Introduction: Why Manual Lathe Safety Matters

If you walk into almost any machine shop or toolroom, chances are you will find a manual lathe quietly sitting in the corner. Despite the rise of CNC machining and automated systems, manual lathes remain a trusted workhorse. They are durable, versatile, and cost-effective. But they are also among the most dangerous machines if not managed with respect.

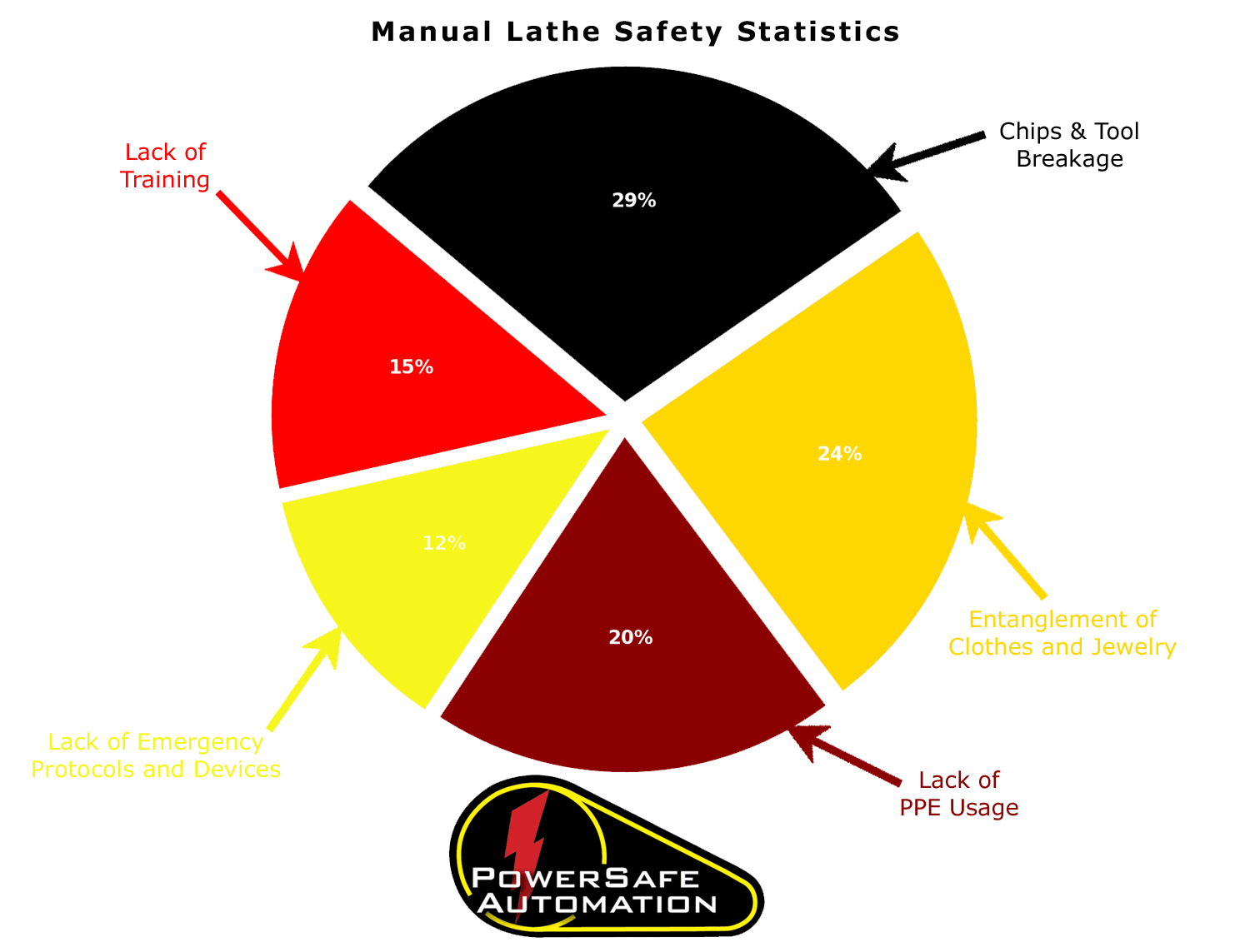

The rotating chuck, sharp cutting tools, and high torque involved in lathe operations create plenty of opportunities for serious injuries. Entanglement accidents, flying chips, and tool breakage are common risks. In fact, OSHA, and ANSI both cite lathes as machines that require strict safety precautions.

So, what should machinists, toolmakers, and students keep in mind when using a manual lathe? In this blog, we will walk through essential safety precautions—from personal protective equipment to operational best practices—so you can run a manual lathe with confidence and avoid costly accidents.

1. Dress for Safety: The Right PPE and Clothing

Before you even step up to the machine, what you are wearing plays a huge role in your safety.

- Eye protection: Always wear ANSI-approved safety glasses with side shields. Manual lathes produce chips that can travel at high speeds, and one stray piece of hot metal can cause permanent eye damage.

- Face shield: For heavy roughing cuts or high-chip applications, it is recommended adding a clear face shield over your glasses.

- Hearing protection: Manual lathes are not always as loud as CNC machines, but sustained noise exposure in a shop environment can still lead to hearing loss. Earplugs or earmuffs are a good precaution.

- Clothing: Loose sleeves, dangling jewelry, neckties, or unbuttoned collars are an invitation for entanglement. Always wear snug-fitting clothing and secure long sleeves above the elbow.

- Footwear: Steel-toe or composite-toe boots are the best choice. They protect against dropped workpieces, wrenches, or chuck jaws.

- Gloves: This one can be tricky. Gloves protect against sharp chips when cleaning but never wear gloves while the machine is running. The risk of entanglement outweighs the protection. Use a brush to clear chips instead.

The bottom line: dress as if you expect the unexpected. PPE is your first line of defense when things go wrong.

2. Inspect the Lathe Before Use

Even experienced machinists sometimes skip this step, but pre-operation checks are crucial. A worn-out chuck, missing guard, or damaged tool post can set the stage for an accident.

- Check the power switch: Ensure it is in good working order. Emergency stops should be clearly marked and easy to reach.

- Inspect the chuck and jaws: Make sure the workpiece grips securely and that no chips are jammed in the serrations.

- Look for missing or damaged guards: OSHA requires lathe chucks and rotating components to be guarded when practical.

- Check lubrication and oil levels: A dry spindle bearing can cause overheating, vibration, or sudden failure.

- Examine cutting tools: A dull tool not only ruins your part but can also grab and break underload, sending shards across the shop.

Spending a few minutes on inspection is far cheaper than dealing with downtime, injuries, or scrapped material.

3. Understand the Machine’s Capabilities and Limits

Not all lathes are created equally. A small toolroom lathe is not designed for the same heavy-duty cuts as a large engine lathe. Exceeding the machine’s limits can cause crashes, tool breakage, and even catastrophic failure.

- Know the spindle speed range: Never exceed the recommended surface feet per minute (SFM) for the material you are cutting.

- Respect horsepower ratings: A smaller machine will not handle deep cuts in tough alloys.

- Stay within workholding limits: If your part is too large for the chuck or extends too far without support, use a steady rest, tailstock center, or larger lathe.

- Follow the operator’s manual: Every machine has unique controls and safety warnings.

Understanding your machine’s envelope not only prevents damage but also improves cut quality and tool life.

4. Workholding Safety: Secure the Part

Workholding is one of the most overlooked aspects of lathe safety. A poorly clamped part can slip, eject, or chatter violently.

- Always tighten the chuck evenly: Use the correct chuck key and never leave it in the chuck.

- Support long stock: Any bar extending past the headstock should be guarded or supported with a bar puller. Unsupported bar stock can whip like a helicopter blade.

- Check tailstock alignment: For longer parts, bring up the tailstock center to prevent deflection and vibration.

- Avoid handholding: Never hold a part by hand against the chuck or faceplate. It may seem faster, but it is extremely dangerous.

Think of the chuck as the handshake between the machine and your part—make sure it is solid and reliable.

5. Cutting Tool Safety

Cutting tools are sharp, brittle, and under a lot of stress during operation. Improper handling can lead to injuries or tool failure.

- Mount tools securely: Use the correct tool post and ensure the tool is clamped tightly.

- Set the tool on centerline: An off-center tool increases cutting forces and can snap unexpectedly.

- Use the right tool for the job: A threading tool should not be used for roughing, and a parting tool needs plenty of clearance.

- Keep hands away: Even when stationary, carbide inserts are razor-sharp. Handle with caution.

Sharp tools cut better and safer than dull ones—do not push tools past their usable life.

6. Operational Safety: Running the Lathe

Now we come to the heart of lathe safety: actual operation. This is where awareness and good habits pay off.

- Stand to the side when starting: Chips, coolant, or loose parts can fly straight out when the spindle first turns.

- Never adjust the machine while running: This includes measuring, tightening tools, or adjusting tailstock quills.

- Keep your hands clear: Never try to stop a rotating chuck or spindle with your hands. Wait until it comes to a complete stop.

- Avoid distractions: Do not text, take calls, or carry-on deep conversations while the lathe is spinning.

- Stay with the machine: Never walk away while the spindle is turning, even on long cuts.

Remember: the lathe does not forgive inattention. Respect the rotation, and you will stay safe.

7. Chip and Coolant Safety

Lathe chips are notorious for their sharpness and spring-like curls. Handling them incorrectly is one of the fastest ways to end up in the first-aid room.

- Use a brush or hook: Never use your hands to clear chips, especially near the chuck.

- Beware of hot chips: Some operations throw red-hot spirals of metal. Keep your body and face out of the line of fire.

- Mind coolant splash: Cutting fluids can irritate skin and eyes. Wear gloves when handling coolants but avoid them during cutting.

- Dispose of chips safely: Use designated bins and never leave sharp spirals lying on the floor.

Chip control is not just a housekeeping issue—it is a critical safety precaution.

8. Emergency Preparedness

Despite best practices, accidents can still happen. Knowing how to react quickly can minimize harm.

- Know the emergency stop button: Make sure you can reach it instantly.

- Have first-aid supplies nearby: Every machine shop should have stocked kits within easy reach.

- Train for fire safety: Cutting oils and coolant can ignite under extreme conditions. Know where extinguishers are located.

- Communicate: If you are a student or apprentice, never hesitate to call for help if something feels wrong.

Preparedness is not pessimism, it is professionalism.

9. Training and Supervision

For new machinists, supervision and training are as important as PPE. Even experienced toolmakers benefit from refresher training.

- Follow OSHA and ANSI standards: These provide baseline safety requirements for lathe operation.

- Seek mentorship: Learning from seasoned machinists shortens the learning curve and helps you avoid bad habits.

- Encourage a safety culture: Supervisors should reward safe practices, not just fast output.

A shop that invests in training reduces accidents, improves morale, and often sees better productivity.

10. Common Mistakes to Avoid

Let us close with a few all-too-common mistakes that lead to preventable injuries:

- Leaving the chuck key in the chuck.

- Wearing gloves, jewelry, or long sleeves.

- Attempting to measure parts while the spindle is turning.

- Overreaching near the rotating workpiece.

- Using makeshift workholding instead of proper fixturing.

- Forgetting to remove the tool when reversing the spindle.

Avoiding these mistakes can make the difference between a productive day and a trip to the emergency room.

Conclusion: Respect the Machine, Protect Yourself

Manual lathes are invaluable in machine shops and toolrooms. They allow for custom one-offs, quick repairs, and precision work that CNC machines sometimes cannot replicate as efficiently. But with that versatility comes risk.

By wearing the right PPE, inspecting your machine, securing workpieces, using sharp tools, and practicing safe operational habits, you drastically reduce the chance of injury. The best machinists are not just skilled at cutting metal, they are skilled at protecting themselves and those around them. Respect the lathe, and it will serve you well for years to come.