PowerSafe partners with factories in the industrial motion industry, understanding their unique challenges. High-speed machines with mechanical, pneumatic, and hydraulic components make it difficult to implement safety measures without disrupting functionality. However, with so many moving parts, a well-designed machine guarding solution is essential to protect operators while maintaining efficiency.

Common Hazards

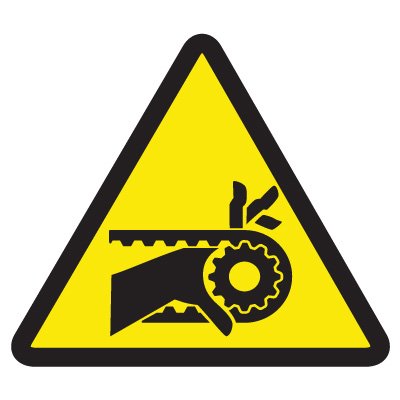

Machines and production lines contain numerous hazards, both visible and hidden, that pose risks to operators. Rollers and saw blades, whether motor-driven or moved by material and conveyor belts, create active dangers that require proper hazard mitigation including:

- Chain drive entanglement

- Sever points

- Pinch points

- Crush points

- Shear points

Common Machinery

Legacy equipment in the Industrial Motion Industry often lacks essential OSHA safety controls, has obsolete parts, or suffers from wear and corrosion. Common machine types in this industry include:

- Planers

- Hobbers

- Shapers

- Milling machines

- Broaches

- Flame hardeners

- Manual lathes

Guarding Solutions

The wide range of guarding solutions that can be created through operators, maintenance, and safety cooperation in collaboration with machine safety experts include:

Machine Guarding Solutions

- End Shaft Bearing Covers - Shields exposed shaft ends, preventing accidental contact while maintaining accessibility for maintenance.

- Pillow Block Caps - Encloses bearings to protect operators from rotating components while reducing contamination risks.

- Gear and Sprocket Guards - Covers moving gears and sprockets, preventing entanglement hazards while allowing visibility for inspections.

- Pump and Motor Coupler Guards

- Linear Actuator Shields - Safeguards exposed linear actuators, preventing pinch points while allowing smooth machine operation.

- Pneumatic and Hydraulic Cylinder Guards - Encloses high-pressure components, reducing risks from moving parts and potential leaks.

Integrated Safety Controls

- Safety Encoders

- Extended-reach maintenance tools

- 2-hand controls

- Pneumatic and hydraulic safety valves

- CNC spin windows for visibility

Our machine guarding designs are built to custom fit your specific machine, application, and operational needs while remaining user-friendly to create a safer work environment. Any impact on production will depend on necessary machine upgrades or process changes, which should be evaluated internally. Machine guards and perimeter fencing are essential for employee protection and should be a top priority at your facility.