Introduction: Why This Question Matters

When you step onto a busy factory floor, the hum of machinery, the rhythm of production lines, and the precision of automation all tell the story of modern manufacturing. But alongside this efficiency lies a critical question: what machine tool in a factory environment is the most dangerous for operators to work on?

It is a question every safety manager, plant supervisor, and machine operator should care about. While every piece of equipment poses unique hazards, some machines consistently top the list of dangers due to the way they operate, the speed at which they run, and the severe consequences of misuse or lack of proper guarding.

This blog takes a deep dive into the risks of different machine tools, why certain ones are statistically and practically more dangerous, and, most importantly, what proactive safety measures can turn these hazards into manageable risks.

Section 1: Understanding Machine-Related Hazards

Before identifying the “most dangerous” machine, it is important to understand how machine hazards develop in the first place.

The OSHA Top 10 Most Frequently Cited Violations regularly includes machine guarding violations, underscoring that many injuries are preventable. Hazards usually fall into several categories:

- Point of operation hazards – where cutting, shaping, pressing, or drilling occurs.

- Power transmission hazards – gears, belts, pulleys, shafts, and rotating parts that can catch clothing or fingers.

- Other moving parts – including feed mechanisms, flywheels, and reciprocating components.

The severity of injury risk depends on two things:

- The force and speed of the machine operation

- The likelihood of operator exposure to those hazards

With that in mind, let us explore the most dangerous machine tools you will find in factory environments.

Section 2: The Contenders – Machines with High Injury Risks

1. Mechanical Power Presses

Mechanical presses are widely used in metal forming, stamping, and assembly operations. They exert enormous force, often in the range of several tons, on each stroke.

Why they are dangerous:

- The point of operation is often inches away from where an operator feeds or removes material.

- A mistimed move or unguarded press can lead to crushing or amputation injuries.

- According to OSHA, presses are among the leading machines linked to catastrophic injuries.

Safety considerations:

- Two-hand controls or presence-sensing devices (light curtains, laser scanners).

- Fixed or interlocked guards.

- Regular inspections for brake and clutch systems.

2. CNC Machining Centers

CNC machines, mills, lathes, and routers are precision workhorses of manufacturing. While enclosed by design, they still pose significant hazards.

Why they are dangerous:

- Operators often need to load or unload raw material and parts.

- A loose chuck, tool break, or door override can send metal fragments flying.

- Entanglement in rotating spindles or stock can cause severe injury.

Safety considerations:

- Door interlocks and emergency stop devices.

- Preventing operators from bypassing guards.

- Proper PPE, including face shields and cut-resistant gloves.

3. Industrial Press Brakes

Press brakes bend sheet metal and require precise operator positioning. Unlike mechanical presses, the danger zone is often harder to guard effectively due to the bending action.

Why they are dangerous:

- Hands frequently work close to the point of operation.

- Even a slow-moving ram can cause crushing injuries.

- Injuries often happen during setup or adjustment.

Safety considerations:

- Laser guarding systems that monitor hand placement.

- Two-hand controls.

- Training operators to maintain safe clearance zones.

4. Table Saws and Cutting Tools

In wood, plastics, and some light-metal shops, table saws are common but notoriously hazardous.

Why they are dangerous:

- High-speed rotating blades make accidental contact devastating.

- Kickbacks can launch material back at the operator with lethal force.

- Fingers, hands, and arms are most frequently injured.

Safety considerations:

- Blade guards and riving knives.

- Saw-stop or electronic braking technology.

- Push sticks and material supports to keep hands away from blades.

5. Conveyors and Rollers

Conveyors are often overlooked, but they pose crushing and entanglement hazards.

Why they are dangerous:

- Pinch points where belts meet pulleys or rollers.

- Clothing, hair, or jewelry can get entangled pulling operators in.

- Crushing risks exist when working near transfer points or heavy loads.

Safety considerations:

- Emergency pull cords.

- Physical guarding around rollers.

- Strict lockout/tagout procedures for maintenance.

Section 3: Which Machine Is the Most Dangerous?

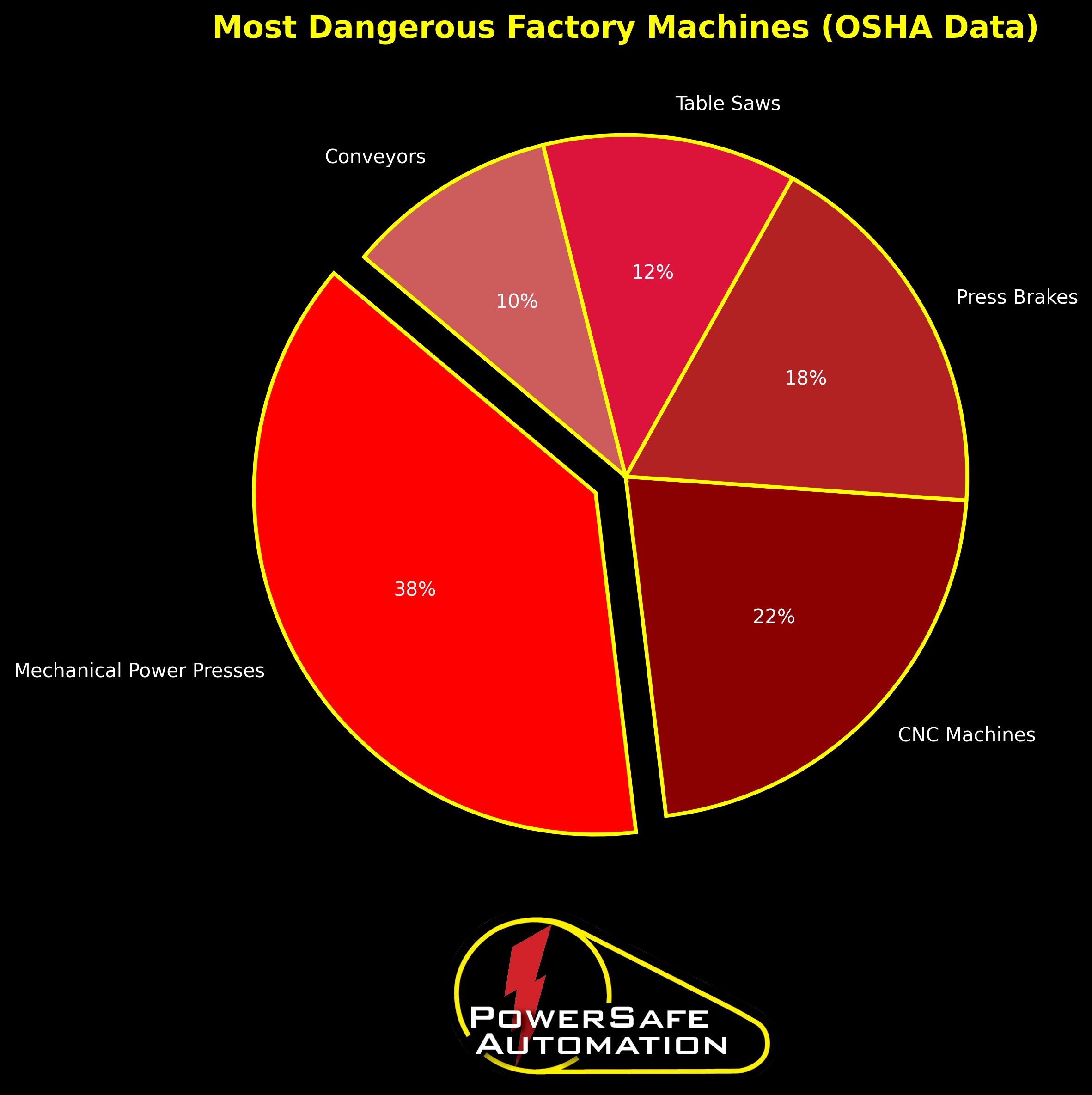

After reviewing the risks, most safety experts, and regulatory data point to mechanical power presses as the single most dangerous machine tool in a factory environment.

Here is why:

- The force output is extremely high—capable of severing limbs instantly.

- The point of operation is small and precise, making it tempting for operators to use their hands to align or adjust material.

- OSHA and NIOSH injury data consistently link presses to high rates of amputation and severe injuries compared to other machine categories.

- Many presses in use today are legacy machines, lacking modern safeguarding systems.

That said, context matters. In some plants, press brakes, saws, or CNCs may be the most hazardous based on volume of use, operator interaction, and guarding effectiveness.

Section 4: The Role of Safety Culture and Human Behavior

Even the most dangerous machines can be made safer with the right systems and culture. Unfortunately, many accidents stem from:

- Operators bypassing guards “to get the job done faster.”

- Lack of training on proper machine use.

- Inconsistent lockout/tagout practices during maintenance.

- Production pressure overriding safety protocols.

This is why safety managers must focus on behavioral safety and cultural reinforcement, not just compliance. A well-guarded press is useless if workers disable the light curtain to speed up cycle times.

Section 5: Best Practices for Managing High-Risk Machines

1. Conduct Risk Assessments

Every machine should undergo a risk assessment to identify hazards, rank their severity, and prioritize corrective actions. Using frameworks like RRPP (Recognize, Rank, Prioritize, Plan) ensures no hazard goes unnoticed.

2. Invest in Modern Safeguards

- Light curtains and laser scanners detect operator presence.

- Two-hand controls ensure both hands are out of the hazard zone.

- Fixed guards prevent accidental contact.

3. Prioritize Lockout/Tagout

Many catastrophic injuries happen during maintenance. A strict LOTO program saves lives by ensuring machines are fully de-energized before servicing.

4. Emphasize Training and Awareness

Operators must not only know how to run a machine but also understand the risks. Hands-on safety training, refreshers, and signage can make a difference.

5. Build a Safety-First Culture

Leadership must communicate that safety takes priority over speed. Rewarding safe behavior, addressing near-misses, and modeling compliance at all levels are crucial steps.

Section 6: Emerging Technology in Machine Safety

The future of factory safety lies in automation and smart safety devices.

- Collaborative robots (cobots): Designed to safely interact with humans.

- AI-enabled vision systems: Detect unsafe behaviors and trigger machine stops.

- Predictive analytics: Maintenance alerts reduce risks of unexpected breakdowns.

- Ergonomic tooling: Reduces repetitive strain and awkward movements.

These technologies do not replace fundamental guarding but add layers of protection.

Section 7: Turning the “Most Dangerous” Into the “Safest Possible”

It is not enough to identify which machine is the most dangerous. The real challenge, and opportunity, is transforming these risks into manageable, controlled operations.

Safety managers who approach the issue with a holistic strategy, combining engineering controls, administrative controls, PPE, and culture can turn even a mechanical press into a safe, productive asset.

Conclusion: The Takeaway for Safety Leaders

So, what is the most dangerous machine tool in a factory environment? By most measures, the mechanical power press earns that title due to its force, frequency of use, and history of catastrophic injuries.

But the bigger truth is this: any machine without proper safeguarding and operator training can become the most dangerous tool in the facility.

For safety managers, plant engineers, and executives, the responsibility is clear. The path forward requires:

- Investing in risk assessments and modern guarding solutions.

- Training workers to respect machine hazards.

- Building a culture where safety is non-negotiable.

With these steps, the answer to the original question becomes less about fear and more about opportunity…opportunity to lead, protect, and continuously improve the factory floor.