Presence Sensing Safety Devices

Safety Light Curtains

High-performance safety light curtain, precision detection, flexible mounting, simple integration.

Slim, durable safety light curtain detects intrusion in hazardous zones, ideal for machine guard openings and high-throughput cells.

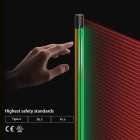

Safety light curtains are photoelectric presence-sensing devices designed to protect operators from moving machine hazards by creating an invisible infrared barrier around dangerous areas. When any beam is interrupted—such as when a hand or body enters the zone—the system instantly sends a stop signal to halt machine motion. Widely used on presses, robots, packaging lines, and automated machinery, safety light curtains provide fast response times, flexible mounting options, and various resolutions for finger, hand, or full-body detection. Compliant with OSHA, ANSI, and ISO standards, they offer a reliable, maintenance-friendly solution for safeguarding access points without the need for physical gates or guards.

User-Friendly Design

- Full-length status indicators make alignment and diagnostics faster — users can see at a glance if beam-axis misalignment or sensor contamination exists.

- Slim housing designs (e.g., GL-S Series) fit tight guard openings and minimize profile, enabling easier retrofit.

- Built-in alignment assistance, simplified wiring connectors (M12 etc) reduce installation time and cost.

Flexible Mounting Options

- Series like GL-R support long sensing ranges (up to ~15 m) and heavy-duty industrial environments.

- Wide selection of mounting brackets, adjustable orientations, and cascade options make adaptation to different guard openings or machine configurations easier.

- Available in multiple resolution types (14 mm, 25 mm, 45 mm) to match required protection zones (finger, hand, body).

Seamless System Integration

- Certified to Type 4, Category 4/PL e (depending on configuration), SIL3 capable, self-diagnosing devices built for high-integrity safety applications.

- Easily wires into your safety circuit (OSS outputs, muting/blanking functions, optional safety relay kits) to work with your machine-controller or safety-PLC.

- Compatible with typical industrial environments—high IP ratings (IP65/67) protect against oil, dust and vibration.

Safety Light Curtains

High-performance safety light curtain, precision detection, flexible mounting, simple integration.

Slim, durable safety light curtain detects intrusion in hazardous zones, ideal for machine guard openings and high-throughput cells.

Safety light curtains are photoelectric presence-sensing devices designed to protect operators from moving machine hazards by creating an invisible infrared barrier around dangerous areas. When any beam is interrupted—such as when a hand or body enters the zone—the system instantly sends a stop signal to halt machine motion. Widely used on presses, robots, packaging lines, and automated machinery, safety light curtains provide fast response times, flexible mounting options, and various resolutions for finger, hand, or full-body detection. Compliant with OSHA, ANSI, and ISO standards, they offer a reliable, maintenance-friendly solution for safeguarding access points without the need for physical gates or guards.

User-Friendly Design

- Full-length status indicators make alignment and diagnostics faster — users can see at a glance if beam-axis misalignment or sensor contamination exists.

- Slim housing designs (e.g., GL-S Series) fit tight guard openings and minimize profile, enabling easier retrofit.

- Built-in alignment assistance, simplified wiring connectors (M12 etc) reduce installation time and cost.

Flexible Mounting Options

- Series like GL-R support long sensing ranges (up to ~15 m) and heavy-duty industrial environments.

- Wide selection of mounting brackets, adjustable orientations, and cascade options make adaptation to different guard openings or machine configurations easier.

- Available in multiple resolution types (14 mm, 25 mm, 45 mm) to match required protection zones (finger, hand, body).

Seamless System Integration

- Certified to Type 4, Category 4/PL e (depending on configuration), SIL3 capable, self-diagnosing devices built for high-integrity safety applications.

- Easily wires into your safety circuit (OSS outputs, muting/blanking functions, optional safety relay kits) to work with your machine-controller or safety-PLC.

- Compatible with typical industrial environments—high IP ratings (IP65/67) protect against oil, dust and vibration.

- Assembly consists of:

- Transmitter and receiver modules of the light curtain pair (e.g., SL-V or GL series).

- Mounting brackets and hardware (standard adjustable brackets) suitable for vertical installation around guard opening.

- Quick-reference installation guide with alignment instructions, wiring diagram for safety outputs and recommended clearances.

- Note: Safety relay, machine safety controller, and door/guard interlock switches are not included but will be required for full system compliance.

- Common uses include:

- Guarding access openings on CNC machines, press brakes, robotic cells where minimal physical barriers and quick access are required.

- High-speed applications where operators need proximity and high throughput but still require robust safeguarding.

- Retrofit projects upgrading legacy or unguarded machines to meet current safety standards (ISO 13849, ANSI, OSHA).

- Zones where space is limited and guard door access must remain unobstructed but safety intrusion detection is required.

- Troubleshooting Tips:

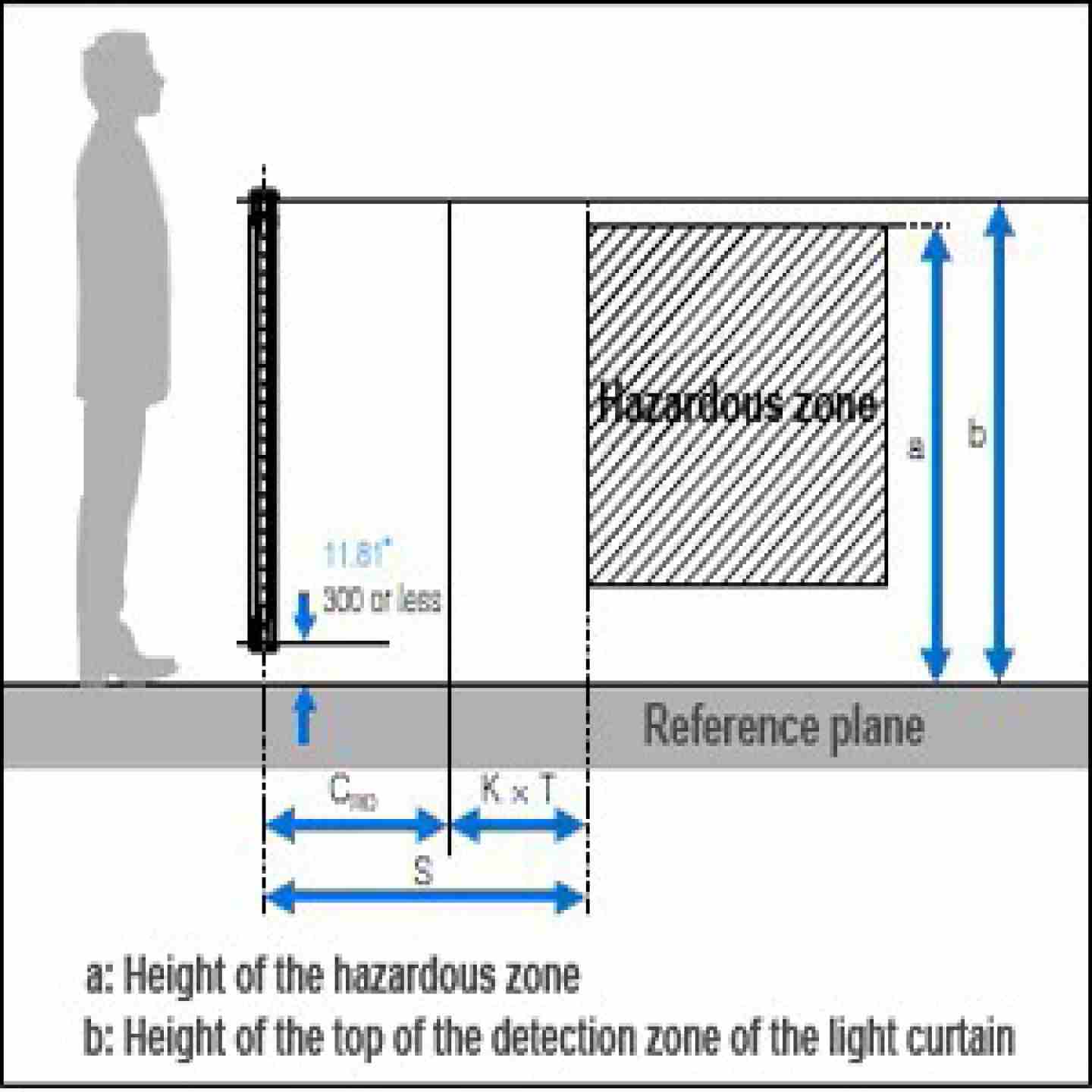

- Confirm the light curtain is mounted at the correct distance from the hazardous zone. The minimum safety distance must comply with the device’s specified response time and beam spacing.

- Verify that the transmitter and receiver beam axes are properly aligned. Misalignment is one of the most common causes of fault/trip conditions.

- Inspect full-length status indicators on the unit. On the GL-V/GL-R series, full-length LED indicators help identify miswiring, beam misalignment, or blocked beams.

- Check for environmental interference: unusual lighting (like direct sunlight, inverter-type fluorescent lamps), reflective surfaces, or heavy contamination (oil, coolant, dust) can impair detection.

- Ensure the power supply is correct (24 V DC typically) and stable. Voltage drops or improper supply conditions may lead to system error states.

- Confirm wiring of the required safety outputs (usually dual OSSD outputs) into the safety control circuit. Using only one output or wiring incorrectly may compromise the safety integrity.

- Review the use of fixed blanking or muting functions (if applied). These allow intended items to pass the beam but reduce protection zones—ensure they’re correctly applied and that any resultant clearance is safeguarded per risk assessment.

- Examine cascading connections (series connection of multiple curtains). If one unit in the series fails, it can affect the whole system – verify communication/wiring between units.

- Cleaning & maintenance: Wipe lenses/optical surfaces clean, ensure mounting brackets remain rigid, and verify no mechanical drift or loosened fasteners. Routine inspection prevents nuisance trips.

- After installation or maintenance, perform a full function test: with the light curtain energized, test the protective zone by using a test piece (diameter according to the curtain type: finger/hand/body) and verify machine stops as expected.