Power Transmission Guards

Conveyor Guards for Idler Rollers, Drive Belts, and Couplers

Guards protecting idler rollers, drive belts and couplings, engineered for safer material-handling.

Modular guarding for conveyors: secure idlers, drive belts, couplers and nip-points while maintaining maintenance access and operational flow.

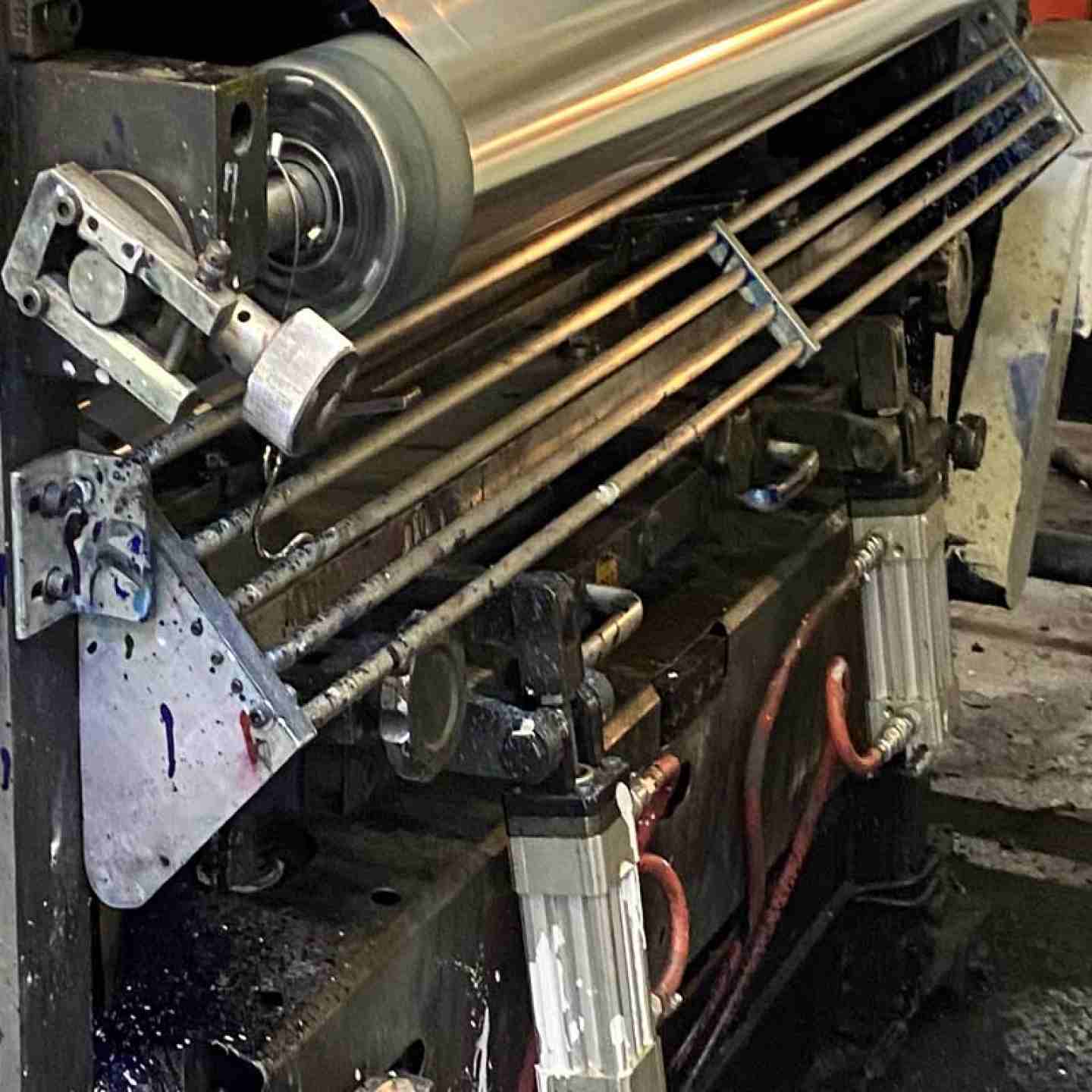

Conveyor Guards for Idler Rollers-Drive Belts-Couplers are engineered safety enclosures designed to protect workers from entanglement, pinch points, and rotating components commonly found along conveyor systems. These guards—built from durable steel, polymer, or wire-mesh panels—fully cover exposed rollers, belt pinch zones, pulleys, couplers, and transition points to prevent accidental contact while maintaining easy access for inspection and maintenance. By reducing the risk of injuries and complying with OSHA 1910.219 and 1910.212 machine-guarding standards, conveyor guards improve operator safety, minimize downtime, and support cleaner, more reliable material-handling operations across manufacturing, packaging, and bulk-processing facilities.

User-Friendly Design

- Precision-cut guard panels and baskets for idler roller nip-points and drive-belt wrap zones.

- Modular mesh or solid panel options allow visual inspection of belts/couplings while preventing operator entry.

- Hinged or removable inspection doors ensure maintenance tasks (belt changes, bearing checks) proceed with minimal downtime.

Flexible Mounting Options

- Guard designs cover non-powered idler rollers (especially in return runs) where nip-point hazards exist if clearance < 50 mm.

- Drive-belt and pulley guards sized for standard belt widths and pulley diameters; mounting brackets adapt to straight or inclined conveyor segments.

- Coupler and shaft cover kits for drive units, adjustable to many iterations of conveyor-drive designs (single/multiple shafts, gearboxes, couplings).

Seamless System Integration

- Guards align with the OSHA 1910.219 requirements for mechanical power-transmission apparatus and nip points.

- Designed as part of a holistic conveyor safety strategy: idler guarding, belt drive covering, coupling protection, access panels and maintenance access points.

- Compatible with safety interlocks, lock-out/tag-out zones, conveyor emergency stop systems and overall machine-safety circuitry.

Conveyor Guards for Idler Rollers, Drive Belts, and Couplers

Guards protecting idler rollers, drive belts and couplings, engineered for safer material-handling.

Modular guarding for conveyors: secure idlers, drive belts, couplers and nip-points while maintaining maintenance access and operational flow.

Conveyor Guards for Idler Rollers-Drive Belts-Couplers are engineered safety enclosures designed to protect workers from entanglement, pinch points, and rotating components commonly found along conveyor systems. These guards—built from durable steel, polymer, or wire-mesh panels—fully cover exposed rollers, belt pinch zones, pulleys, couplers, and transition points to prevent accidental contact while maintaining easy access for inspection and maintenance. By reducing the risk of injuries and complying with OSHA 1910.219 and 1910.212 machine-guarding standards, conveyor guards improve operator safety, minimize downtime, and support cleaner, more reliable material-handling operations across manufacturing, packaging, and bulk-processing facilities.

User-Friendly Design

- Precision-cut guard panels and baskets for idler roller nip-points and drive-belt wrap zones.

- Modular mesh or solid panel options allow visual inspection of belts/couplings while preventing operator entry.

- Hinged or removable inspection doors ensure maintenance tasks (belt changes, bearing checks) proceed with minimal downtime.

Flexible Mounting Options

- Guard designs cover non-powered idler rollers (especially in return runs) where nip-point hazards exist if clearance < 50 mm.

- Drive-belt and pulley guards sized for standard belt widths and pulley diameters; mounting brackets adapt to straight or inclined conveyor segments.

- Coupler and shaft cover kits for drive units, adjustable to many iterations of conveyor-drive designs (single/multiple shafts, gearboxes, couplings).

Seamless System Integration

- Guards align with the OSHA 1910.219 requirements for mechanical power-transmission apparatus and nip points.

- Designed as part of a holistic conveyor safety strategy: idler guarding, belt drive covering, coupling protection, access panels and maintenance access points.

- Compatible with safety interlocks, lock-out/tag-out zones, conveyor emergency stop systems and overall machine-safety circuitry.

- Assembly consists of:

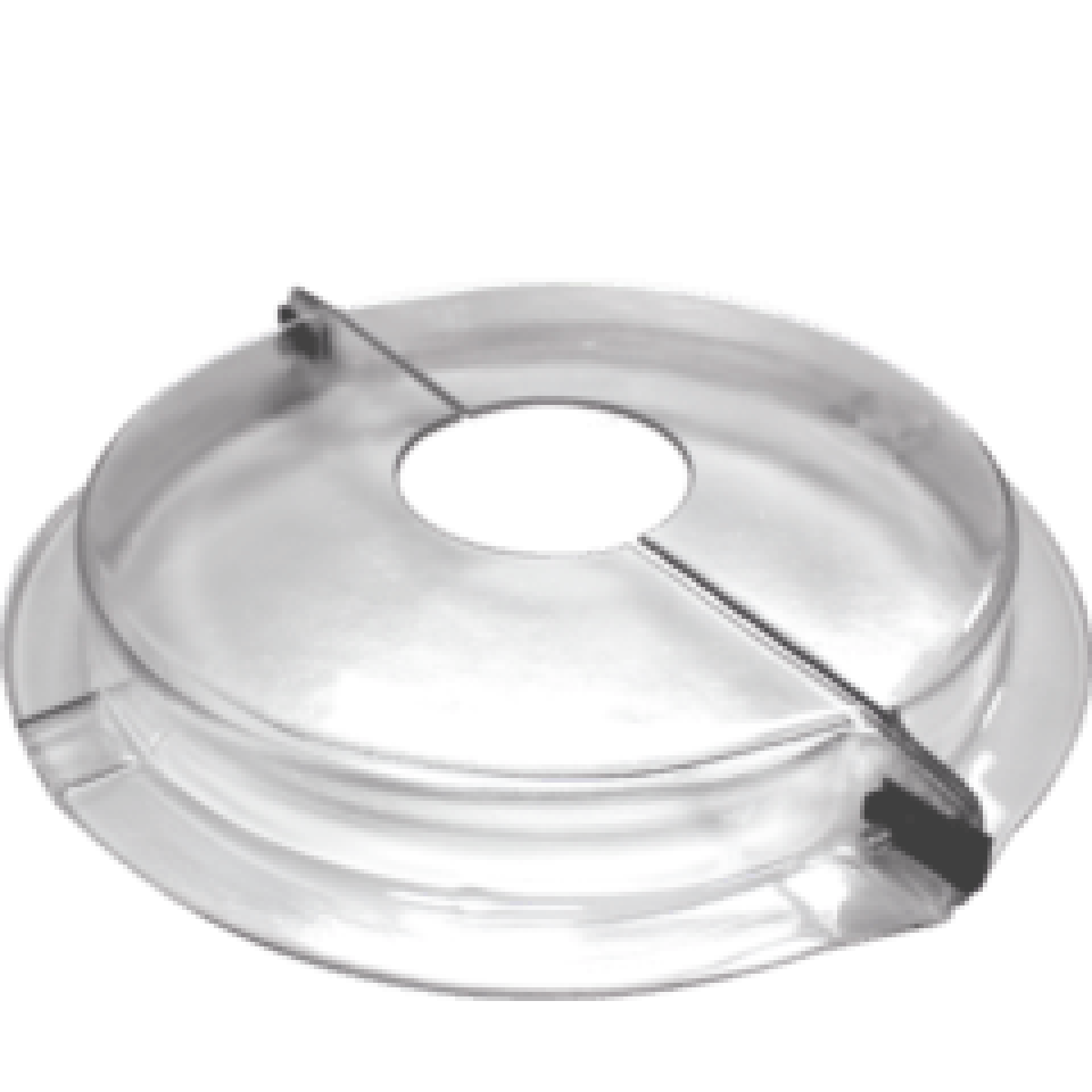

- Guard panels or basket assemblies for idler-roller zones (solid or mesh) sized to specified idler geometry.

- Drive-belt/pulley wrap-zone guard including brackets, fasteners and side-mount panels.

- Coupler/shaft cover module with split-ring or flanged mounting hardware.

- Installation guide with sizing tables, mounting instructions and recommended clearances for nip-point avoidance (minimum clearance 50 mm typical).

- Note: Conveyor belt, idler rollers, drive motor, shafts, and couplings are not included — guard system only.

- Common uses include:

- Heavy-duty belt conveyor systems (mining, bulk material-handling, food & beverage) where idler-return runs and drive belts present entanglement or nip hazards.

- Manufacturing facilities with overhead or inclined belt conveyors requiring full length guarding of belt-and-pulley assemblies.

- Retrofitting older conveyor systems where original guards are missing, damaged or non-compliant with current standards.

- Systems where couplings and drive shafts are exposed and present an operator-risk during material flow, maintenance or jam-clear conditions.