Presence Sensing Safety Devices

Safety Switch Mats

Durable floor-mounted presence-detection for machine guarding and operator safety.

Molded safety mat detects operator presence, resists oil and debris, integrates easily with safety control systems.

Safety switch mats are pressure-sensitive safety devices designed to detect the presence of personnel in hazardous machine zones. When a person steps onto the mat, the system instantly triggers a stop signal—halting machine motion to prevent injury. Built for rugged industrial environments, Recora safety mats offer durable, non-slip surfaces, customizable sizes, and reliable perimeter or area guarding for presses, robots, conveyors, and automated equipment. With fast response times and compliance with OSHA, ANSI, and ISO safety standards, Recora mats provide a simple, effective way to create safe approach zones and protect workers during operation, setup, and maintenance.

User-Friendly Design

- Fully molded surface with ramped edges and rugged vinyl construction for durability in industrial environments.

- Low profile (approx. 3/8" thickness in many series) for minimal trip hazard and easy integration in walk-zones.

- Standard lead wires and straightforward wiring (often two-wire normally-open switch) for simple connection to safety relays or controllers.

Flexible Mounting Options

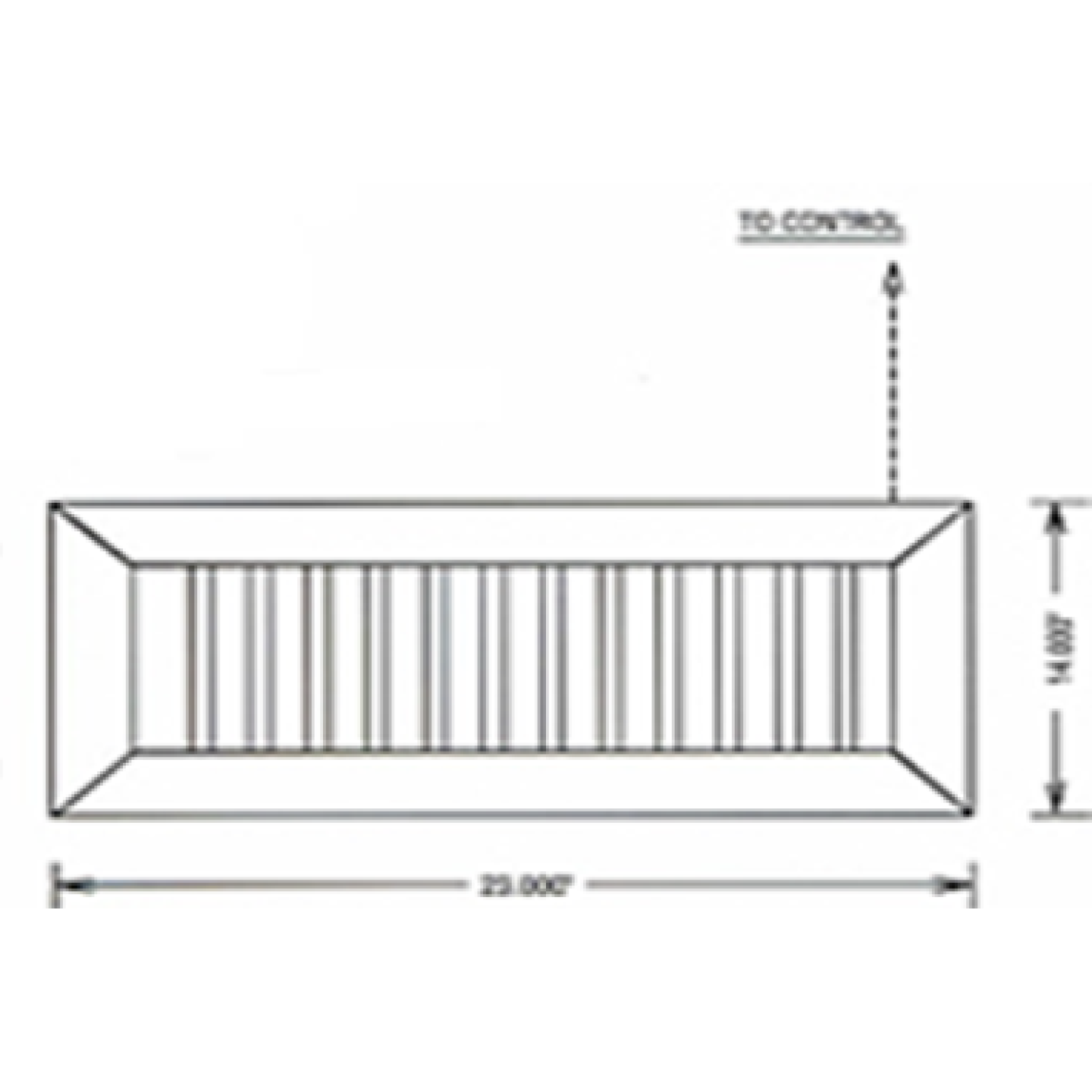

- Available in various sizes and series (e.g., 12H, 14H, 15H, 30H) to match different floor footprint needs.

- Can be placed in front of machines, at guard doors, on conveyor access zones, or any presence-sensing floor area due to its thin profile.

- Rugged design tolerates dirty, oily, or welded-spatter environments, making it suitable for industrial manufacturing floors.

Seamless System Integration

- Compatible with safety control logic: used as presence-sensing device triggering safety stop or change of mode when activated.

- Fail-safe versions available (e.g., HD series with dual leads) that support higher-integrity safety circuits.

Safety Switch Mats

Durable floor-mounted presence-detection for machine guarding and operator safety.

Molded safety mat detects operator presence, resists oil and debris, integrates easily with safety control systems.

Safety switch mats are pressure-sensitive safety devices designed to detect the presence of personnel in hazardous machine zones. When a person steps onto the mat, the system instantly triggers a stop signal—halting machine motion to prevent injury. Built for rugged industrial environments, Recora safety mats offer durable, non-slip surfaces, customizable sizes, and reliable perimeter or area guarding for presses, robots, conveyors, and automated equipment. With fast response times and compliance with OSHA, ANSI, and ISO safety standards, Recora mats provide a simple, effective way to create safe approach zones and protect workers during operation, setup, and maintenance.

User-Friendly Design

- Fully molded surface with ramped edges and rugged vinyl construction for durability in industrial environments.

- Low profile (approx. 3/8" thickness in many series) for minimal trip hazard and easy integration in walk-zones.

- Standard lead wires and straightforward wiring (often two-wire normally-open switch) for simple connection to safety relays or controllers.

Flexible Mounting Options

- Available in various sizes and series (e.g., 12H, 14H, 15H, 30H) to match different floor footprint needs.

- Can be placed in front of machines, at guard doors, on conveyor access zones, or any presence-sensing floor area due to its thin profile.

- Rugged design tolerates dirty, oily, or welded-spatter environments, making it suitable for industrial manufacturing floors.

Seamless System Integration

- Compatible with safety control logic: used as presence-sensing device triggering safety stop or change of mode when activated.

- Fail-safe versions available (e.g., HD series with dual leads) that support higher-integrity safety circuits.

- Assembly consists of:

- Recora Switchmat main unit (heavy-duty molded safety presence mat).

- Lead wire(s) for connection to control/safety system (typical: 2-wire, normally open; HD versions may include 4 wires).

- Mounting instructions/documentation sheet (installation and wiring details).

- Ramp edging molded into many mats or optional edging kit (depending on model).

- Note: Safety relay, PLC safety module or machine-controller are not included — these must be supplied separately or integrated via your turnkey solution.

- Common uses include:

- Floor-mounted presence detection in robot cells: detect operator entry into hazardous zones and trigger machine stop or safe state.

- Gate/door area mat: mount just inside or outside guard door to monitor foot-traffic before unlocking or allowing access.

- Conveyor pass-through mats: placed at entry/exit points where an operator might access or retrieve parts, providing cost-effective detection when overhead scanners or light curtains aren’t ideal.

- Harsh environment access: ideal for wash-down, oil/lubricant spill zones, or dusty manufacturing zones where optical sensors may fail but a pressure-sensitive mat still functions reliably.

- Troubleshooting Tips:

- Confirm correct installation of the mat: the mat should lie flat on a stable surface with no folds/curls and be properly sized for the protected zone. According to Recora documentation: “flat mounting, correct edge sealing, and no interference” are key.

- Verify wiring and control-circuit integration: check that the safety mat’s outputs (e.g., switch-mat output, zone controllers) are wired correctly into your safety-PLC/relay system, with proper diagnostic monitoring where required.

- Inspect for physical damage or contamination: heavy wear, oil/coolant spills, weld spatter or debris lodged under the mat can lead to false trips or failure to detect. Recora highlights the heavy-duty mats are resistant to industrial liquids but still require routine cleaning.

- Check for correct sensing behavior: The mat should reliably detect presence across its surface (no blind spots). For multi-zone mats or larger layouts, validate that each zone is reacting appropriately when stepped on/tested.

- Confirm mechanical fixation and edge termination: If the mat’s edges are frayed, the cover is lifting, or fasteners have loosened, the detection characteristics may change. Maintenance schedule should include inspection of mounting and edges.

- Evaluate electrical integrity and fail-safe functionality: Recora mats are designed for fail-safe operation even through severed leads or power failure. Yet you should periodically test these fail-safe conditions (simulate lead fault, power interruption) to confirm system behavior.

- Monitor for repeated fault or trip events: A pattern of repeated false activations or “no activation” incidents may indicate root causes such as mechanical wear, contamination build-up, wiring loosening, or installation of wrong zone size. Log events, review trends

- Ensure correct zone sizing and layout: The protective zone defined by the mat must match your risk assessment criteria (object/foot size, machine stop time, hazard zone geometry). If the mat is too small or placed in an inappropriate location, it may not provide full protection.

- Perform functional testing after installation or maintenance: Walk/test across the full mat area, verify the machine enters the safe state when the mat is loaded, remove load and verify the machine resumes operation only when safe. Document the results.

- Schedule routine maintenance: At set intervals (quarterly/semi-annually depending on usage) inspect mat surface for wear, clean the mat, check connectors and wiring for corrosion or loosening, verify mounting is still secure, verify correct output behavior.

- Verify environmental suitability: Ensure that the mat is rated for the environment it’s used in. For example, if there are forklift or heavy cart traffic, select a heavy-duty mat designed for vehicle passage. Recora’s heavy-duty series explicitly highlight vehicular protection.

- Confirm any auxiliary functions (e.g., zone controllers, stand-alone presence detection mats) are configured correctly and their status indicators (LEDs) are reviewed for fault/warn states.

- Keep documentation accessible: Store the installation manual, wiring diagrams, test logs, and maintenance records for the mat system — helps in audits, risk assessments, and troubleshooting future issues.