Custom Machine Guarding

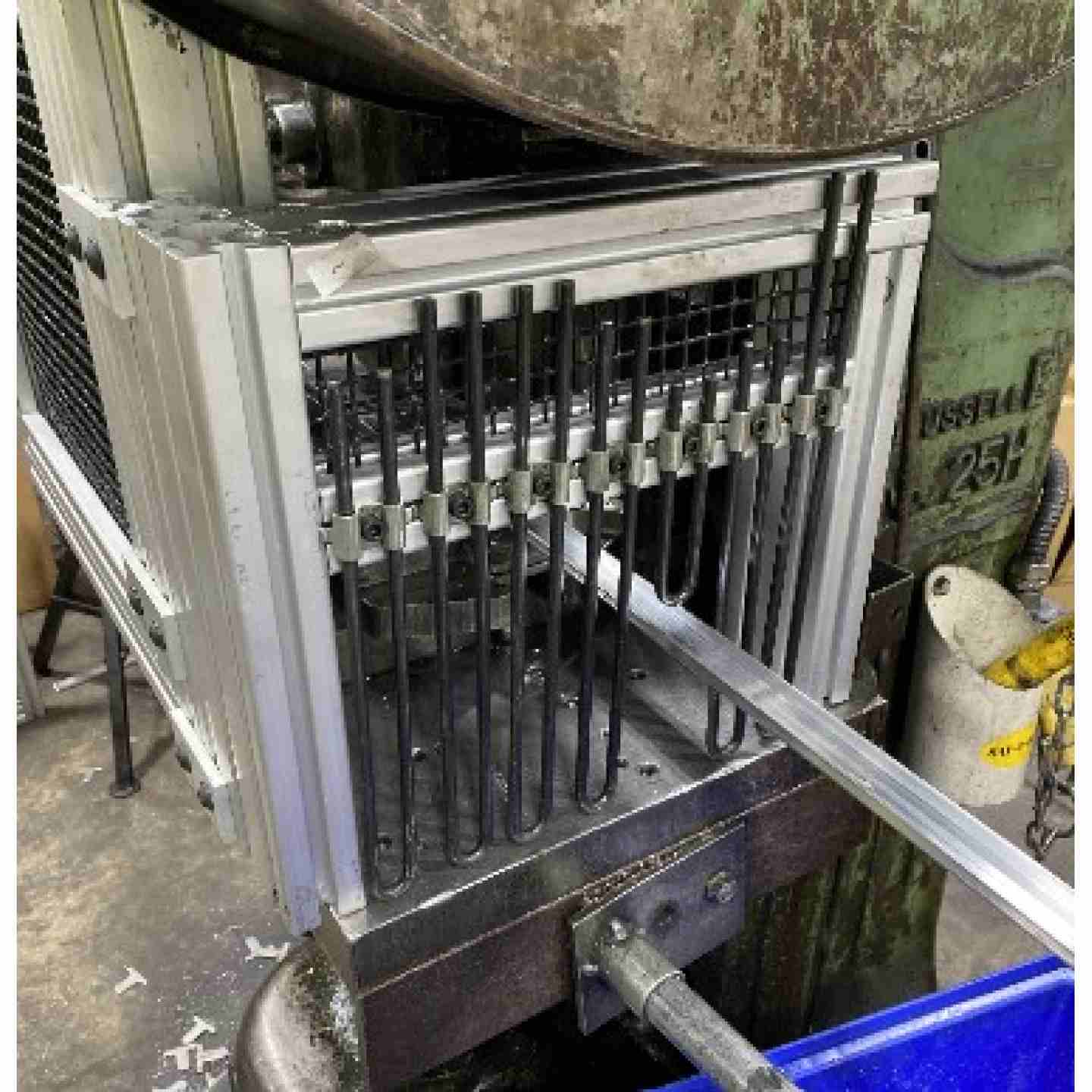

Stamping and Punch Press Guards

For stamping and punch presses, designed to protect operators from high-force tooling hazards.

Reinforced guards shield operators from pinch points, ejection hazards, and tooling impact zones.

Stamping and punch press guards are heavy-duty safety systems engineered to protect operators from high-force pinch points, flying parts, and ejection hazards created during press operations. Designed using steel frames, Lexan/polycarbonate shielding, light curtains, or presence-sensing devices, these guards secure the point of operation while allowing full visibility and easy material handling. Press guarding helps manufacturers comply with OSHA 1910.217 and ANSI B11.1 standards—improving safety, reducing downtime, and preventing severe injuries in metal stamping, forming, and fabrication environments.

User-Friendly Design

- Thick polycarbonate or steel mesh withstands impact from ejected parts.

- Quick-open sections allow rapid die changes.

- Custom shapes fit irregular press frames.

Flexible Mounting Options

- Hinged, sliding, or lift-up configurations.

- Compatible with mechanical, hydraulic, and pneumatic presses.

- Optional integration with two-hand controls.

Seamless System Integration

- Works with light curtains, die safety blocks, and barrier guards.

- Meets ANSI B11.1 and OSHA 1910.217 guard requirements.

- Interlocks prevent cycling unless guard is fully closed.

Stamping and Punch Press Guards

For stamping and punch presses, designed to protect operators from high-force tooling hazards.

Reinforced guards shield operators from pinch points, ejection hazards, and tooling impact zones.

Stamping and punch press guards are heavy-duty safety systems engineered to protect operators from high-force pinch points, flying parts, and ejection hazards created during press operations. Designed using steel frames, Lexan/polycarbonate shielding, light curtains, or presence-sensing devices, these guards secure the point of operation while allowing full visibility and easy material handling. Press guarding helps manufacturers comply with OSHA 1910.217 and ANSI B11.1 standards—improving safety, reducing downtime, and preventing severe injuries in metal stamping, forming, and fabrication environments.

User-Friendly Design

- Thick polycarbonate or steel mesh withstands impact from ejected parts.

- Quick-open sections allow rapid die changes.

- Custom shapes fit irregular press frames.

Flexible Mounting Options

- Hinged, sliding, or lift-up configurations.

- Compatible with mechanical, hydraulic, and pneumatic presses.

- Optional integration with two-hand controls.

Seamless System Integration

- Works with light curtains, die safety blocks, and barrier guards.

- Meets ANSI B11.1 and OSHA 1910.217 guard requirements.

- Interlocks prevent cycling unless guard is fully closed.

- Assembly consists of:

- Custom guard panels and brackets.

- Optional interlock hardware.

- Installation and safety documentation.

- Common uses include:

- Punch presses

- Stamping presses

- Riveters

- Forming machines