On-Site Assessments in Minnesota

SERVING MINNESOTA'S LEADING MANUFACTURERS

Minimize Risk. Maximize Safety.

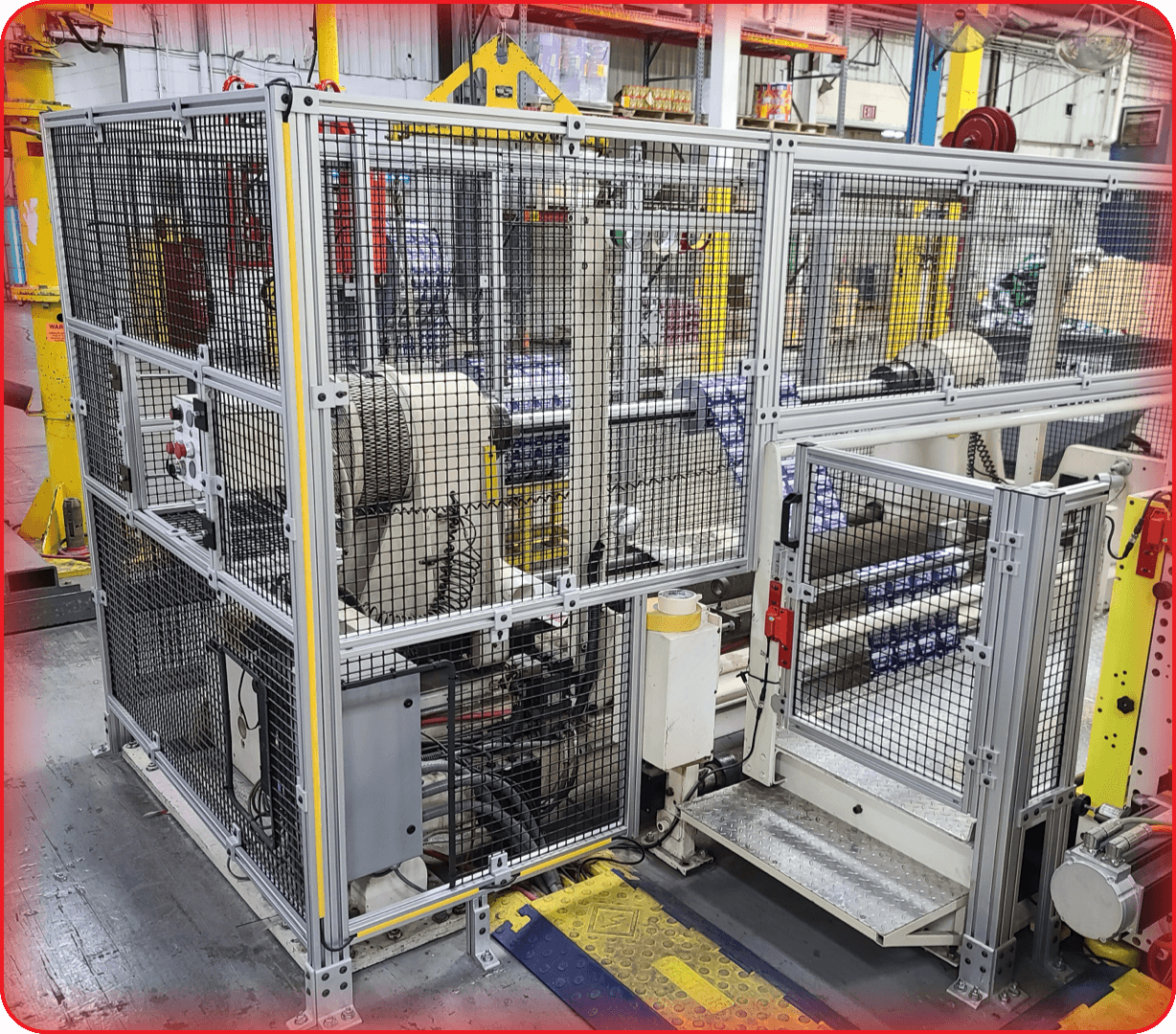

Unlike vendors who sell fencing or off-the-shelf parts, we work directly with your team to design custom machine guarding solutions built around your equipment and process.

From assessment to final installation, our engineer-led turnkey approach keeps your machines compliant and operations running smoothly, without adding to your workload.

PowerSafe Automation offers comprehensive machine guarding systems tailored for legacy equipment.

On-Site Assessment Process

An Applications Engineer visits your site to assess machine guarding needs alongside your team, evaluating key factors like hazard mitigation, accessibility, and ergonomic risks to develop a fully customized guarding solution.

Our team will create concept sketches with dimensions, capture photos and/or video, and determine stop behaviors, then send the package to a design team member.

Following the assessment, our engineers create detailed 3D CAD models and a scope of work for your facility, focusing on engineered safety solutions over administrative controls. You’ll receive a full turnkey quote that includes design presentations, materials, installation plans, integration options, schematics, and recommended spare parts for ongoing maintenance.

Ensure a Safer Work Environment through Strategic Risk Reduction

Ready to protect your people? Contact an Application Engineer at PowerSafe Automation to get started on your next machine safety project.