Introduction

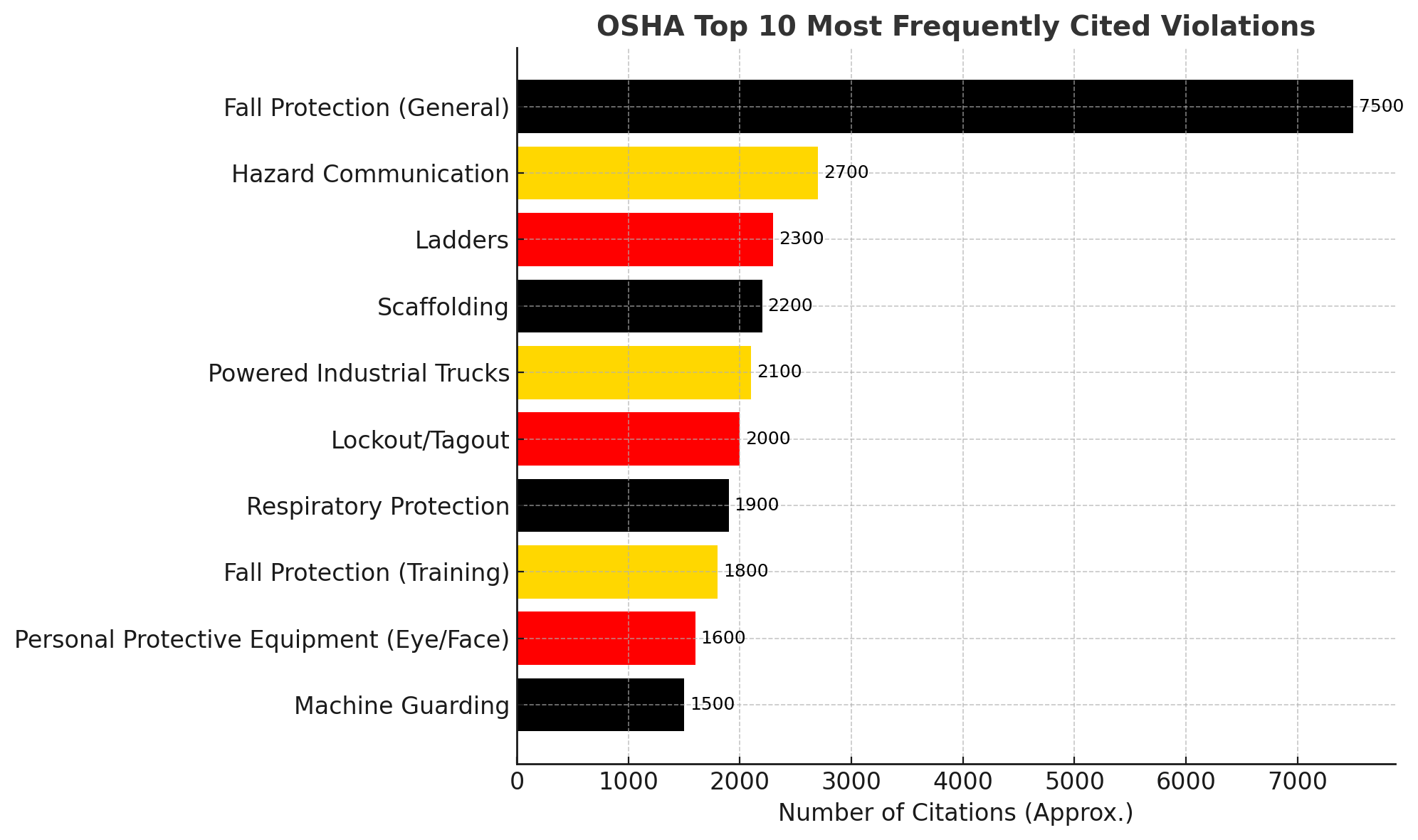

Machine guarding is one of the most fundamental safety measures in any manufacturing or industrial environment. Guards, barriers, and interlocks protect workers from hazards such as rotating parts, flying chips, sparks, and pinch points. Despite their importance, OSHA (Occupational Safety and Health Administration) continues to rank machine guarding among the Top 10 most frequently cited violations every year.

So, what happens if an OSHA inspection reveals that your facility has a machine guarding violation? The short answer: penalties, citations, reputational damage, and possible legal consequences—but also an opportunity to improve your safety culture.

In this article, we will break down what you can expect during an OSHA inspection, the immediate and long-term impacts of a violation, and most importantly, how to protect your workforce and stay compliant.

Why OSHA Focuses on Machine Guarding

Machine-related injuries can be catastrophic. According to OSHA, amputations, crushed hands, severe lacerations, and fatalities are all common outcomes of unguarded or improperly guarded machines. The agency prioritizes machine guarding enforcement because:

- High-risk of injury: Thousands of amputation and entanglement incidents are reported every year.

- Clear standards exist: OSHA regulation 29 CFR 1910.212 provides explicit requirements for machine guarding.

- Preventability: Professionally installed and maintained guards almost always eliminate or drastically reduce risks.

When OSHA inspectors walk into a facility, machine guarding issues are one of the first things they look for because violations are easy to spot and carry severe consequences for worker safety.

How an OSHA Inspection Works

Before we get into the consequences, let us quickly cover the inspection process. OSHA inspections are typically unannounced and can be triggered by:

- Employee complaints

- Referrals from other agencies

- A severe injury or fatality report

- A programmed inspection targeting high-risk industries

Once on-site, an OSHA compliance officer (CSHO) will:

- Conduct an opening conference: Explain why they are there.

- Walk around your facility: Observe workstations, take photos, and talk to employees.

- Focus on machine safety: Look for missing guards, bypassed interlocks, unsafe practices.

- Hold a closing conference: Share initial findings and next steps.

If a machine guarding violation is found, the CSHO will document it thoroughly. This is where the real consequences begin.

What Happens When OSHA Finds a Violation

1. You Receive a Citation

If OSHA determines that your facility is in violation of machine guarding standards, you will receive a written citation. This will outline:

- The specific OSHA standard violated (e.g., 1910.212)

- A description of the hazardous condition

- The classification of the violation

- The deadline to correct the hazard (abatement date)

- Potential penalties

2. Violation Classification Matters

Not all violations carry the same weight. OSHA classifies them based on severity and employer knowledge:

- Other-Than-Serious: A safety issue exists but is not likely to cause death or serious injury.

- Serious: A hazard that could cause serious injury or death, and the employer should have known about it.

- Willful: The employer knowingly failed to comply or acted with plain indifference to safety.

- Repeat: A violation that has been cited previously within the past 5 years.

- Failure to Abate: The employer did not fix a previously cited violation by the deadline.

Machine guarding violations are always classified as Serious, but if OSHA believes you knowingly ignored the problem, it could be elevated to Willful…which carries far steeper consequences.

3. Financial Penalties Are Assessed

As of 2025, OSHA penalties are approximately:

- Serious and Other-Than-Serious: Up to $16,131 per violation

- Failure to Abate: Up to $16,131 per day past the abatement date

- Willful or Repeat: Up to $161,323 per violation

These fines can add up quickly, especially if multiple machines are cited. A single unguarded lathe or press brake could trigger tens of thousands of dollars in penalties.

4. Reputational and Legal Risks

Beyond fines, citations become public record and are posted on OSHA’s website. This can affect your company’s reputation with employees, customers, and potential partners. In extreme cases where willful negligence leads to a fatality, criminal charges may even be pursued against company leadership.

5. Required Abatement and Proof of Correction

You’ll be required to fix the violation by the abatement date provided in the citation. This may involve:

- Installing guards or interlocks

- Updating lockout/tagout procedures

- Retraining employees on safe use of machinery

OSHA will require proof of correction, such as photographs, invoices, or safety reports. Failure to provide adequate documentation can trigger additional penalties.

Real-World Examples of Machine Guarding Citations

To understand the seriousness, let us look at some real-world cases:

- Food Processing Plant: OSHA fined a facility over $100,000 for repeated violations after multiple workers suffered amputations on unguarded equipment.

- Metal Fabrication Shop: A shop was cited for not guarding grinders and received a Serious violation fine of $15,000.

- Packaging Manufacturer: A repeat machine guarding violation resulted in a six-figure penalty and increased scrutiny from OSHA for years.

These examples highlight that ignoring machine guarding is not just dangerous, but it is expensive.

The Bigger Picture: Impact on Business Operations

An OSHA citation is more than a fine…it can disrupt your entire operation. Here is how:

- Downtime: Machines may need to be shut down until properly guarded.

- Insurance premiums: Worker’s compensation and liability insurance rates often rise after citations.

- Employee morale: Workers may feel unsafe or distrust leadership.

- Increased inspections: Once cited, OSHA may return more frequently to check compliance.

In short, the cost of non-compliance often far outweighs the cost of installing proper guards in the first place.

How to Prevent a Machine Guarding Citation

1. Conduct Regular Risk Assessments

A proactive risk assessment helps identify potential hazards before OSHA does. Evaluate all machinery for pinch points, rotating parts, flying debris, and other hazards.

2. Install Proper Guards and Devices

Use fixed barriers, interlocked guards, light curtains, or two-hand controls where appropriate. Make sure guards cannot be easily bypassed.

3. Maintain and Inspect Guards Frequently

Broken, missing, or removed guards are a major red flag for OSHA. Implement a preventive maintenance schedule to keep safety devices in place and working.

4. Train Employees on Safe Practices

Even the best guards will not help if employees do not know how to use them. Provide training on:

- Why guards are essential

- How to safely operate machinery

- What to do if a guard is damaged or missing

5. Create a Safety-First Culture

Encourage employees to report safety concerns without fear of retaliation. OSHA takes employee complaints seriously, and fostering a proactive culture can prevent citations.

What To Do If You are Cited for a Violation

- Do not Panic: Take the citation seriously but respond professionally.

- Review the Citation Carefully: Understand the exact violation and standard referenced.

- Correct the Hazard Immediately: Even if you plan to contest the citation, fix the issue right away to protect employees and demonstrate good faith.

- Decide Whether to Contest: Employers have the right to contest citations if they believe they are unjustified. However, this requires strong documentation and legal counsel.

- Document Everything: Keep thorough records of corrective actions, training, and communications with OSHA.

Long-Term Benefits of Compliance

While the fear of fines motivates many companies to take machine guarding seriously, the true value lies in protecting your workforce. Companies that invest in safety benefit from:

- Fewer injuries and lower medical costs

- Higher productivity due to fewer disruptions

- Stronger employee trust and retention

- A competitive advantage when bidding for contracts with safety-conscious customers

In other words, machine guarding is not just compliance…it is good business.

Conclusion

If an OSHA inspection reveals a machine guarding violation, your company faces more than just a fine. You will be dealing with citations, possible repeat inspections, operational disruptions, and lasting reputational impacts. But it is also a wake-up call—an opportunity to strengthen your safety systems and protect your most valuable asset: your people.

By staying proactive with risk assessments, installing proper guards, and fostering a culture of safety, you can avoid citations altogether and create a workplace where employees feel confident and protected.

Remember: OSHA compliance is not just about avoiding penalties, but about preventing life-changing injuries and ensuring every worker goes home safe at the end of the day.

You can use the Gotcha Stick to verify that machine openings are compliant with OSHA and ANSI Standards.