Integrated Machine Safety Controls

Two-Hand Controls with Anti-Tie-Down Safety Relay

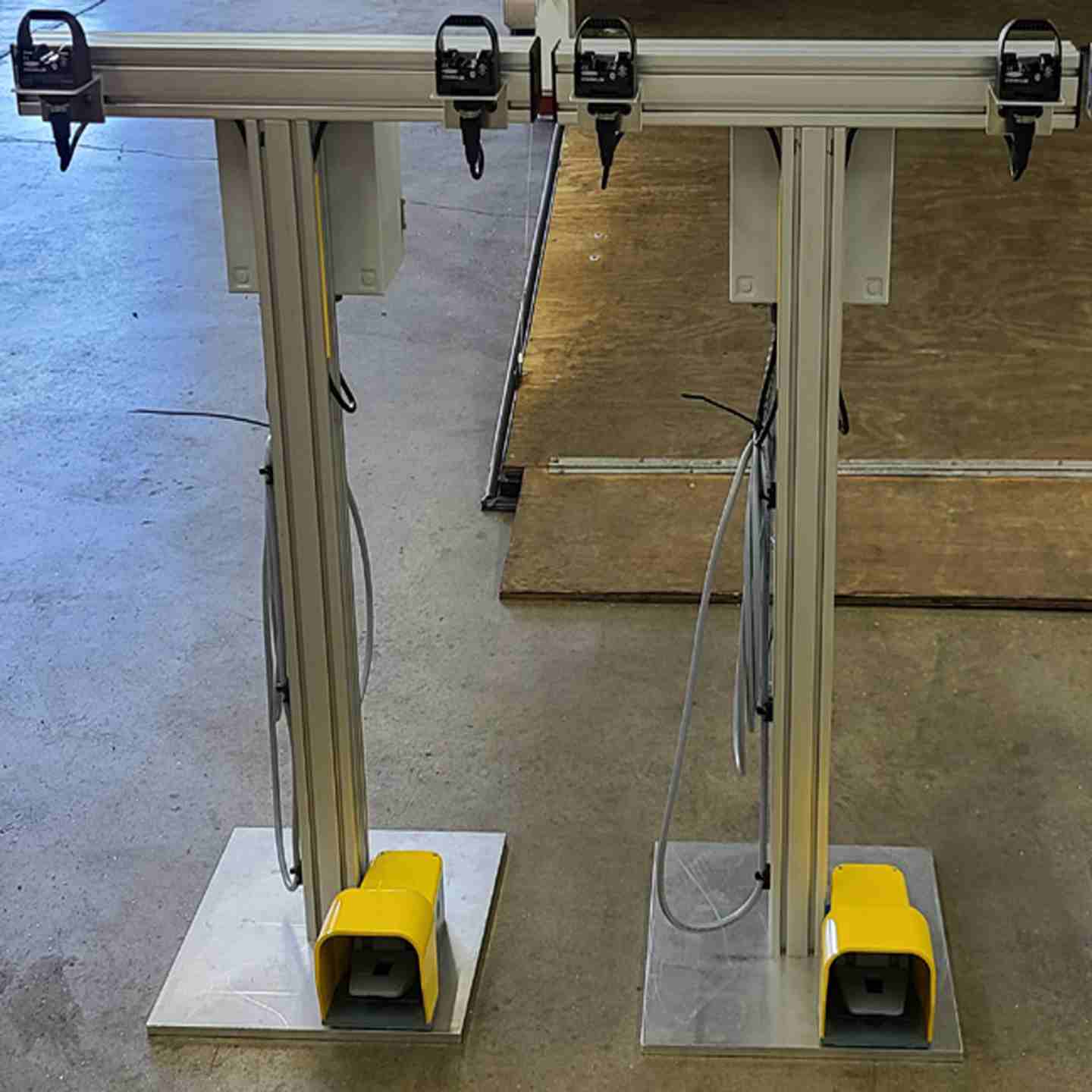

Redundant two-hand control system with anti-tie-down logic, ensuring safe machine cycles.

Dual-button safety control with anti-tie-down, ensuring both hands are present before machine actuation.

Two-hand controls with an anti–tie-down safety relay are operator-initiated safety devices designed to ensure that both hands are intentionally and simultaneously used to start a hazardous machine cycle. By requiring both actuating buttons to be pressed within a set time window—and held continuously—the system prevents operators from bypassing the controls, reaching into danger zones, or using improvised tools (“tie-downs”) to defeat the safety function. Integrated with a Category 3/PLd or Category 4/PLe safety relay, two-hand control systems monitor timing, redundancy, and contact integrity to guarantee proper operation. Commonly used on presses, cutters, shears, and high-force machinery, these systems help facilities comply with OSHA, ANSI B11, and ISO 13851 standards—delivering reliable, ergonomically safe machine-cycle initiation and reducing risk during hands-on operations.

User-Friendly Design

- Dual-palm station requires simultaneous operation of both buttons to start a machine cycle, protecting hands from pinch and point-of-operation hazards.

- Ergonomic button spacing prevents accidental activation and reduces operator fatigue during repetitive cycles.

- Large, high-visibility, industrial push buttons designed for gloved-hand use in harsh manufacturing environments.

- Built-in LED status indicators provide clear feedback for ready, fault, and active states.

Flexible Mounting Options

- Pedestal-mount, machine-mount, or workstation-mounted options for optimal operator reach and ergonomic posture.

- Compatible with t-slotted aluminum frames, steel guarding frames, operator stations, and adjustable-height stands.

- Optional armrests, wrist guards, and adjustable button spacing for custom ergonomic needs.

- Can be wired for single-operator or dual-operator configurations depending on process risk.

Seamless System Integration

- Anti-tie-down safety relay logic ensures both buttons are pressed within a defined time window, preventing defeat or single-hand activation.

- Meets or supports ISO 13851 (two-hand control), ISO 13849 (PLd/PLe), and ANSI/RIA machine-safety requirements.

- Relay provides redundant safety outputs, monitored reset, and fault detection for shorts, welded contacts, and button failure.

- Integrates with presses, forming machines, cutters, pneumatically actuated tooling, and high-force or high-speed hazardous cycles.

- Available in 24VDC safety relay packages compatible with light curtains, interlocks, E-stops, and full machine safety circuits.

Two-Hand Controls with Anti-Tie-Down Safety Relay

Redundant two-hand control system with anti-tie-down logic, ensuring safe machine cycles.

Dual-button safety control with anti-tie-down, ensuring both hands are present before machine actuation.

Two-hand controls with an anti–tie-down safety relay are operator-initiated safety devices designed to ensure that both hands are intentionally and simultaneously used to start a hazardous machine cycle. By requiring both actuating buttons to be pressed within a set time window—and held continuously—the system prevents operators from bypassing the controls, reaching into danger zones, or using improvised tools (“tie-downs”) to defeat the safety function. Integrated with a Category 3/PLd or Category 4/PLe safety relay, two-hand control systems monitor timing, redundancy, and contact integrity to guarantee proper operation. Commonly used on presses, cutters, shears, and high-force machinery, these systems help facilities comply with OSHA, ANSI B11, and ISO 13851 standards—delivering reliable, ergonomically safe machine-cycle initiation and reducing risk during hands-on operations.

User-Friendly Design

- Dual-palm station requires simultaneous operation of both buttons to start a machine cycle, protecting hands from pinch and point-of-operation hazards.

- Ergonomic button spacing prevents accidental activation and reduces operator fatigue during repetitive cycles.

- Large, high-visibility, industrial push buttons designed for gloved-hand use in harsh manufacturing environments.

- Built-in LED status indicators provide clear feedback for ready, fault, and active states.

Flexible Mounting Options

- Pedestal-mount, machine-mount, or workstation-mounted options for optimal operator reach and ergonomic posture.

- Compatible with t-slotted aluminum frames, steel guarding frames, operator stations, and adjustable-height stands.

- Optional armrests, wrist guards, and adjustable button spacing for custom ergonomic needs.

- Can be wired for single-operator or dual-operator configurations depending on process risk.

Seamless System Integration

- Anti-tie-down safety relay logic ensures both buttons are pressed within a defined time window, preventing defeat or single-hand activation.

- Meets or supports ISO 13851 (two-hand control), ISO 13849 (PLd/PLe), and ANSI/RIA machine-safety requirements.

- Relay provides redundant safety outputs, monitored reset, and fault detection for shorts, welded contacts, and button failure.

- Integrates with presses, forming machines, cutters, pneumatically actuated tooling, and high-force or high-speed hazardous cycles.

- Available in 24VDC safety relay packages compatible with light curtains, interlocks, E-stops, and full machine safety circuits.

- Assembly consists of:

- Two-hand palm button station (dual-pushbutton housing).

- Anti-tie-down safety relay with redundant force-guided contacts.

- Wiring diagram for 24VDC safety control integration.

- Optional pedestal stand and mounting hardware.

- Installation, reset, and safety-distance guidance documentation.

- Note: Press, actuator, valves, and downstream machine controls are not included.

- Common uses include:

- Stamping presses, punch presses, forming presses, and clamping operations.

- High-force pneumatic or hydraulic machines requiring operator presence verification.

- Equipment where presence-sensing devices (light curtains/radar) cannot be used due to tooling geometry.

- Retrofit safety upgrades on legacy machinery lacking compliant control systems.

- Situations requiring reduced risk of operator bypass, accidental actuation, or defeat of manual actuation controls.