Power Transmission Guards

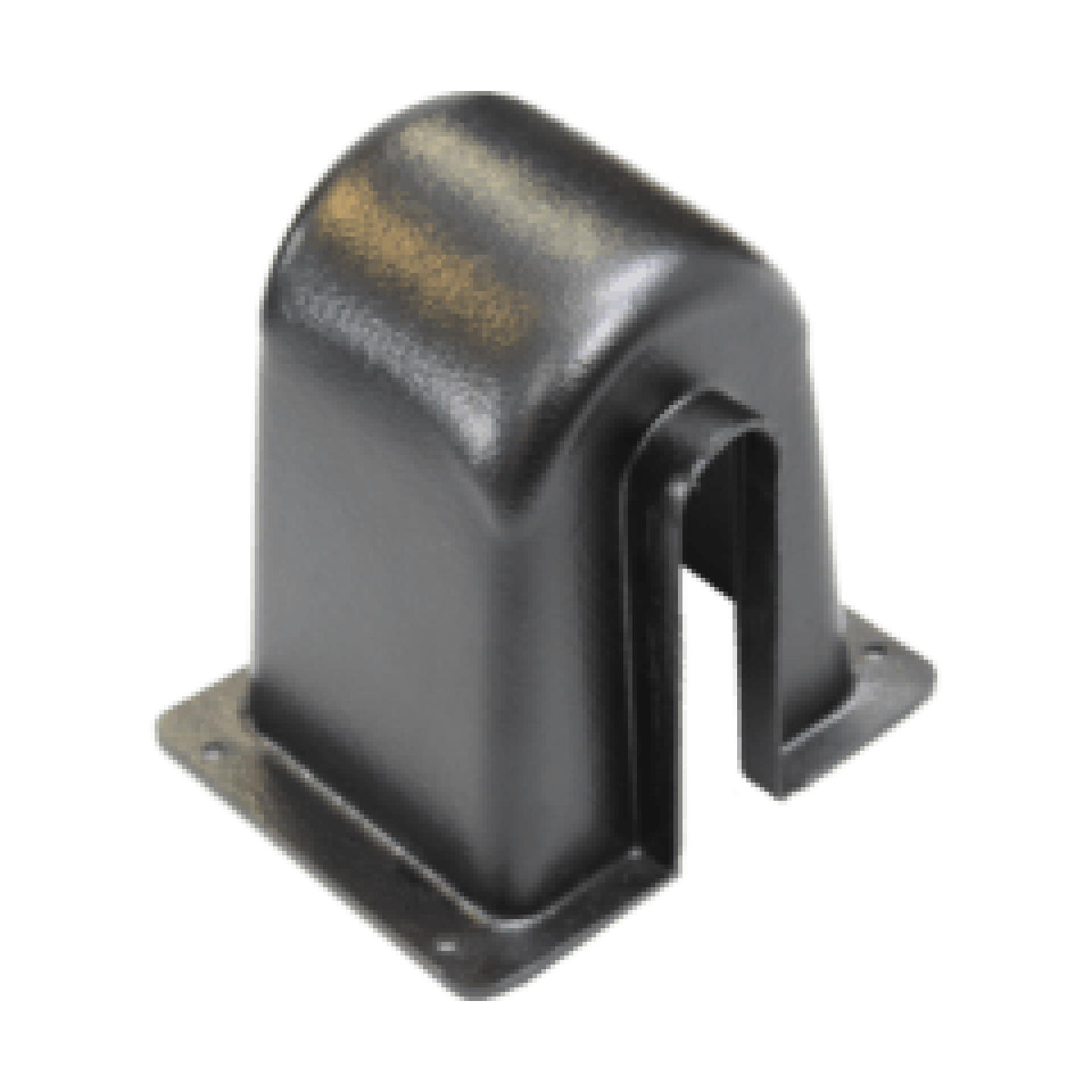

Industrial Transfer Pump and Motor Guard Covers

Used to shield rotating shafts, couplings, belts, and components in industrial pumping system.

Durable, corrosion-resistant covers protect pumps and motors from exposure, debris, and rotating-equipment hazards.

Industrial Pump and Motor Guard Covers are protective enclosures designed to shield workers from rotating shafts, couplings, belts, and pinch points on pump and motor assemblies. Built from heavy-gauge steel, aluminum, or high-strength polymer, these guards provide a rigid physical barrier while maintaining ventilation and easy access for inspection and maintenance. By preventing accidental contact with moving components and containing debris, pump and motor covers help facilities comply with OSHA 1910.219 and 1910.212 machine-guarding standards. Widely used in manufacturing, chemical processing, water treatment, and HVAC systems, these guards enhance operator safety, reduce downtime, and extend equipment life across industrial environments.

User-Friendly Design

- Molded plastic or steel-panel guards enclose rotating couplings, fans, and shaft ends while maintaining airflow and visibility.

- Smooth, rounded edges reduce injury risk and make cleaning simple in harsh or wet environments.

- Hinged or lift-off access panels provide fast inspection access for bearings, couplings, and alignment checks.

- Lightweight design makes installation and removal easier than heavy welded-steel alternatives.

Flexible Mounting Options

- Compatible with direct-drive, belt-drive, and pump-motor base plate configurations.

- Adjustable standoff brackets accommodate pumps and motors of varying frame sizes (NEMA or IEC).

- Available as two-piece, split-cover, or full-enclosure designs depending on coupling exposure and space constraints.

- Custom depth, width, and venting patterns available for unique layouts or high-heat applications.

Seamless System Integration

- Helps facilities meet OSHA 1910.219, NFPA, and ANSI mechanical power-transmission guarding requirements.

- Integrates with facility safety systems—LOTO points, emergency shut-offs, and perimeter guarding.

- Ventilated guard designs support proper cooling airflow across motor housings and pump bearings.

- Compatible with vibration sensors, alignment lasers, and condition-monitoring equipment without obstructing readings.

Industrial Transfer Pump and Motor Guard Covers

Used to shield rotating shafts, couplings, belts, and components in industrial pumping system.

Durable, corrosion-resistant covers protect pumps and motors from exposure, debris, and rotating-equipment hazards.

Industrial Pump and Motor Guard Covers are protective enclosures designed to shield workers from rotating shafts, couplings, belts, and pinch points on pump and motor assemblies. Built from heavy-gauge steel, aluminum, or high-strength polymer, these guards provide a rigid physical barrier while maintaining ventilation and easy access for inspection and maintenance. By preventing accidental contact with moving components and containing debris, pump and motor covers help facilities comply with OSHA 1910.219 and 1910.212 machine-guarding standards. Widely used in manufacturing, chemical processing, water treatment, and HVAC systems, these guards enhance operator safety, reduce downtime, and extend equipment life across industrial environments.

User-Friendly Design

- Molded plastic or steel-panel guards enclose rotating couplings, fans, and shaft ends while maintaining airflow and visibility.

- Smooth, rounded edges reduce injury risk and make cleaning simple in harsh or wet environments.

- Hinged or lift-off access panels provide fast inspection access for bearings, couplings, and alignment checks.

- Lightweight design makes installation and removal easier than heavy welded-steel alternatives.

Flexible Mounting Options

- Compatible with direct-drive, belt-drive, and pump-motor base plate configurations.

- Adjustable standoff brackets accommodate pumps and motors of varying frame sizes (NEMA or IEC).

- Available as two-piece, split-cover, or full-enclosure designs depending on coupling exposure and space constraints.

- Custom depth, width, and venting patterns available for unique layouts or high-heat applications.

Seamless System Integration

- Helps facilities meet OSHA 1910.219, NFPA, and ANSI mechanical power-transmission guarding requirements.

- Integrates with facility safety systems—LOTO points, emergency shut-offs, and perimeter guarding.

- Ventilated guard designs support proper cooling airflow across motor housings and pump bearings.

- Compatible with vibration sensors, alignment lasers, and condition-monitoring equipment without obstructing readings.

- Assembly consists of:

- Pump and motor guard cover (vented, solid, or mesh depending on specification).

- Mounting bracket kit with hardware suitable for pump base plates or motor frames.

- Access panel(s) or removable guard sections for quick inspection.

- Installation instructions with recommended clearances and alignment guidelines.

- Note: Pumps, motors, couplings, and power-transmission components are not included—guarding only.

- Common uses include:

- Industrial pumps (centrifugal, diaphragm, gear, progressive-cavity, and slurry pumps).

- HVAC systems, cooling towers, water-treatment, wastewater plants, chemical processing and food-grade applications.

- Manufacturing and process facilities where couplings, belts, pulleys, and rotating shafts are exposed and require containment.

- Retrofit projects replacing missing or inadequate OEM guarding on legacy pump-motor assemblies.