means less structural load and easier installation compared to steel-welded frames.

T-Slotted Extrusion Profiles

Modular, structural framing, used for machine safety guarding and modular system builds.

High-strength aluminum profile enables fast, modular machine-safety and automation frameworks with minimal machining.

T-slotted extrusion profiles are modular, aluminum framing components engineered for building machine guards, workstations, enclosures, carts, and custom industrial structures. Featuring precision-machined T-slots along each side, these extrusions allow fast, bolt-together assembly without welding—making them ideal for flexible manufacturing environments. Lightweight yet strong, T-slot aluminum profiles provide excellent corrosion resistance, easy reconfiguration, and compatibility with a wide range of brackets, fasteners, panels, and accessories. Commonly used for machine safety guarding, automation cells, and lean manufacturing solutions, T-slotted extrusion systems help manufacturers build durable, clean, and cost-effective structures that can be modified or expanded as operations evolve.

User-Friendly Design

- Modular “T”-slot groove lets users slide connectors and hardware without welding.

- Anodized aluminum finish resists corrosion and maintains clean industrial look.

- Available in fractional (10 series, 15 series) and metric (30 series, 40 series, 45 series) sizes for compatibility.

Flexible Mounting Options

- Works with end-fasteners, angle brackets, “drop-in” T-nuts, and pivot connectors for various joints.

- Can be cut to length, drilled, tapped, or used “as-is” depending on build-needs.

- Compatible with other manufacturers’ extrusions (100% compatible claim) so retrofit and expansion is easy.

Seamless System Integration

- Integrates with accessory brackets, fasteners, panels, casters, and guarding components for turnkey systems.

- Ideal backbone for machine-safety enclosures, workstation frames, conveyor supports, and guarding systems.

- Lightweight aluminum means less structural load and easier installation compared to steel-welded frames.

- Assembly consists of:

- Extruded aluminum profile cut to length

- Optional mounting brackets and T-nut fasteners

- Installation guide and spec sheet for loading, machining and deflection.

- Note: panels, interlock systems, sensors, and hardware may be separately ordered.

- Common uses include:

- Machine guarding frames around CNC machines, punch presses, lasers, and robotics.

- Workstations, mobile carts, shelves, material handling frames, mezzanines or platforms.

- Retro-fits and expansions in manufacturing facilities where flexibility matters.