Custom Machine Guarding

Machine Guards for Food Processing

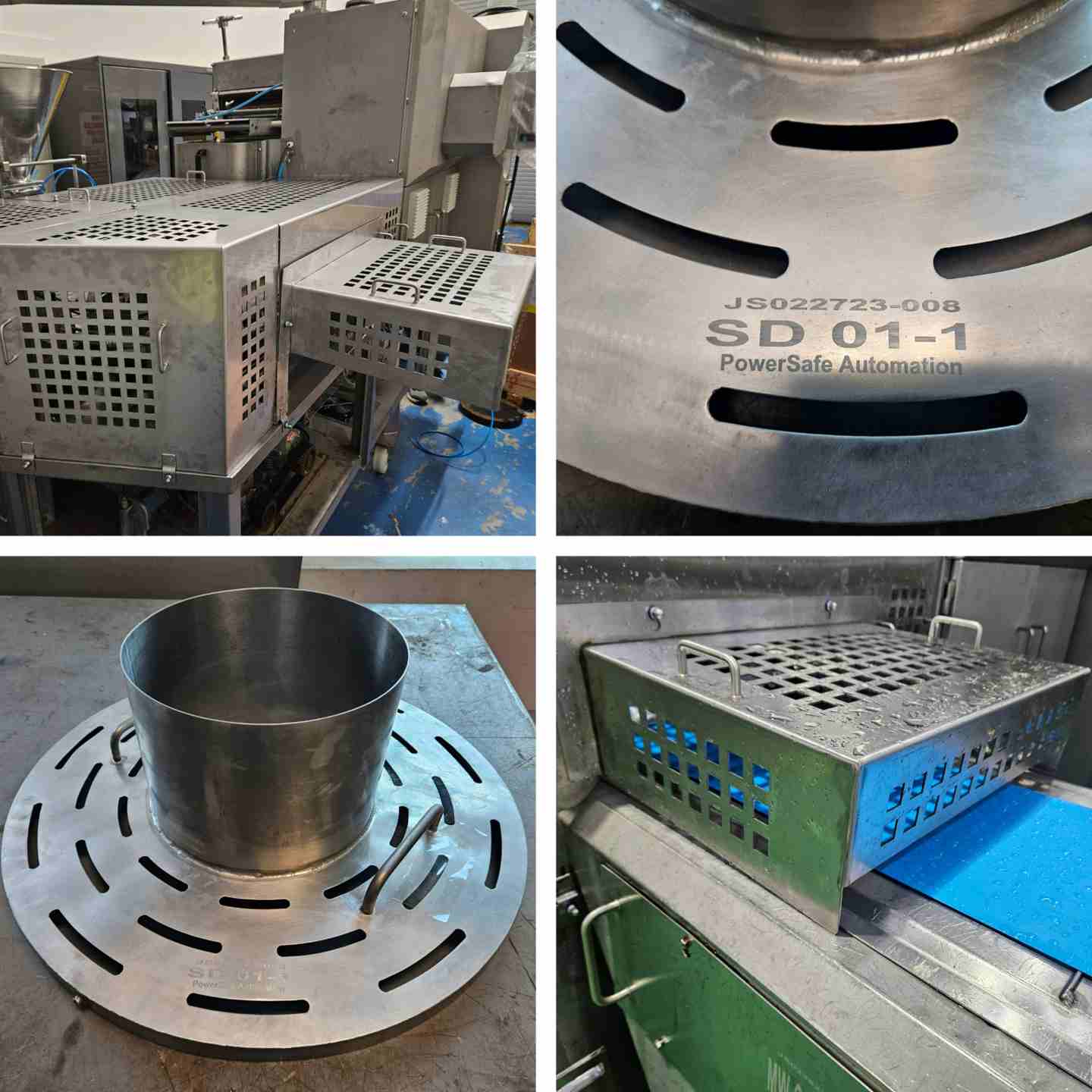

Food-grade machine guarding designed with hygienic materials and wash-down capabilities.

Sanitary guarding engineered for food processing machinery with FDA-approved materials and wash-down safe construction.

Machine guards for food-processing equipment are hygienic, stainless-steel or FDA-approved polymer enclosures designed to protect workers from moving parts while maintaining food-grade sanitation. Smooth surfaces, easy-clean designs, and corrosion-resistant materials prevent contamination and support rapid washdown. These guards help processors comply with OSHA 1910.212, FDA, and USDA requirements while improving operator safety around slicers, conveyors, mixers, grinders, packaging lines, and automated food-production machinery.

User-Friendly Design

- Smooth surfaces with no crevices for bacterial growth.

- Polycarbonate or stainless-steel guard panels withstand harsh cleaning.

- Tool-free removal for sanitation cycles.

Flexible Mounting Options

- Stainless frames, t-slot frames, or hybrid designs.

- USDA/FDA-compliant hardware and corrosion-proof fasteners.

- Compatible with conveyors, slicers, mixers, fillers, and packaging equipment.

Seamless System Integration

- Integrates with CIP systems, wash-down stations, and sanitizing chemicals.

- Supports interlocks and sensors rated for wet environments.

- Meets food-safety and machinery-guarding standards.

Machine Guards for Food Processing

Food-grade machine guarding designed with hygienic materials and wash-down capabilities.

Sanitary guarding engineered for food processing machinery with FDA-approved materials and wash-down safe construction.

Machine guards for food-processing equipment are hygienic, stainless-steel or FDA-approved polymer enclosures designed to protect workers from moving parts while maintaining food-grade sanitation. Smooth surfaces, easy-clean designs, and corrosion-resistant materials prevent contamination and support rapid washdown. These guards help processors comply with OSHA 1910.212, FDA, and USDA requirements while improving operator safety around slicers, conveyors, mixers, grinders, packaging lines, and automated food-production machinery.

User-Friendly Design

- Smooth surfaces with no crevices for bacterial growth.

- Polycarbonate or stainless-steel guard panels withstand harsh cleaning.

- Tool-free removal for sanitation cycles.

Flexible Mounting Options

- Stainless frames, t-slot frames, or hybrid designs.

- USDA/FDA-compliant hardware and corrosion-proof fasteners.

- Compatible with conveyors, slicers, mixers, fillers, and packaging equipment.

Seamless System Integration

- Integrates with CIP systems, wash-down stations, and sanitizing chemicals.

- Supports interlocks and sensors rated for wet environments.

- Meets food-safety and machinery-guarding standards.

- Assembly consists of:

- Hygienic guard panels and frames.

- Stainless hardware.

- Sanitation and inspection guidelines.

- Common uses include:

- Meat processing

- Bakery

- Produce

- Dairy

- Beverage

- Packaging lines