How to Prove Machine Guarding ROI to Plant Management: A Safety Manager’s Guide

In manufacturing, safety isn't just a compliance issue—it's a strategic business decision. But as any safety manager knows, securing buy-in from upper management for machine guarding upgrades often requires more than a safety-first mindset. You need to make a solid financial case that resonates with executives.

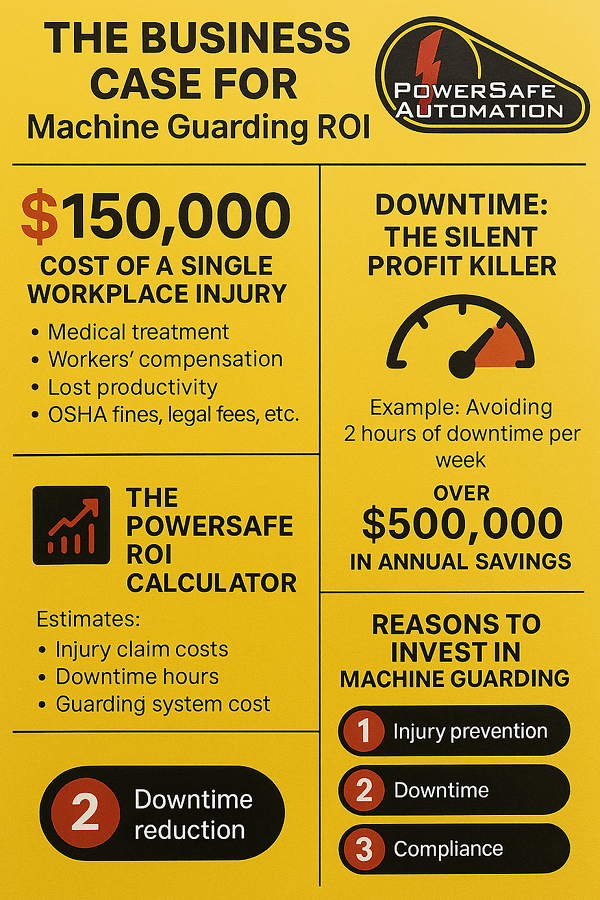

If you’re wondering how to justify a guarding project to upper management, this guide will walk you through how to turn machine safety into measurable return on investment (ROI). We’ll explore how to quantify the cost of injuries and downtime, and how tools like the Power Safe Automation ROI Calculator can help make your business case bulletproof.

Why Proving ROI for Machine Guarding Is Essential

When you’re responsible for both worker safety and production efficiency, the value of machine guarding seems obvious. But for senior executives and plant managers focused on budgets and quarterly performance, safety upgrades can look like just another expense.

That’s where proving machine safety ROI comes in. By shifting the conversation from cost to cost avoidance, you reframe machine guarding as a proactive investment in operational reliability and risk mitigation.

The Real Cost of Workplace Injuries

It’s easy to underestimate the financial impact of a single workplace injury. But the numbers tell a different story.

According to OSHA, a serious workplace injury can cost upwards of $150,000 when you include both direct and indirect expenses:

-

Medical treatment

-

Workers’ compensation

-

Lost productivity

-

Equipment repairs

-

OSHA fines

-

Legal settlements

-

Damage to company reputation

Now consider this: If one machine guard prevents even a single serious injury, it could cover the cost of multiple safety upgrades. That’s the power of ROI-focused safety planning.

Downtime: The Silent Profit Killer

Unplanned downtime is another hidden cost that many decision-makers underestimate. Every minute of lost production translates into wasted labor, missed delivery deadlines, and operational chaos.

Unguarded machines are more likely to be bypassed or malfunction, creating safety hazards that often result in unplanned production halts. Even brief interruptions can accumulate into significant costs over time.

Example:

Avoiding just 2 hours of downtime per week at a facility with $5,000/hour productivity rates can result in over $500,000 in annual savings.

Investing in machine guarding isn’t just about compliance—it’s about safeguarding uptime and ensuring continuous productivity.

Introducing the Power Safe ROI Calculator

At Power Safe Automation, we’ve developed a Machine Guarding ROI Calculator designed to help safety managers translate safety improvements into real financial metrics.

This free tool helps you estimate:

-

The average cost of injury claims at your facility

-

Frequency of near-misses or past incidents

-

Downtime hours related to unguarded equipment

-

Labor and productivity losses per hour

-

Estimated cost of the guarding system

With this data, the calculator provides a clear ROI estimate—turning your safety proposal into a persuasive business case for upper management.

Speaking the Language of Management: Cost Avoidance

Executives often see safety upgrades as necessary evils or unavoidable costs. Your job is to flip that perception by focusing on cost avoidance—what the business saves by investing in machine guarding.

Key ROI Talking Points:

-

Injury prevention: Avoiding just one serious injury can save over $150,000.

-

Downtime reduction: Reducing equipment-related downtime saves both labor and opportunity costs.

-

Insurance savings: Lower incident rates may lead to reduced premiums.

-

Fines and penalties: OSHA violations can result in hefty fines and legal costs.

-

Employee morale: A safer work environment reduces turnover and increases engagement.

When framed this way, a guarding project becomes an investment with a payback period—often less than 12 months—not a sunk cost.

5 Steps to Justify a Guarding Project to Plant Management

Making a successful pitch to leadership requires more than passion—it requires preparation, data, and strategy. Here’s a step-by-step plan to help you make your case.

1. Gather the Right Data

Start by collecting safety and operational records:

-

Injury logs

-

OSHA incident reports

-

Downtime tracking

-

Maintenance tickets

-

Audit findings

The more data you have, the more compelling your argument becomes.

2. Quantify the Risks

Use the Power Safe ROI Calculator to estimate the cost of:

-

Historical and potential injury incidents

-

Lost production hours

-

Equipment downtime

This quantification helps translate abstract risks into concrete financial numbers.

3. Present Scalable Options

Management appreciates flexibility. Propose phased implementation plans or scalable solutions that fit within budget cycles or capital expenditure limits.

This makes your proposal easier to accept and approve.

4. Speak in Outcomes

Avoid overly technical jargon. Instead, focus on business outcomes:

-

"We can reduce risk exposure by 80%."

-

"This solution offers a 10-month payback period."

-

"We estimate a $220,000 cost avoidance in year one."

Let the benefits drive the conversation.

5. Show the ROI

Close your case with a simple ROI summary:

-

Initial investment

-

Estimated savings

-

Payback period

-

Long-term operational benefits

Include charts or visuals to help tell the story. Numbers speak loudly in boardrooms.

Real-World Impact: A Success Story

One of our clients—a Midwest manufacturing company—used the PowerSafe ROI Calculator to evaluate a full machine guarding upgrade.

Key findings before the project:

-

Recurring minor injuries

-

30-minute average downtime per safety incident

-

Operator bypasses were common

Results after implementation:

-

Injury-related costs dropped to zero

-

Downtime incidents cut in half

-

Over $220,000 in avoided costs in the first year

Just as importantly, the company noticed improved employee morale and confidence on the shop floor. When workers feel safe, productivity often follows.

Machine Guarding and Compliance: More Than a Checklist

While ROI is a powerful justification, don’t forget the regulatory landscape. OSHA requires that machines be properly guarded to protect operators from hazards.

Failure to comply can lead to:

-

Costly fines

-

Legal liability

-

Injunctions or shutdowns

-

Public reputation damage

By investing proactively, you not only avoid compliance risks but also demonstrate that your company takes worker safety seriously.

Let Power Safe Help You Build Your Case

At Power Safe Automation, we specialize in helping safety managers turn compliance needs into strategic investments.

We can assist you with:

-

Conducting a machine risk assessment

-

Estimating potential cost savings

-

Generating ROI projections

-

Selecting the right guarding technologies

Whether you’re in the early stages of a safety initiative or preparing for a boardroom pitch, our team is here to help.

Safety Isn’t a Cost—It’s a Strategic Advantage

If your company values uptime, workforce retention, and operational excellence, then machine guarding is not optional—it’s essential.

By focusing on ROI, cost avoidance, and business continuity, you can elevate safety from a line item to a strategic advantage.

Ready to Justify a Guarding Project to Upper Management?

Don’t go into the next budget meeting empty-handed. Use the PowerSafe Automation Machine Guarding ROI Calculator to build a case that speaks their language—and protects your workforce.

Contact us today or try our Machine Guarding ROI Calculator to get started.