Integrated Machine Safety Controls

Intrinsic Safety Control Systems

Designed for hazardous locations where electrical ignition risks must be eliminated at the source.

Low-energy intrinsically safe circuits prevent sparks, heat, or ignition in hazardous machine zones.

Intrinsic safety components are engineered to prevent ignition in hazardous environments by limiting electrical energy to safe levels. Used in applications involving flammable gases, dust, or vapors, intrinsic safety relays, barriers, and interfaces ensure control circuits cannot generate sparks or excessive heat. These devices comply with OSHA, NEC, ATEX, and IECEx standards—making them ideal for chemical processing, paint booths, battery manufacturing, and any classified hazardous location. Intrinsic safety protects operators, prevents explosions, and ensures safe integration of sensors, switches, and controls in hazardous industrial zones.

User-Friendly Design

- Engineered to limit voltage and current for safe operation in explosive or flammable atmospheres.

- Compact IS barriers and isolators simplify wiring inside control panels.

- LED diagnostics and status lights improve troubleshooting and system visibility.

Flexible Mounting Options

- DIN-rail, junction-box, or field-mount options for harsh or classified environments.

- Compatible with sensors, switches, and field devices requiring IS-rated power.

- Suitable for Class I, II, III Div 1 & 2 zones depending on component selection.

Seamless System Integration

- Works with existing machine safety circuits, E-stops, interlocks, and PLC safety modules.

- Supports compliance with UL, FM, ATEX/IECEx requirements for hazardous locations.

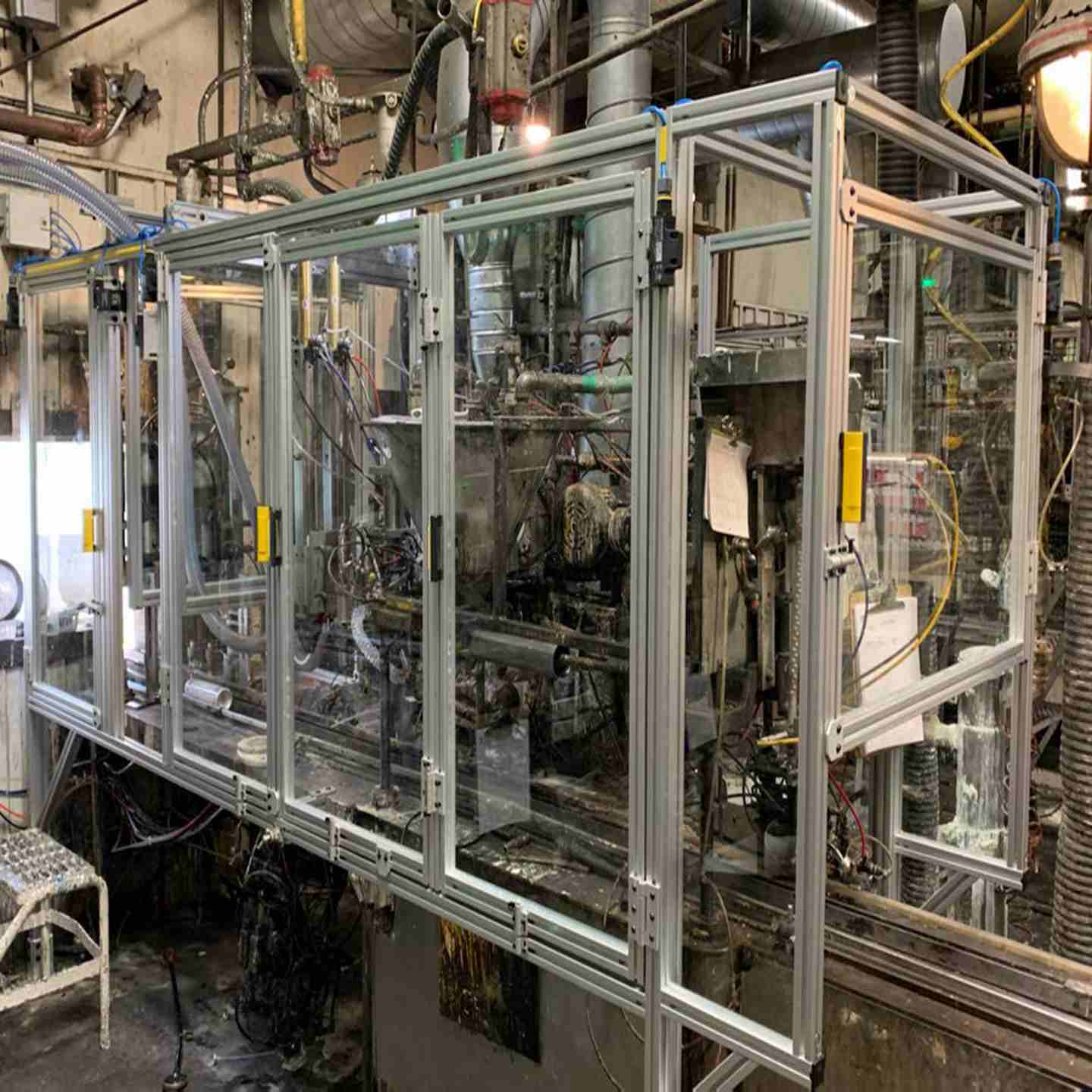

- Ideal for integrating IS devices into PowerSafe machine guarding and automation cells.

Intrinsic Safety Control Systems

Designed for hazardous locations where electrical ignition risks must be eliminated at the source.

Low-energy intrinsically safe circuits prevent sparks, heat, or ignition in hazardous machine zones.

Intrinsic safety components are engineered to prevent ignition in hazardous environments by limiting electrical energy to safe levels. Used in applications involving flammable gases, dust, or vapors, intrinsic safety relays, barriers, and interfaces ensure control circuits cannot generate sparks or excessive heat. These devices comply with OSHA, NEC, ATEX, and IECEx standards—making them ideal for chemical processing, paint booths, battery manufacturing, and any classified hazardous location. Intrinsic safety protects operators, prevents explosions, and ensures safe integration of sensors, switches, and controls in hazardous industrial zones.

User-Friendly Design

- Engineered to limit voltage and current for safe operation in explosive or flammable atmospheres.

- Compact IS barriers and isolators simplify wiring inside control panels.

- LED diagnostics and status lights improve troubleshooting and system visibility.

Flexible Mounting Options

- DIN-rail, junction-box, or field-mount options for harsh or classified environments.

- Compatible with sensors, switches, and field devices requiring IS-rated power.

- Suitable for Class I, II, III Div 1 & 2 zones depending on component selection.

Seamless System Integration

- Works with existing machine safety circuits, E-stops, interlocks, and PLC safety modules.

- Supports compliance with UL, FM, ATEX/IECEx requirements for hazardous locations.

- Ideal for integrating IS devices into PowerSafe machine guarding and automation cells.

- Assembly consists of:

- Intrinsic safety barrier/isolator module.

- Terminal labeling, mounting hardware.

- Wiring diagram and safety compliance documentation.

- Note: Field devices and sensors sold separately.

- Common uses include:

- Chemical processing, metal finishing, plastics, food production with flammable dusts.

- Tanks, mixers, grinders, conveyors in explosive atmospheres.

- Any environment requiring electrical safety without declassifying the area.