Machine Tool Guards and Shields

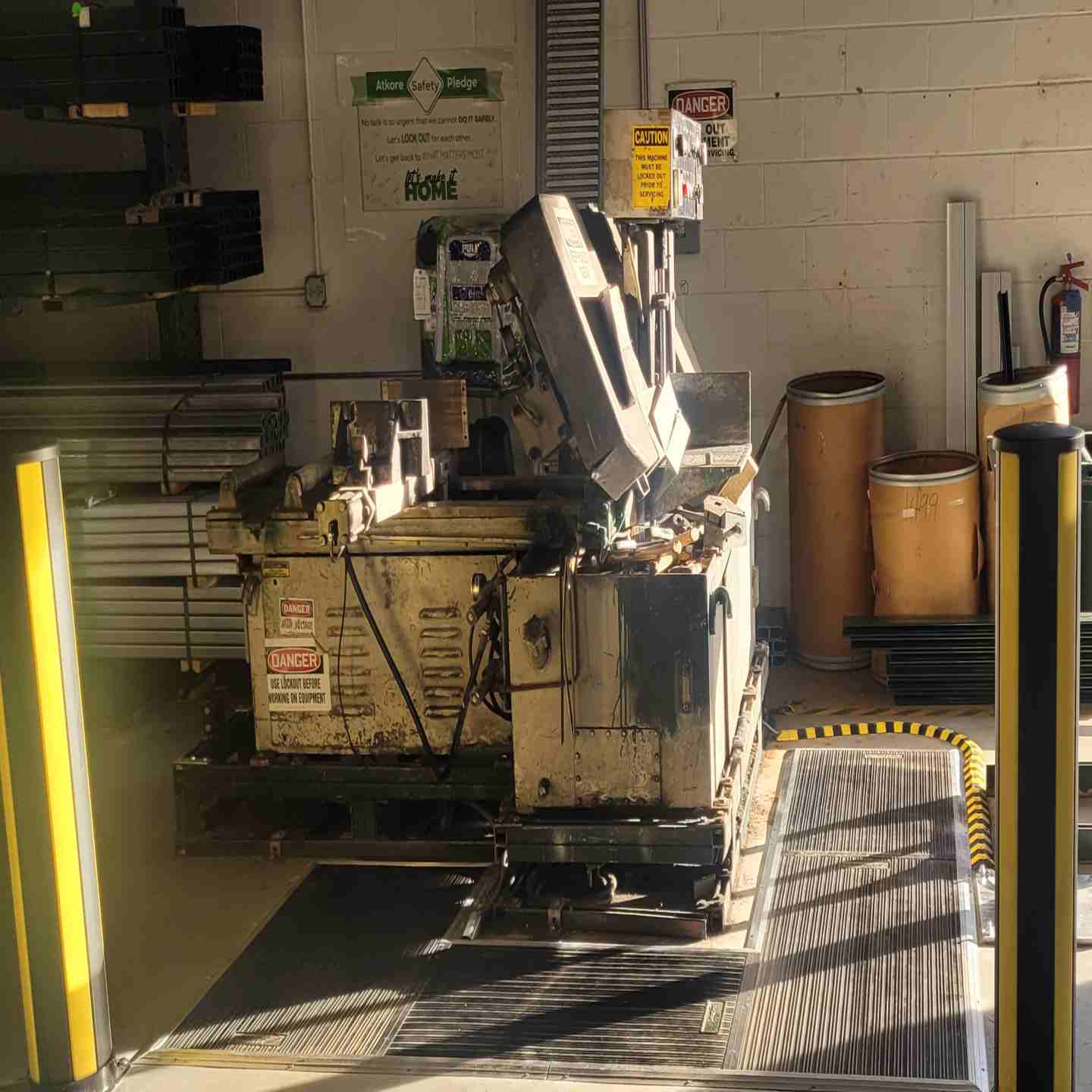

Vertical and Horizontal Bandsaw Guarding

guards designed to protect operators from exposed blades, cutting debris, and pinch points.

Adjustable bandsaw guard shields operators from blade hazards while allowing full cutting visibility.

Vertical & horizontal bandsaws guarding provides essential protection against blade contact, pinch points, and flying debris during cutting operations. Designed with durable steel housings, adjustable blade guards, and clear viewing windows, these safety solutions create a physical barrier while maintaining full visibility of the cut line. Whether used on floor-standing vertical saws or horizontal metal-cutting bandsaws, proper guarding helps shops comply with OSHA 1910.213 and 1910.212 machine-guarding requirements by shielding operators from exposed blades and moving components. Upgrading to modern bandsaw guards enhances operator safety, reduces injury risk, and supports safer, more compliant metalworking and woodworking environments.

User-Friendly Design

- Shatter-resistant shields for each wheel provide unobstructed line of sight.

- Adjustable eye shields, spark guards, and tool-rest coverage.

- Quick-adjust knobs allow fast setup for beveling or deburring operations.

Flexible Mounting Options

- Compatible with 6”, 8”, 10”, and 12” bench/pedestal grinders.

- Bolt-on brackets adapt to various motor housings and wheel guards.

- Optional extended spark-containment panels.

Seamless System Integration

- Optional interlock prevents spindle rotation when shields are raised.

- Meets OSHA 1910.215 grinder-guarding and exposure-angle requirements.

- Integrates with stop switches and E-stop circuits.

Vertical and Horizontal Bandsaw Guarding

guards designed to protect operators from exposed blades, cutting debris, and pinch points.

Adjustable bandsaw guard shields operators from blade hazards while allowing full cutting visibility.

Vertical & horizontal bandsaws guarding provides essential protection against blade contact, pinch points, and flying debris during cutting operations. Designed with durable steel housings, adjustable blade guards, and clear viewing windows, these safety solutions create a physical barrier while maintaining full visibility of the cut line. Whether used on floor-standing vertical saws or horizontal metal-cutting bandsaws, proper guarding helps shops comply with OSHA 1910.213 and 1910.212 machine-guarding requirements by shielding operators from exposed blades and moving components. Upgrading to modern bandsaw guards enhances operator safety, reduces injury risk, and supports safer, more compliant metalworking and woodworking environments.

User-Friendly Design

- Shatter-resistant shields for each wheel provide unobstructed line of sight.

- Adjustable eye shields, spark guards, and tool-rest coverage.

- Quick-adjust knobs allow fast setup for beveling or deburring operations.

Flexible Mounting Options

- Compatible with 6”, 8”, 10”, and 12” bench/pedestal grinders.

- Bolt-on brackets adapt to various motor housings and wheel guards.

- Optional extended spark-containment panels.

Seamless System Integration

- Optional interlock prevents spindle rotation when shields are raised.

- Meets OSHA 1910.215 grinder-guarding and exposure-angle requirements.

- Integrates with stop switches and E-stop circuits.

- Assembly consists of:

- Polycarbonate or mesh guard assembly.

- Height-adjustable mounting arms and hardware.

- Installation manual + optional wiring diagram.

- Common uses include:

- Metal fab, wood shops, and general machining.

- High-chip cutting and production environments.

- Retrofits for older unguarded bandsaws.