Procedures, Devices, Training, and Audits Done Right

Lockout/tagout (LOTO) remains one of the most critical and most frequently misunderstood elements of a manufacturing safety program. Many facilities believe they “have LOTO” because they own locks or have a binder of procedures on file. An effective lockout/tagout program is a system, not a document.

At PowerSafe Automation, we regularly encounter facilities with good intentions but fragmented execution: generic procedures, mismatched devices, inconsistent training, and audits performed only to satisfy a checkbox. These gaps create real exposure — not just to OSHA citations, but to serious injury, downtime, and liability.

If you are building or rebuilding a lockout/tagout program, there are four foundational pillars you must address together:

- Machine-specific LOTO procedures

- Properly selected lockout/tagout devices

- Role-based employee training

- Ongoing audits and program verification

Missing any one of these weakens the entire system.

Why Lockout/Tagout Programs Commonly Fail

Before diving into best practices, it is important to understand where most programs break down.

Common failure points we see include:

- One procedure applied across multiple machines

- Energy sources not fully identified (stored, secondary, or gravity)

- Lockout devices that do not physically prevent re-energization

- Training that lacks machine-specific context

- Annual audits performed without observation

From a regulatory standpoint, intent does not matter. Programs are evaluated based on whether hazardous energy is effectively controlled every time servicing or maintenance occurs.

1. Lockout/Tagout Procedures Must Be Machine-Specific

A compliant and usable lockout/tagout program starts with accurate, machine-specific procedures.

What a Compliant Procedure Must Include

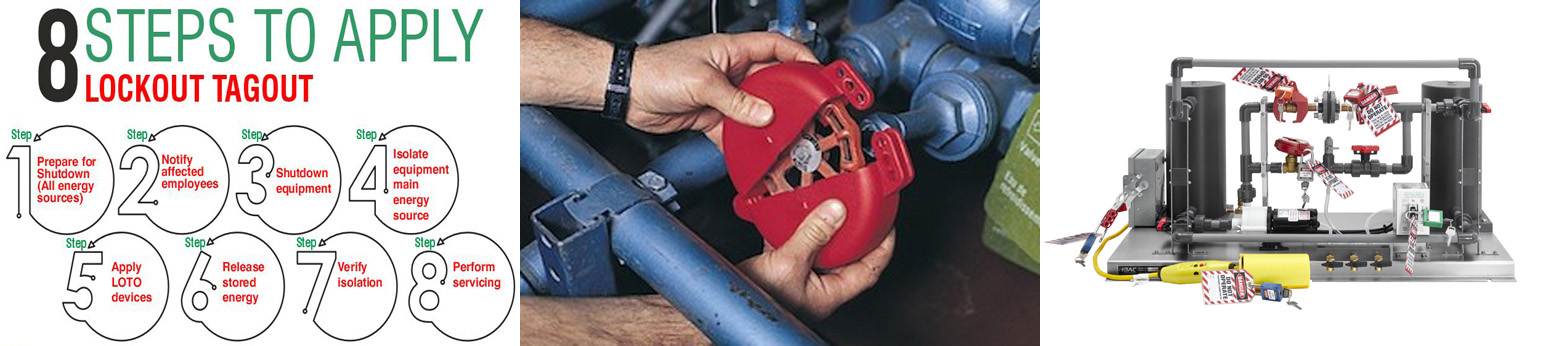

Under OSHA 29 CFR 1910.147, each procedure must clearly document:

- All hazardous energy sources (electrical, pneumatic, hydraulic, mechanical, thermal, gravity)

- Exact energy-isolation points

- Proper shutdown sequence

- Lockout device application steps

- Verification of zero-energy state

- Safe restart process

Common Procedure Gaps

- Generic templates reused across equipment

- Missing secondary or stored energy sources

- Procedures written without maintenance input

- No photos or diagrams of isolation points

PowerSafe Best Practice

Effective procedures are:

- Developed at the machine — not from drawings alone

- Verified with maintenance and engineering personnel

- Illustrated with photos or schematics

- Written in clear, task-based language

A simple test: Could a newly authorized employee safely lock out this machine using only the procedure?

2. Lockout/Tagout Devices Must Match the Hazard

Owning lockout devices does not guarantee energy control. Devices must be correctly selected, applied, and standardized.

Device Selection Matters

Each energy-isolating device must be:

- Capable of being locked in the OFF or safe position

- Durable for the environment

- Clearly identifiable and dedicated to lockout use

Common device categories include:

- Electrical disconnect lockouts

- Valve lockouts (ball, gate, butterfly)

- Pneumatic and hydraulic lockouts

- Group lockout hasps and boxes

Device-Related Risks We See

- Tags used without locks when locks are feasible

- Locks that can be bypassed or removed without tools

- Inconsistent lock colors or personal identification

- No defined group lockout process

PowerSafe Best Practice

A robust LOTO program includes:

- Standardized locks and tags

- Clearly defined personal lock ownership

- Group lockout procedures for multi-person tasks

- Device selection verified during procedure development

3. Lockout/Tagout Training Must Be Role-Based

Training is not about awareness alone — it is about authorization, competency, and accountability.

Employee Categories Matter

A compliant program distinguishes between:

- Authorized employees – perform lockout/tagout

- Affected employees – operate or work near locked-out equipment

- Other employees – present in the area

Each group requires different training content and depth.

Training Gaps That Create Risk

- Same training delivered to all employees

- No documentation of authorized personnel

- No hands-on, machine-specific instruction

- No retraining after equipment changes or incidents

PowerSafe Best Practice

Effective LOTO training includes:

- Classroom and hands-on components

- Machine-specific examples tied to procedures

- Clear authorization records

- Defined retraining triggers

If an employee applies a lock, they must fully understand the energy they are controlling and the consequences of failure.

4. Lockout/Tagout Audits Are a Requirement — Not a Formality

Annual lockout/tagout audits are one of the most overlooked — and most cited — requirements.

What a LOTO Audit Actually Involves

A proper audit includes:

- Reviewing each machine-specific procedure

- Observing authorized employees performing lockout

- Interviewing employees with their understanding

- Documenting deficiencies and corrective actions

A LOTO audit is not:

- A desk review

- A sign-off without observation

- A one-time exercise

Audit Best Practices

High-performing facilities use audits to:

- Validate procedure accuracy

- Confirm training effectiveness

- Identify drift in real-world execution

- Demonstrate due diligence and continuous improvement

How Lockout/Tagout Fits Into a Broader Safety Strategy

Lockout/tagout should not exist in isolation. The strongest programs integrate LOTO with:

- Machine risk assessments

- Safeguarding and interlock design

- Maintenance standard work

- Engineering documentation

- Overall safety culture initiatives

At PowerSafe Automation, we view lockout/tagout as a critical control layer within a larger machine-safety and risk-reduction strategy — not just a compliance requirement.

Build a System — Not a Binder

A lockout/tagout program only works if it functions on the shop floor, under real conditions, with real people.

When building or improving your program, focus on:

- Accurate, machine-specific procedures

- Proper devices that physically control energy

- Meaningful, role-based training

- Regular, documented audits

If one element is weak, the entire system is compromised.