Enhancing Industrial Efficiency: How Custom Transfer Tables and Workflow Stations Drive Lean Manufacturing Success

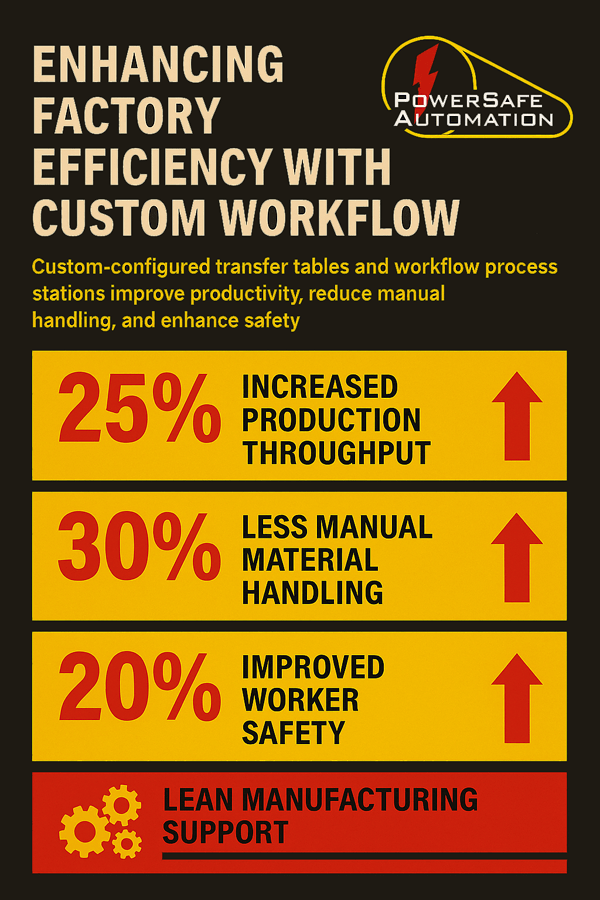

In the fast-paced and increasingly competitive landscape of industrial manufacturing, operational efficiency isn't just a goal—it's a requirement for survival. A streamlined workflow can make the difference between a factory that thrives and one that struggles with downtime, missed deadlines, and safety hazards. In modern factories, the implementation of custom-configured transfer tables and workflow process stations is a game-changing strategy to boost productivity, reduce manual handling, and elevate workplace safety.

Whether you’re managing an automotive assembly line, food packaging plant, or high-volume electronics manufacturer, integrating ergonomic, modular workflow tools helps ensure the smooth, continuous movement of materials. Let’s explore how these solutions fit into a lean manufacturing strategy—and how trusted partners like PowerSafe Automation can help optimize your operations.

Why Efficient Workflow is Crucial in Industrial Factories

A well-designed workflow forms the backbone of a productive factory. When materials, information, and tasks flow smoothly from one step to the next, it reduces delays, minimizes errors, and ensures that all resources—human and mechanical—are being used efficiently.

Key Benefits of a Structured Workflow:

-

Increased Throughput: Smooth material movement prevents bottlenecks and keeps lines running at full capacity.

-

Reduced Downtime: Predictable workflows reduce the need for rework, troubleshooting, or unplanned maintenance.

-

Higher Safety Standards: Organized processes reduce clutter, minimize manual lifting, and lower the risk of injuries.

-

Improved Product Quality: A clean, organized process helps maintain consistent standards and traceability.

-

Better Use of Space and Labor: Resources are allocated strategically, with minimal waste in time or motion.

Unfortunately, many factories still rely on outdated or generic setups that lead to manual handling, inconsistent work patterns, and inefficient transitions between tasks.

Transfer Tables: The Unsung Heroes of Material Handling

Custom-configured transfer tables are a critical tool for optimizing factory layout and material flow. These tables facilitate the seamless transition of parts, materials, or products between workstations, conveyor systems, or assembly areas.

What Are Transfer Tables?

Transfer tables are engineered platforms that can slide, rotate, or pivot materials between work zones. Depending on the design, they may be powered or manual and can be integrated with automation systems or machine guarding.

Benefits of Transfer Tables:

-

Reduces Manual Lifting: Minimizes physical strain on operators, improving ergonomics.

-

Speeds Up Production: Transfers materials faster and with greater precision than manual handling.

-

Adapts to Any Line: Modular configurations accommodate different product sizes and workflows.

-

Supports Lean Principles: Reduces waste by streamlining material movement and minimizing touchpoints.

By reducing unnecessary manual steps and aligning with automation systems, transfer tables are a low-profile but high-impact investment for factories targeting lean efficiency.

Process Workflow Stations: Purpose-Built Efficiency at Every Step

While transfer tables move materials efficiently, process workflow stations ensure that every task—assembly, inspection, testing, packaging—is executed with maximum efficiency and minimal error.

What Are Workflow Stations?

Workflow stations are dedicated zones equipped with the tools, equipment, and ergonomic design needed to complete specific manufacturing tasks. They are typically custom-configured to align with the product type, worker requirements, and safety standards.

Advantages of Custom Workflow Stations:

-

Task Specialization: Supports focused work with all required tools and fixtures within reach.

-

Ergonomic Design: Minimizes worker fatigue and reduces motion waste.

-

Consistent Output: Standardized layouts promote repeatable, high-quality results.

-

Built for Safety: Designed with guarding, lighting, and safety interlocks when needed.

-

Easily Scalable: Modular designs can evolve with changes in production volume or product design.

Process stations create an environment where every second counts—and every motion matters.

How Custom Configurations Drive Results

The key to truly efficient workflows lies in customization. No two factory floors are alike, and no one-size-fits-all solution can account for your product, footprint, and workforce. That’s why top-performing factories turn to custom-configured transfer tables and workflow stations built to their exact needs.

Examples of Custom Configurations:

-

Heavy-Duty Transfer Tables: Designed for oversized automotive components with integrated lift assists.

-

Rotating Tables for Packaging Lines: Allow operators to access different product sides without repositioning.

-

Modular Assembly Workbenches: Adaptable layouts for short production runs or frequent line changeovers.

-

Inline Inspection Stations: Integrate vision systems or sensors for immediate quality control feedback.

-

Height-Adjustable Workstations: Enhance ergonomics for multi-shift operations or varying operator heights.

The Role of Machine Safety in Workflow Optimization

Workflow efficiency isn’t just about speed—it’s also about safety and compliance. Every transfer table and process station must be designed with OSHA, ANSI, and ISO 13849-1 standards in mind to protect workers and ensure regulatory compliance.

Integrated Safety Features May Include:

-

Emergency stop systems

-

Interlocked guarding

-

Presence-sensing devices

-

Zero-speed monitoring

-

Safety PLCs and relays

-

Lockout/tagout (LOTO) zones

When you partner with a solutions provider like PowerSafe Automation, you benefit from integrated systems that combine workflow efficiency and machine safety in one turnkey solution.

Lean Manufacturing and Workflow Efficiency

Custom workflow tools directly support lean manufacturing goals such as reducing waste, improving cycle times, and increasing workplace organization.

Key Lean Principles Supported:

-

Motion: Reduce unnecessary movements with ergonomic station design.

-

Waiting: Eliminate idle time with fast transfer mechanisms.

-

Overproduction: Enable just-in-time (JIT) production with scalable modular systems.

-

Defects: Improve consistency and quality with precise process controls.

-

Inventory: Use real-time flow to limit work-in-progress (WIP) and overstock.

By aligning layout, tooling, and process flow, transfer tables and workstations help build a leaner, more competitive operation.

When Should You Upgrade Your Workflow Setup?

Factories often hesitate to reconfigure their workflows until inefficiencies become costly. However, the following signs indicate it's time to act:

-

Workers frequently stop production to retrieve tools or materials.

-

Material queues form between stations.

-

Manual lifting or awkward motions are common.

-

Quality varies between shifts or operators.

-

The same problems occur repeatedly in audits or inspections.

-

New product introductions take too long to implement.

Proactively addressing these issues with a custom workflow upgrade can lead to substantial improvements in both performance and morale.

Partnering with Power Safe Automation

At PowerSafe Automation, we specialize in helping manufacturing facilities develop safe, efficient, and scalable production environments. Our custom-configured transfer tables, workflow stations, and machine safety systems are engineered to fit your exact needs—no off-the-shelf limitations.

What We Offer:

-

Turnkey factory workflow solutions

-

OSHA/ANSI/ISO-compliant safety systems

-

Modular transfer and material handling systems

-

Ergonomic workstations and operator stations

-

End-to-end design, integration, and support

Our mission is to help your facility work smarter, safer, and faster—delivering ROI through real results.

Final Thoughts: Invest in Workflow to Power Long-Term Success

In today’s industrial landscape, efficiency is not a luxury—it’s a competitive advantage. Factories that invest in custom-configured transfer tables and workflow stations are better positioned to meet customer demands, retain skilled workers, and drive sustainable growth.

Workflow optimization isn’t just about equipment. It’s about creating a culture of continuous improvement—and building systems that support it. Whether you’re planning a new production line or upgrading an existing one, now is the time to prioritize smart workflow solutions.

Ready to Improve Your Workflow?

Connect with Power Safe Automation today to discuss custom solutions for your factory:

- www.powersafeautomation.com

- Email: sales@powersafeautomation.com

- LinkedIn: PowerSafe Automation

- Subscribe on YouTube for safety tips and factory insights

#LeanManufacturing #FactoryEfficiency #MachineSafety #IndustrialAutomation #PowerSafeAutomation