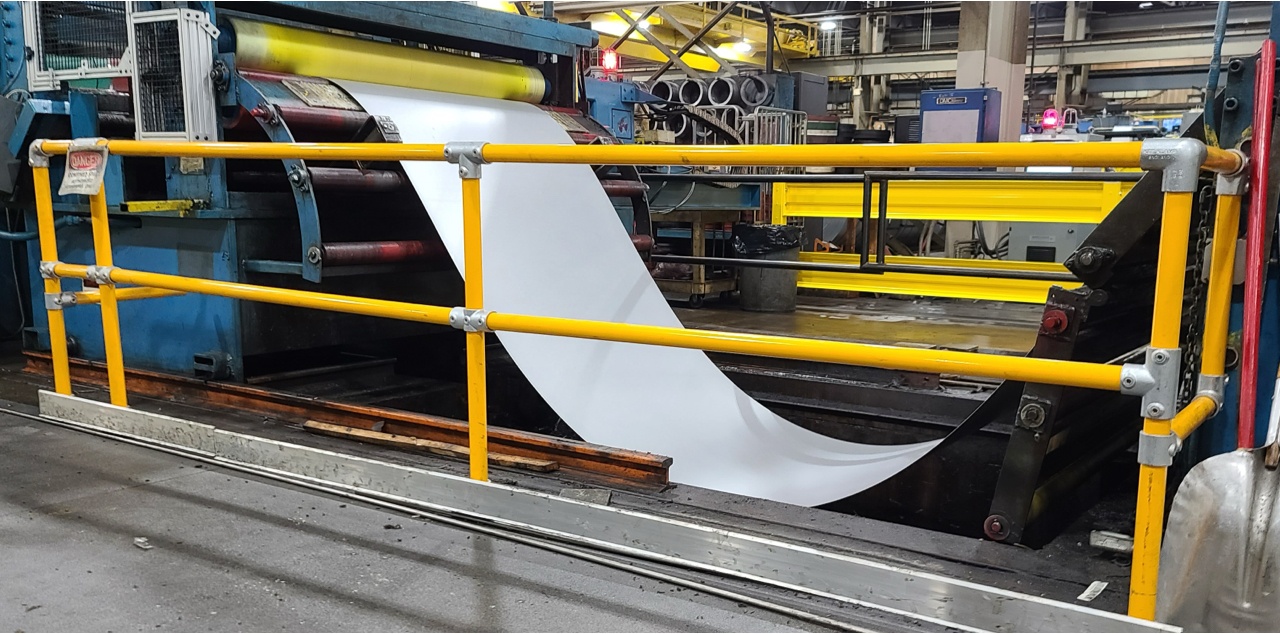

Turnkey Machine Guarding Process

Choose a Partner. Not a Supplier.

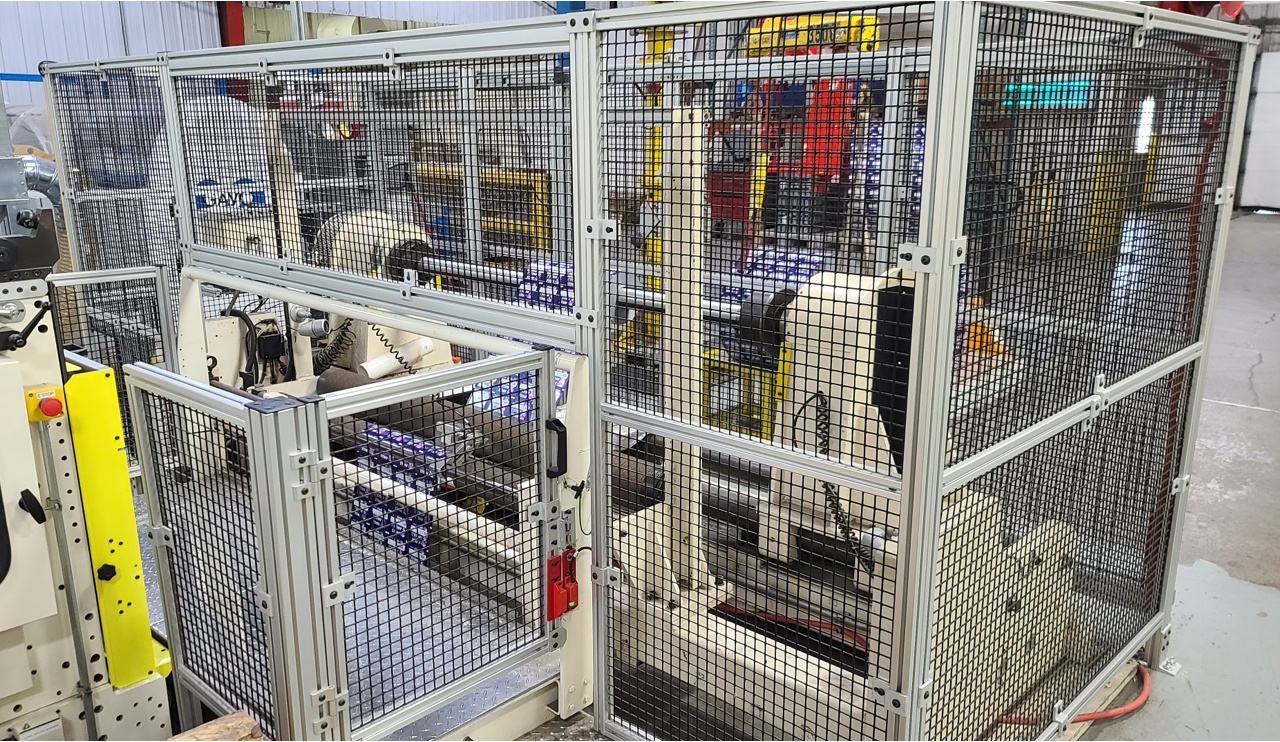

Unlike vendors who sell fencing or off-the-shelf parts, we work directly with your team to design custom machine guarding solutions built around your equipment and process.

From assessment to final installation, our engineer-led turnkey approach keeps your machines compliant and operations running smoothly, without adding to your workload.

Get a Free Guarding Assessment

Prefer to watch instead? Check out our Turnkey Guarding Process videos on our YouTube Channel.

A Sales Engineer visits your site to assess machine safety alongside your team, evaluating key factors like hazard mitigation, accessibility, stop-time distances, and ergonomic risks to develop a fully customized guarding solution.

Learn more about the Assessment Process →

Following the assessment, our engineers create detailed 3D CAD models and a scope of work for your facility, focusing on engineered safety solutions over administrative controls. You’ll receive a full turnkey quote that includes:

- Design Presentations

- Materials

- Installation Plans

- Integration Options

- Schematics

- Recommended spare parts for ongoing maintenance

Learn more about our Design Process →

Once approved, we conduct a final on-site review before manufacturing your custom solution using Rexroth aluminum, steel, or powder-coated materials (either sub-assembled or fully built). Safety controls are tested, installation is scheduled, and all deliverables are prepped for deployment.

Learn more about our Manufacturing Process →

During on-site installation and integration, our technicians implement physical guarding, e-safety devices, and conduct a safety program review with your team. We commission the system alongside your maintenance staff and provide schematics and spare parts for ongoing support.

Learn more about our Nationwide Guarding Installation →

Regular inspections using our Preventive Maintenance Checklist help identify wear-and-tear, needed adjustments, or replacements. By enrolling in our Preventive Maintenance Program, you can reduce downtime and extend equipment life with scheduled site visits and corrective actions.

Download Our Preventive Maintenance Checklist

Your safety challenges deserve more than a one-size-fits-all fix.

We take the time to understand your machines, your team, and your goals to deliver custom guarding systems that work with your operations, not against them.