Introduction

Safety light curtains are essential components of machine guarding systems in modern manufacturing facilities. They help prevent injuries by creating an invisible barrier that stops dangerous machine movement when breached. Proper installation is critical to ensure both safety and compliance with OSHA and ISO 13855 standards.

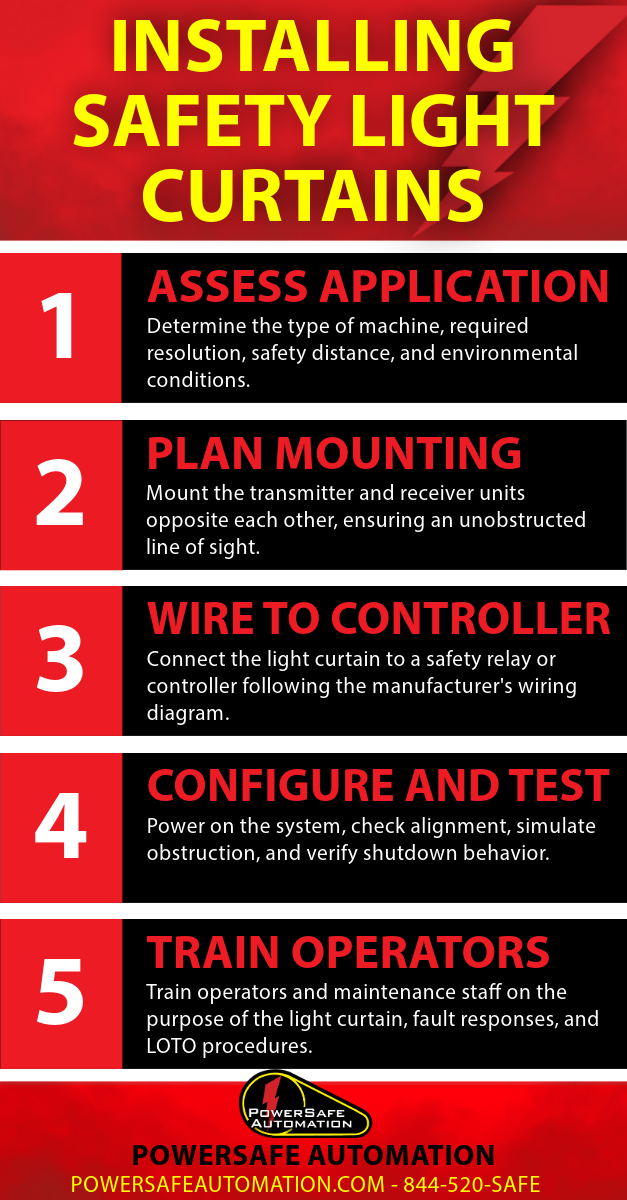

This guide walks you through the process of installing safety light curtains—from preparation to testing—to help you reduce downtime and improve workplace safety.

Step 1: Assess the Application and Choose the Right Light Curtain

Key Considerations:

- Type of machine (e.g., press, robotic cell, conveyor)

- Required resolution (finger, hand, or body detection)

- Safety distance requirements

- Environmental conditions (temperature, dust, vibration)

Pro Tip: Refer to ISO 13855 to calculate the required safety distance based on machine stop time and light curtain response time.

Step 2: Plan the Mounting Locations

- Transmitter and receiver units must be mounted opposite each other, aligned precisely.

- Ensure unobstructed line of sight across the full length.

- Mount at the correct height from the floor—typically between 300 mm and 1200 mm depending on the risk level and resolution.

Avoid: Mounting in areas where reflective surfaces could create false signals.

Step 3: Mount the Light Curtain Hardware

- Install brackets securely on the machine frame or guarding structure.

- Mount the transmitter and receiver units.

- Use a spirit level or laser alignment tool to ensure they’re precisely aligned.

Important: Use vibration-resistant mounts if the equipment is subject to frequent movement or shock.

Step 4: Wire the Light Curtains to the Safety Controller

- Follow the manufacturer’s wiring diagram.

- Connect to a Category 3 or 4 safety relay or controller.

- Ensure all emergency stop functions are integrated.

Note: Incorrect wiring can result in failed risk reduction or false positives.

Step 5: Configure and Test the System

- Power on the system and check alignment indicators.

- Simulate obstruction to test shutdown behavior.

- Verify muting, blanking, or override functions if applicable.

- Document the stop time measurement and verify safety distance.

OSHA Tip: Keep records of installation and test procedures for audits.

Step 6: Train Operators and Finalize Documentation

- Train operators and maintenance staff on:

- The purpose of the light curtain

- How to respond to faults or trips

- Include the light curtain in your Lockout/Tagout (LOTO) procedures.

- Update your machine risk assessment and maintenance documentation.

Final Thoughts

Correct installation of safety light curtains is critical for compliance and injury prevention. Regular inspections, maintenance, and operator training help ensure your system remains effective. For best results, partner with certified safety engineers and consult your machine’s OEM before installation.

To listen to the video on this Installing Safety Light Curtains blog