One Source. Total Control: Powering Safer, Smarter Factories with PowerSafe Automation

In the competitive world of manufacturing, companies can no longer afford the inefficiencies and risks of managing multiple vendors for safety, automation, and production needs. Downtime, miscommunication, and conflicting solutions not only eat into profits but also jeopardize operator safety and regulatory compliance.

That’s why more companies are turning to PowerSafe Automation—your single-source partner for premium, turnkey machine safety systems and flexible manufacturing solutions.

By consolidating safety upgrades and automation enhancements through one expert provider, manufacturers gain the power to standardize, scale, and succeed—across machines, departments, and facilities.

The Problem with Fragmented Vendors

Many manufacturers unknowingly rely on a patchwork of service providers for machine safety, automation retrofits, guarding, sensors, and programming. While this may appear cost-effective at first, it often leads to:

-

Conflicting system integrations

-

Inconsistent safety protocols

-

Unclear accountability

-

Delays from vendor handoffs

-

Hidden compliance gaps

With legacy machines and fast-changing production demands, the need for streamlined project execution and consistent engineering support has never been greater.

The PowerSafe Solution: One Partner. One Plan. One Platform.

PowerSafe Automation eliminates the vendor chaos by offering premium machine guarding, automation, risk assessment, and production optimization services—all under one trusted umbrella.

Here’s how we help manufacturers build safer, more agile operations:

1. Complete Turnkey Machine Safety Systems

At PowerSafe, safety isn’t an afterthought—it’s built into every project from day one. Our turnkey machine safety solutions include:

-

Risk Assessments (ANSI/ISO/OSHA-compliant)

-

Custom Machine Guarding (Modular or Tailored)

-

Safety Interlocks, Light Curtains, and Area Scanners

-

Control Reliability and E-Stop Circuit Design

-

Functional Safety Engineering

-

Validation and Documentation Packages

We partner with safety managers, EHS directors, and plant engineers to reduce risk without disrupting productivity.

Our proprietary approach—Recognize, Rank, Prioritize, Plan (RRPP)—allows us to evaluate all equipment on-site and guide clients in creating a 12-month safety improvement roadmap.

2. Flexible Manufacturing Solutions for Evolving Needs

Beyond safety, we help you enhance output and consistency through modular automation:

-

Automated Material Handling

-

Poka-Yoke Error Proofing

-

End-of-Line Test Fixtures

-

Custom Part Fixturing and Staging

-

Continuous Flow Conveyor Systems

These flexible solutions are plug-and-play ready, designed to integrate with your existing machinery or new equipment—with full electrical, mechanical, and programming support.

Whether you're retrofitting legacy equipment or launching a new line, our solutions adapt as your needs evolve.

Why Single-Source Integration Beats Multi-Vendor Chaos

Choosing a single-source partner like PowerSafe Automation provides major advantages across your entire operation:

1. Streamlined Project Management

No more juggling vendors, quotes, and change orders. PowerSafe handles design, procurement, installation, and validation—start to finish.

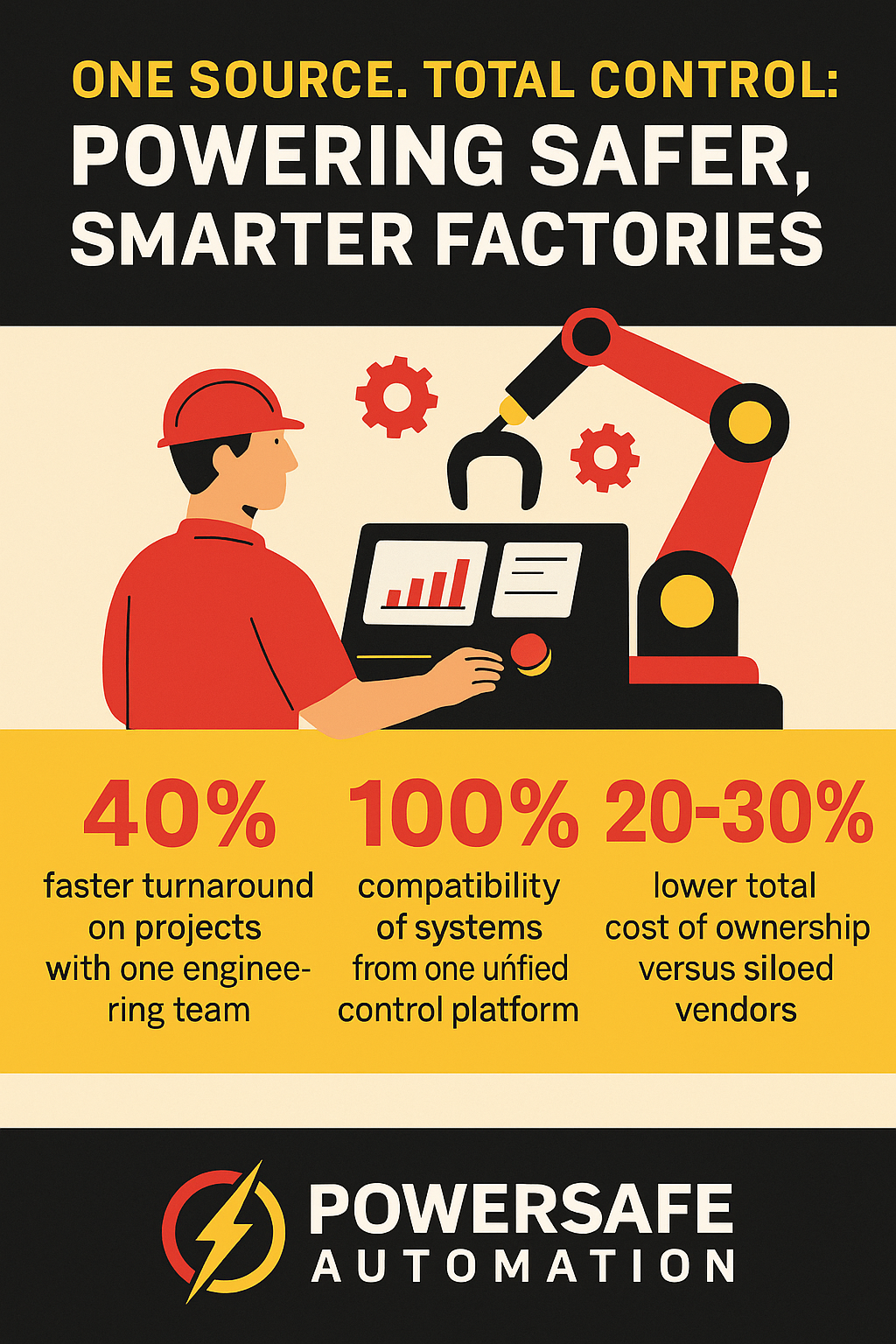

2. Faster Turnaround

With one engineering team, we cut delays between stages of design, fabrication, and install. Projects move forward without waiting on third-party availability.

3. Guaranteed Compatibility

All systems—from guarding to cobots to conveyors—are designed to work together seamlessly under one unified control platform.

4. Improved Compliance

By following ANSI B11, OSHA 1910.212, and ISO 13849-1 standards at every stage, we ensure documentation and validation meet audit and insurance requirements.

5. Lower Total Cost of Ownership

Avoid repeat retrofits, rework, and downtime. Our premium solutions are built for longevity, with modular components that can be reused or reconfigured as your facility changes.

Real-World Impact: Consolidated Success Across Industries

PowerSafe Automation proudly serves clients in a variety of industries, including:

-

Industrial Motion Products – Safe retrofit of press brakes, conveyors, and rotating shafts.

-

Wire & Cable – Fully guarded extrusion lines with automated take-up and safety interlocks.

-

Insulation & Construction Materials – Guarding and cobot integration for roll handling and wrapping.

-

Food & Beverage – Stainless guarding, automation, and safety control validation.

-

Packaging & Corrugated – Modular guarding systems and collaborative robots on flexo lines.

These companies aren’t just meeting compliance—they’re leading the charge on operational excellence, supported by a single partner from concept to commissioning.

Built for Multi-Facility Manufacturing Groups

For large manufacturing networks, vendor standardization is critical.

PowerSafe Automation is equipped to:

-

Implement facility-wide risk assessments

-

Develop standardized guarding and automation packages

-

Roll out consistent safety documentation across plants

-

Provide ongoing support for retrofits, audits, and upgrades

Whether you have five facilities or fifty, we help corporate safety and engineering leaders align local operations under one strategic vision.