Overview

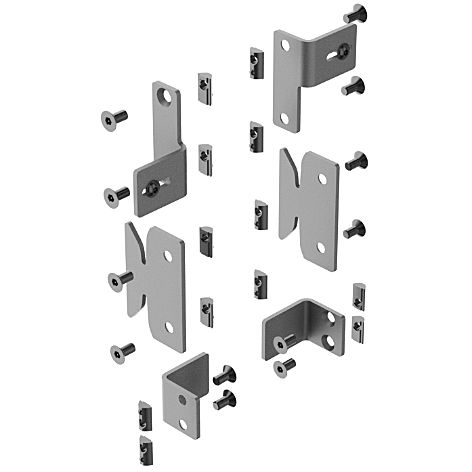

Our removable panel bracket system utilizes FATH’s Safety Hanger 8/8 set (Part # 093WH400808), engineered to provide a quick, secure and compliant method of mounting and removing safety fence or guard panels within machine-safety and automation environments. The system supports profile slot size 8 mm and is designed with a gap distance of 12-26 mm between frame and panel, making it ideal for modular machine-guarding enclosures, access doors and removable safety barriers. +1

Key Features & Benefits

- Rapid removable mounting: The bracket set supports quick removal and re-installation of protective panels, enabling fast access for maintenance or tooling change-over without sacrificing guarding integrity.

- Modular compatibility: Designed for slot size 8 in aluminum profile systems (Profile I) — simplifies integration into existing modular frames. +1

- Robust materials:

- Hanger, supporting hook and supporting angle: steel (zinc-plated)

- Countersunk screws: stainless steel

- T-slot nuts: steel (zinc-plated) +1

- Designed for guard panel spacing: Supports a gap (clearance) of 12-26 mm, enabling proper mounting tolerance while ensuring panel stability. FATH24

- Complete kit for ease of installation: The set includes 2 hangers with safety pin fastening, 2 supporting hooks, 2 supporting angles, 12 M8×16 countersunk screws (DIN 7991) with pin, and 12 T-slot nuts – providing everything needed for two panel anchor points. Easy Systems

- Supports standard compliance: Using quality hardware and defined tolerances helps maintain the robustness of the guarding system, supporting machine safety policies and guarding integrity.

Applications

- Machine-guarding frames where safety fence or mesh panels need to be removed regularly (e.g., for servicing, tooling change, inspection)

- Modifiable enclosures or access doors on production, stamping, robotic or material-handling cells

- Situations where dynamic re-configuration is required (e.g., flexible manufacturing lines) and remountable panels are advantageous

- Upgrades or expansions of existing aluminum profile machine-guarding systems where fast access and re-mounting matter

Installation & Engineering Notes

- Mount the hangers to the profile slot (slot size 8) using the provided T-slot nuts and M8 countersunk screws.

- Ensure the panel gap falls within the 12-26 mm allowance to guarantee proper seating and retention of the hanger system.

- Use the supporting hooks and angles to bear the load of the panel and prevent sag or misalignment when mounted.

- Tighten all hardware to manufacturer’s torque specifications; verify panel stability and drop distance after installation.

- If integrated with safety-interlocked doors or movable panels, coordinate the bracket location and clearances with the safety switch or sensor positioning.

- Document the installation as part of the machine guarding record, noting part number 093WH400808 for traceability and maintenance.