Challenge: Unsafe Operator Exposure Around Moving Gantry Systems

Customer located in Elkhart, IN associated with the Wood Manufacturing & CNC Routing industry operated a high-speed CNC router system for precision cabinetry, but their legacy safety setup lacked the real-time adaptability needed for operator presence detection. Traditional light curtains and physical guarding either limited productivity or failed to provide dynamic protection.

With large gantry travel, risk areas varied across the workspace. Operators frequently needed close interaction with the table for loading and unloading, presenting safety blind spots.

Solution: Smart Zoning with Inxpect 3D Safety Radar

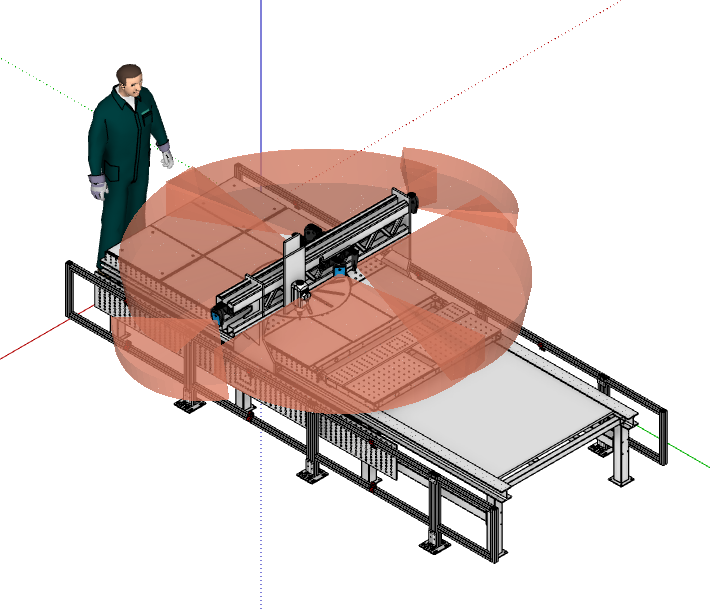

PowerSafe Automation recommended and installed the Inxpect LBK System, a cutting-edge 3D radar-based safety sensor that uses FMCW radar technology to:

-

Detect human presence within the configurable safety zone

-

Ignore dust, wood debris, and vibration—unlike standard optical sensors

-

Provide dynamic protection without interrupting material flow

The system was configured for dual-zone monitoring (warning and shutdown zones), and visualized in the PowerSafe engineering layout to show precise volumetric coverage.

Results: Safer Workflow with Zero Downtime

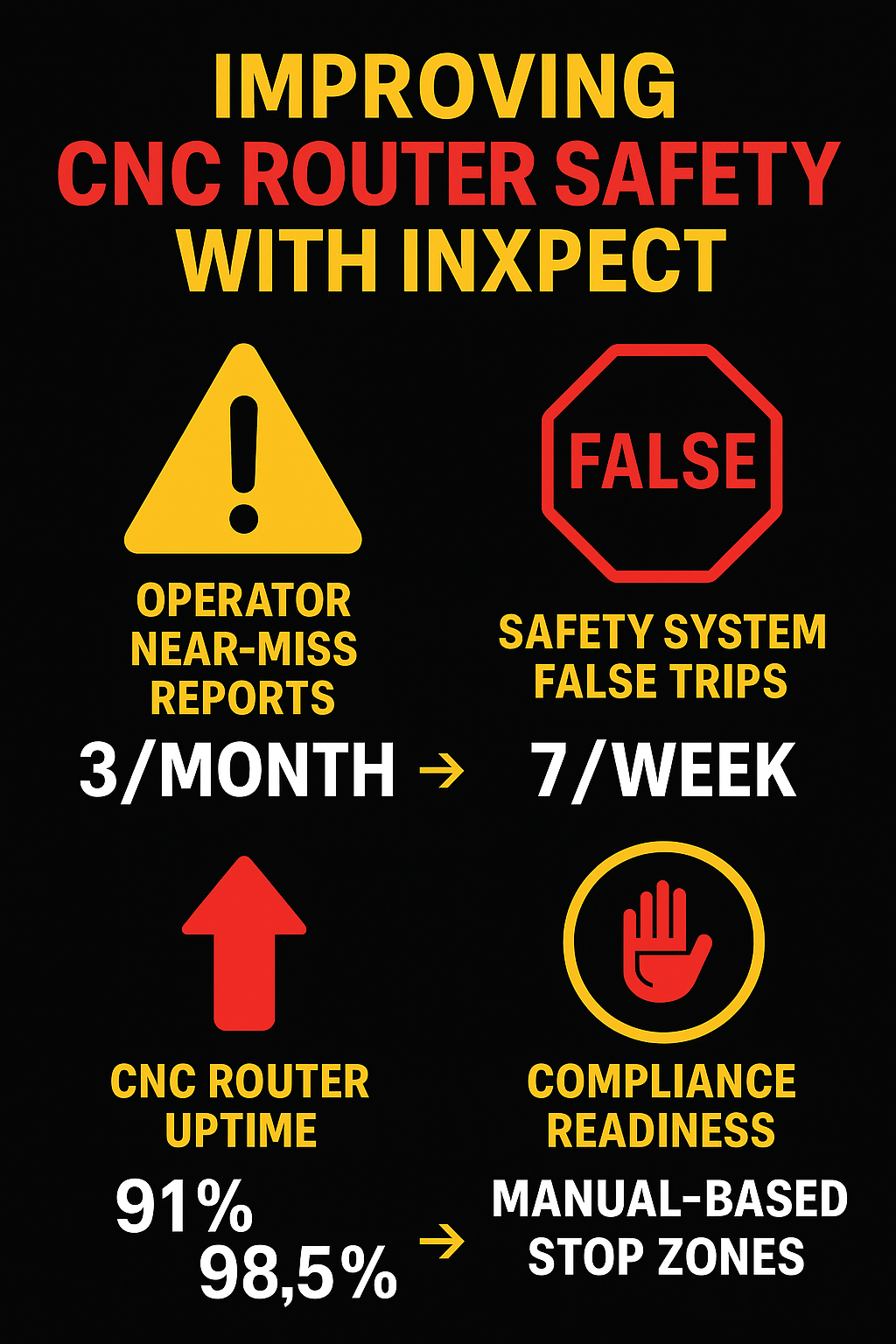

After deployment, the facility reported measurable safety and productivity improvements:

| Metric | Before | After Inxpect Integration |

|---|---|---|

| Operator Near-Miss Reports | 3/month | 0/month |

| Safety System False Trips | 7/week | <1/week |

| CNC Router Uptime | 91% | 98.5% |

| Compliance Readiness | Manual shutdown | Zone-based stop zones |

Ready to Upgrade CNC Safety?

Contact PowerSafe Automation to schedule a safety radar assessment