Presence Sensing Safety Devices

RFID Safety Interlock Switches (locking)

Robust, power-to-lock or power-to-unlock guard locking switch for modern machine guarding

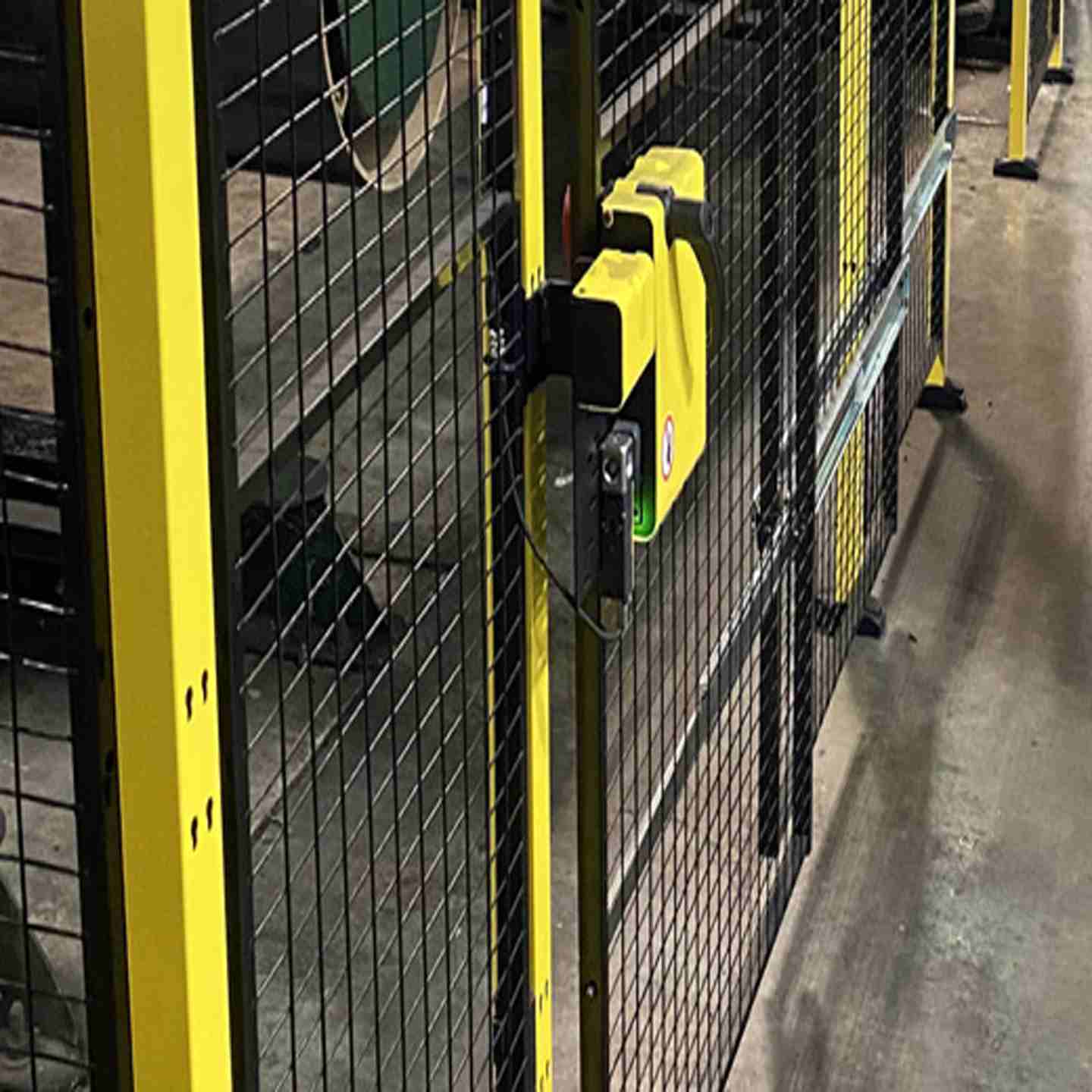

Used to secure machine access doors until a verified safe condition is met, allowing controlled entry.

Safety interlock switches ensure machines stop when guards open and remain secured until safe. The Keyence GS Series offers power-to-release and power-to-lock models with compact, rugged construction and IP65/67/69K ratings for harsh environments. Designed for high-performance safety without slowing workflow, these switches are ideal for securing access points in modern automated and industrial applications..

User-Friendly Design

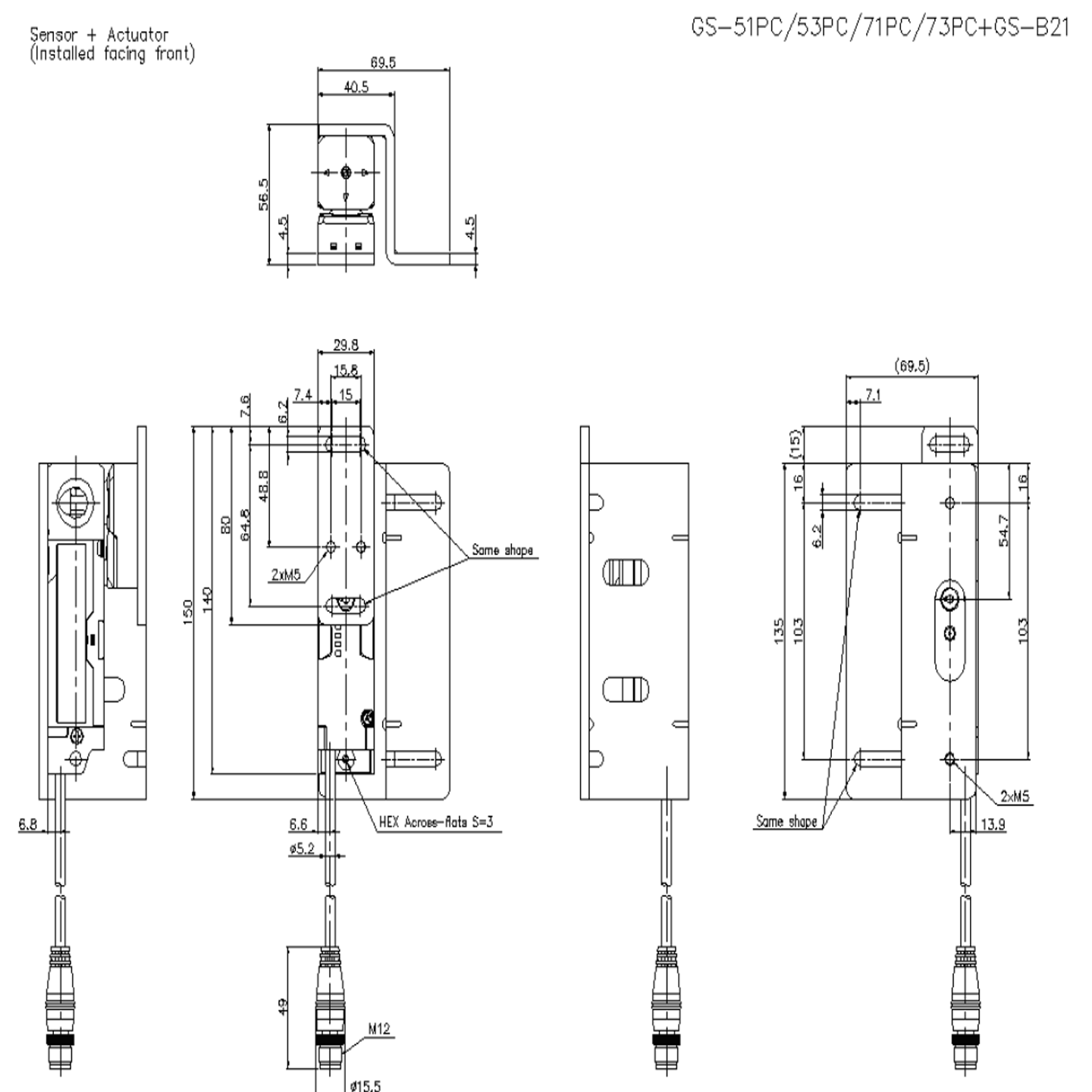

- Compact footprint fits tight or complex installation spaces

- Durable, industrial-grade construction for long-term reliability

- Bright visual status indicators for fast, at-a-glance safety confirmation

Flexible Mounting Options

- Available in locking or non-contact configurations to match application needs

- Mount directly to equipment or with purpose-built brackets

- Engineered to prevent false trips from vibration, misalignment, or door sag

Seamless System Integration

- Includes auxiliary output for added monitoring and functionality

- Cascade wiring reduces cable clutter and simplifies installation

- Built-in OSSD compatibility supports EDM and manual reset for modern safety systems

RFID Safety Interlock Switches (locking)

Robust, power-to-lock or power-to-unlock guard locking switch for modern machine guarding

Used to secure machine access doors until a verified safe condition is met, allowing controlled entry.

Safety interlock switches ensure machines stop when guards open and remain secured until safe. The Keyence GS Series offers power-to-release and power-to-lock models with compact, rugged construction and IP65/67/69K ratings for harsh environments. Designed for high-performance safety without slowing workflow, these switches are ideal for securing access points in modern automated and industrial applications..

User-Friendly Design

- Compact footprint fits tight or complex installation spaces

- Durable, industrial-grade construction for long-term reliability

- Bright visual status indicators for fast, at-a-glance safety confirmation

Flexible Mounting Options

- Available in locking or non-contact configurations to match application needs

- Mount directly to equipment or with purpose-built brackets

- Engineered to prevent false trips from vibration, misalignment, or door sag

Seamless System Integration

- Includes auxiliary output for added monitoring and functionality

- Cascade wiring reduces cable clutter and simplifies installation

- Built-in OSSD compatibility supports EDM and manual reset for modern safety systems

- Assembly consists of:

- Safety interlock switch, activator key, M12 x 8-pin at 20m cable, mounting brackets

- Safety relay or safety controller sold separately

- Common uses include:

- Perfect for machine guarding at operator access points including doors, gates, and removable covers.

- Presses, CNC machines, robotic cells, conveyor hatches, packaging lines, assembly stations, mixers, blending equipment, and other automated or high-risk machinery.

- Troubleshooting Tips:

- Verify that the guard door or access point is correctly aligned with the actuator. Misalignment (door sag, mis-hinging, or worn hinge) is one of the most common causes of the interlock failing to register “closed” or “locked”.

- Check the power supply to the locking device: ensure the correct voltage and that power-to-lock or power-to-release configuration is consistent with the model specification. Without proper power, the lock mechanism may not engage or disengage as required.

- Inspect the status indicator lights. Many modern switches (such as the KEYENCE GS series) provide visual signals for “closed”, “open”, “locked”, “error”. Using these lights helps quickly pinpoint if the switch is sensing correctly.

- Confirm the auxiliary output wiring and monitoring circuits. If the auxiliary output is used to signal to a PLC or HMI, ensure wiring continuity, correct terminal connections, and that the signal is recognized by the control system.

- Scroll through cascading connections (if used). If multiple interlock switches are cascaded, one unit mis‐wired or misconfigured can affect the entire line; check each unit in the cascade for correct function and wiring.

- Evaluate environmental conditions: These devices are rated for IP65/67/69K in many cases, but heavy contamination, metal shavings, coolant spray or extreme vibration may degrade performance. Clean the switch head/actuator mating surfaces and ensure no debris is interfering with actuation.

- Test the manual/escape release feature (if present). For equipment requiring safe egress or maintenance access, the manual release must operate reliably and the lock must yield under its conditions—test it periodically.

- Check the safety performance rating and proper category compliance. Confirm the switch meets required performance levels (for example PLe / Category 4 / SIL3) for your machine safety risk assessment.

- Verify actuator coding (if available). Some models allow actuator coding or pairing to prevent tampering or substitution—ensure the correct actuator is used and is uniquely paired if required.

- Perform a full function test after installation or maintenance: Open the guard, verify the machine stops, close the guard, verify the lock engages (if power-to-lock) or remains locked (if power-to-release) and the machine can only restart when the condition is safe.

- Document and log faults/trips. Maintain a log of each fault event (date, indicator status, circumstances). Over time, patterns (such as frequent false trips, door vibration, repeated lock failure) will point to root causes (e.g., hinge wear, sequence error, wiring degradation).

- Keep firmware/configuration current (if applicable). Some advanced models may have firmware or configuration updates—check with the manufacturer and update if needed to ensure optimal performance and diagnostic capability.

- Engage maintenance schedule: At intervals (e.g., quarterly), inspect mechanical parts (hinges, bolts, actuator engagement surfaces), verify torque of mounting hardware, and verify that the lock/unlock mechanism has not drifted or worn.

- Use diagnostic outputs where available. Modern interlock switches often have additional outputs for condition monitoring (e.g., AUX output) — connect these to your machine’s diagnostic system so you can detect a near-fault (e.g., misalignment warning) before a full stop occurs.

- Ensure correct selection for application: If the machine has residual motion after power off (large inertia), a power-to-release type (remains locked with no power) may be required; if the hazard is eliminated on power off instantly, the power-to-lock type may be appropriate. Use your risk assessment to verify.