Power Transmission Guards

Belt and Chain Drive Guards and Shields

Guards and shields to contain rotating drives, sprockets and belts while enabling easy inspection.

Modular guarding solutions for belt and chain drives—protecting sprockets, pulleys and transmissions without impeding maintenance.

Belt and Chain Drive Guards and Shields are protective safety enclosures designed to cover rotating belts, chains, sprockets, and pulleys to prevent contact with exposed moving parts. Constructed from durable steel, aluminum, or high-strength polymer materials, these guards create a secure barrier that reduces entanglement, pinch-point, and snag hazards while maintaining visibility and access for routine maintenance. Ideal for conveyors, mixers, pumps, compressors, and other industrial power-transmission systems, belt and chain drive guards help facilities comply with OSHA 1910.219 and 1910.212 machine-guarding standards—improving operator safety, reducing downtime, and extending equipment life in manufacturing environments.

User-Friendly Design

- Clear mesh or polycarbonate viewing panels allow visual inspection of belt and chain tension without full cover removal.

- Tool-free access panels or hinged doors support quick maintenance and reduce downtime.

- Lightweight shield designs can be retrofitted without major machine rework.

Flexible Mounting Options

- Guard modules sized for common belt widths, chain pitch sizes, sprocket diameters—custom sizes also available.

- Mounts for horizontal or vertical drive orientations, open-frame or enclosed layouts.

- Optional split-ring or clamp-on covers for shaft-mounted sprockets where space is constrained.

Seamless System Integration

- Guarding meets OSHA 1910.219, ANSI B11.x and other mechanical power-transmission standards to reduce pinch-point and entanglement hazards.

- Designed to integrate with whole-machine safety strategy—guard doors, interlocks, sensors, and emergency-stop systems.

- Works with your turnkey machine-guarding solutions at PowerSafe Automation for consistent facility-wide safety compliance.

Belt and Chain Drive Guards and Shields

Guards and shields to contain rotating drives, sprockets and belts while enabling easy inspection.

Modular guarding solutions for belt and chain drives—protecting sprockets, pulleys and transmissions without impeding maintenance.

Belt and Chain Drive Guards and Shields are protective safety enclosures designed to cover rotating belts, chains, sprockets, and pulleys to prevent contact with exposed moving parts. Constructed from durable steel, aluminum, or high-strength polymer materials, these guards create a secure barrier that reduces entanglement, pinch-point, and snag hazards while maintaining visibility and access for routine maintenance. Ideal for conveyors, mixers, pumps, compressors, and other industrial power-transmission systems, belt and chain drive guards help facilities comply with OSHA 1910.219 and 1910.212 machine-guarding standards—improving operator safety, reducing downtime, and extending equipment life in manufacturing environments.

User-Friendly Design

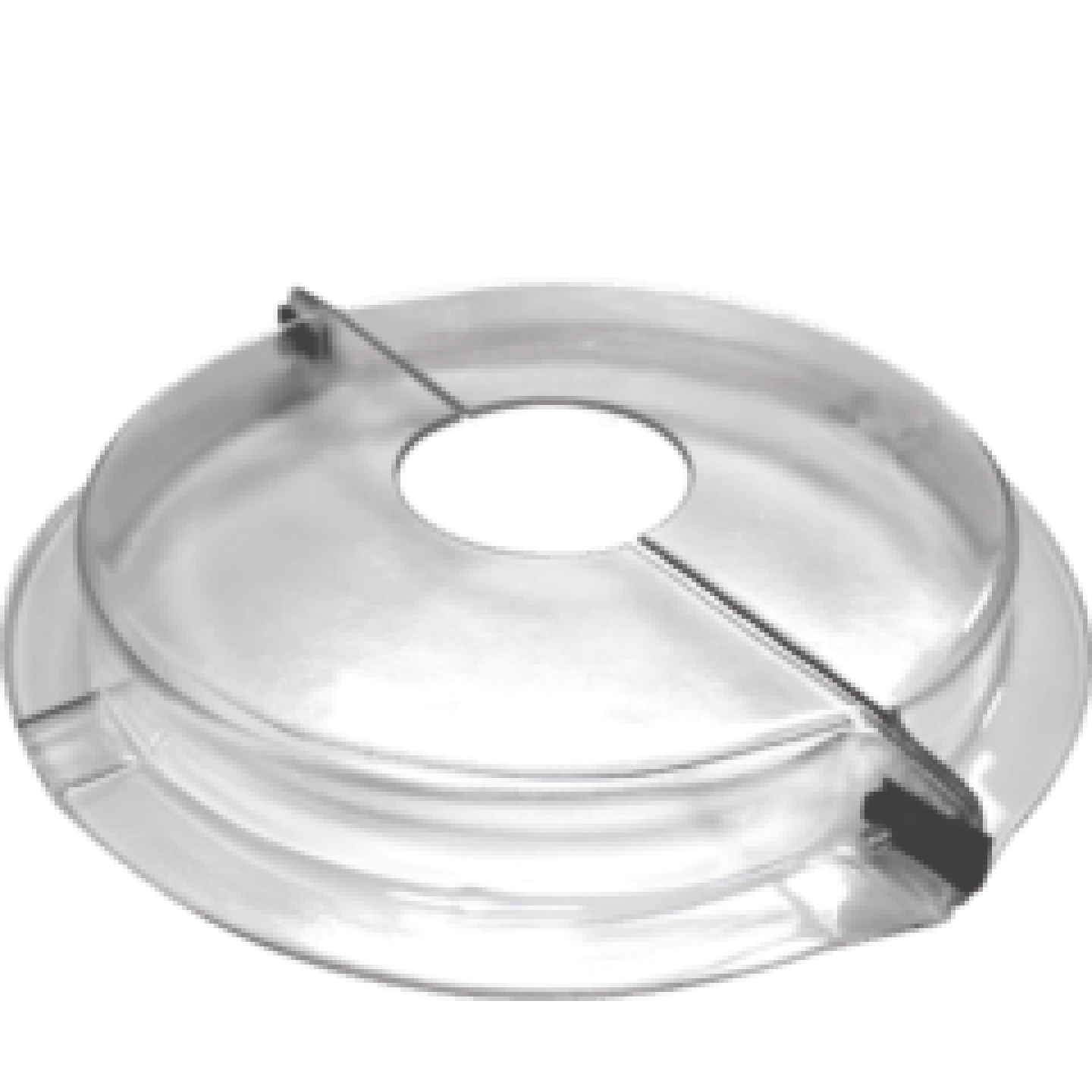

- Clear mesh or polycarbonate viewing panels allow visual inspection of belt and chain tension without full cover removal.

- Tool-free access panels or hinged doors support quick maintenance and reduce downtime.

- Lightweight shield designs can be retrofitted without major machine rework.

Flexible Mounting Options

- Guard modules sized for common belt widths, chain pitch sizes, sprocket diameters—custom sizes also available.

- Mounts for horizontal or vertical drive orientations, open-frame or enclosed layouts.

- Optional split-ring or clamp-on covers for shaft-mounted sprockets where space is constrained.

Seamless System Integration

- Guarding meets OSHA 1910.219, ANSI B11.x and other mechanical power-transmission standards to reduce pinch-point and entanglement hazards.

- Designed to integrate with whole-machine safety strategy—guard doors, interlocks, sensors, and emergency-stop systems.

- Works with your turnkey machine-guarding solutions at PowerSafe Automation for consistent facility-wide safety compliance.

- Assembly consists of:

- Guard panel/shield (mesh or polycarbonate) sized to the drive unit, pulleys or sprockets.

- Mounting brackets, hinges, fasteners and inspection doors.

- Installation guide with sizing tables and recommended clearances (minimum wrap-angle enclosures, minimum distance from nip-points, etc.).

- Note: The drive belts, chains, sprockets, motors, shaft couplings and related components are not included—guarding only.

- Common uses include:

- Fabrication and manufacturing machines with exposed belt drives, chain conveyors, gear drives and open-sprocket systems.

- Food & beverage, packaging, and automotive plants where maintenance access and visual checks are frequent.

- Retrofitting older machines or conveyors lacking adequate guarding, or upgrading to meet modern safety audits.